Electrostatic adsorption production method for reinforce panels

A technology of electrostatic adsorption and production methods, which is applied in the direction of electrical components, printed circuits, printed circuit manufacturing, etc., and can solve the problems of polluting the bare die of the reinforcing sheet, increasing the process of the reinforcing sheet, and increasing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

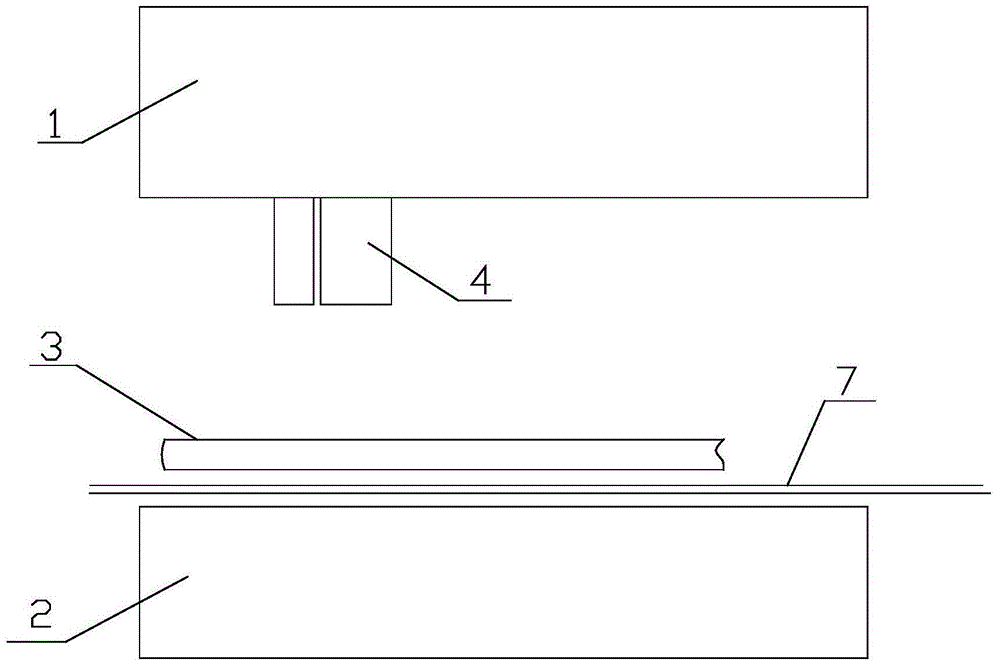

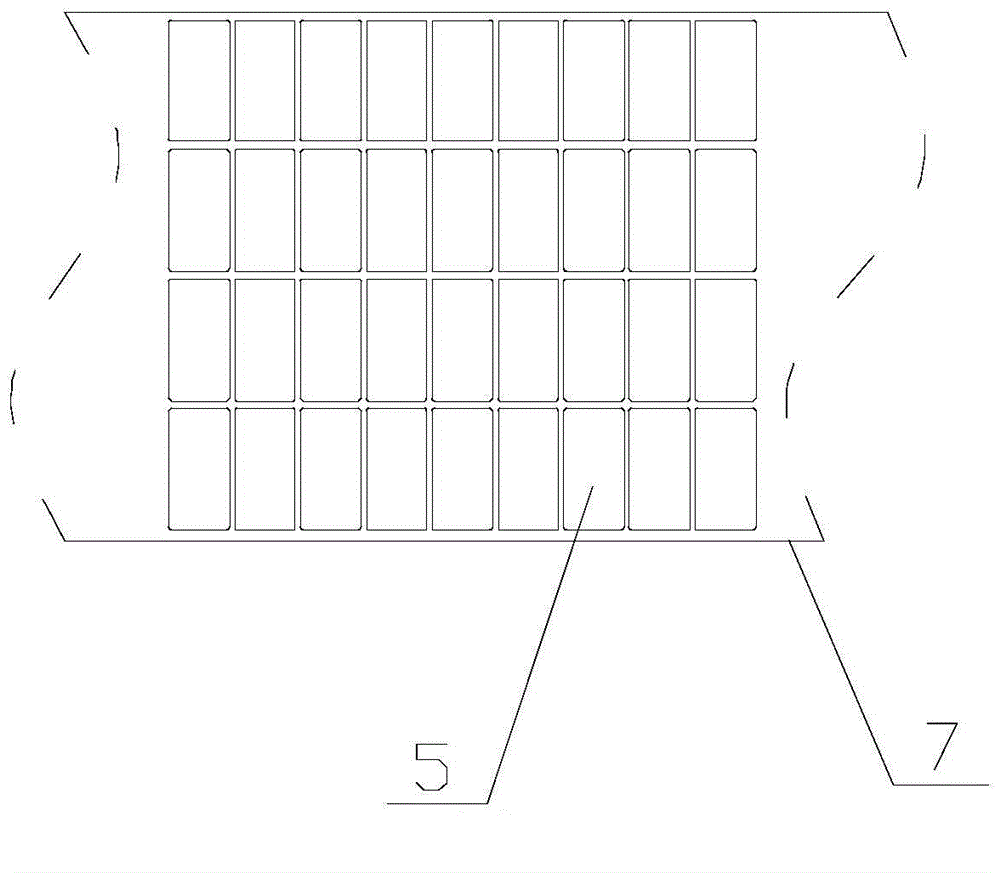

[0016] like Figure 1 to Figure 4 As shown, the upper mold 1 is provided with: forming knives 4, and the reinforcing sheet forming knives can be one or more combinations.

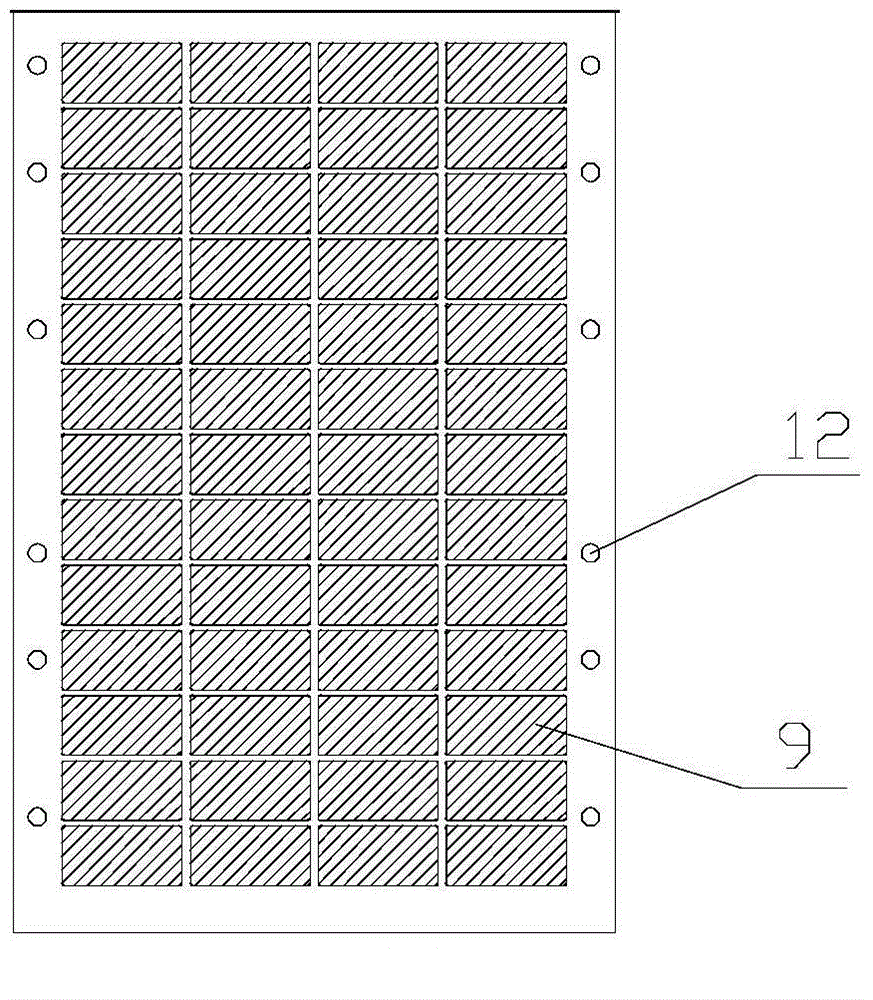

[0017] The jig 10 is provided with: a positioning column 11, a reinforcing sheet placement hole 12, and a magnet 8; the magnet 8 is located below the reinforcing sheet placement hole 12, and its function is to absorb the steel sheet 5, so as to facilitate tearing off the static film 7.

[0018] The thermosetting adhesive 9 is regular typesetting, and is consistent with the typesetting of the steel sheet 5; there are positioning holes 12 on the thermosetting adhesive carrier tape, which match with the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com