Production method for concrete

A manufacturing method and concrete technology, which is applied to clay preparation devices, chemical instruments and methods, mixers, etc., can solve the problems of increasing or decreasing the degree of freedom of concrete, and achieve the effect of increasing the degree of freedom and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

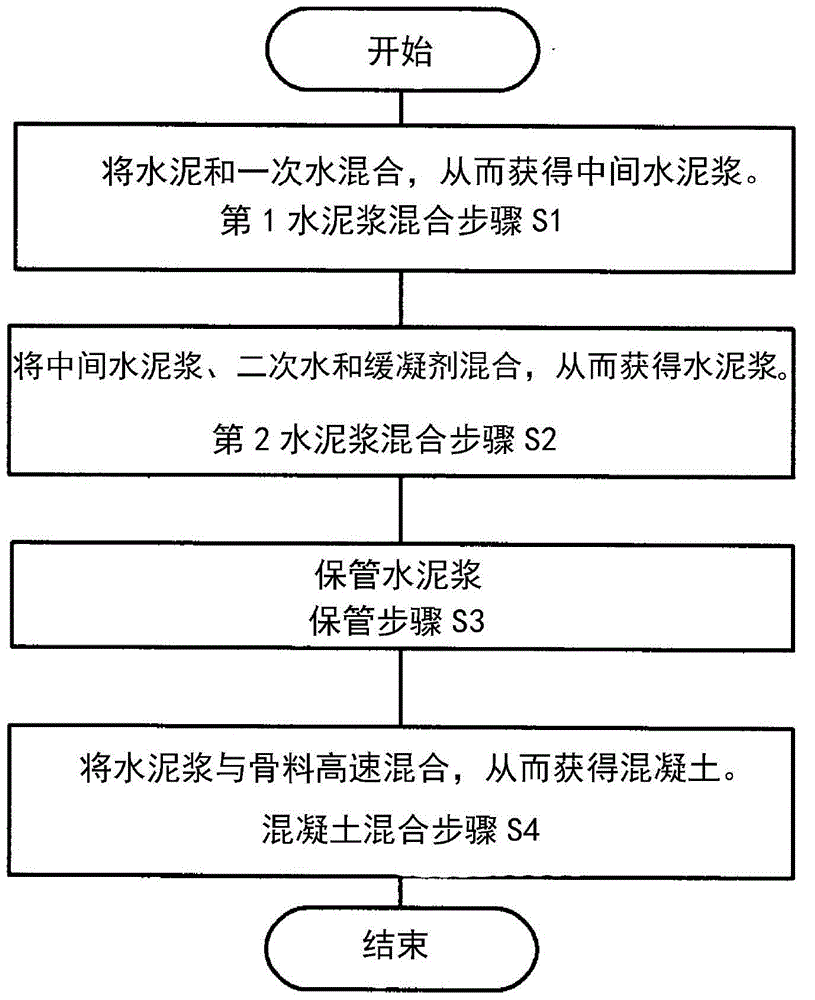

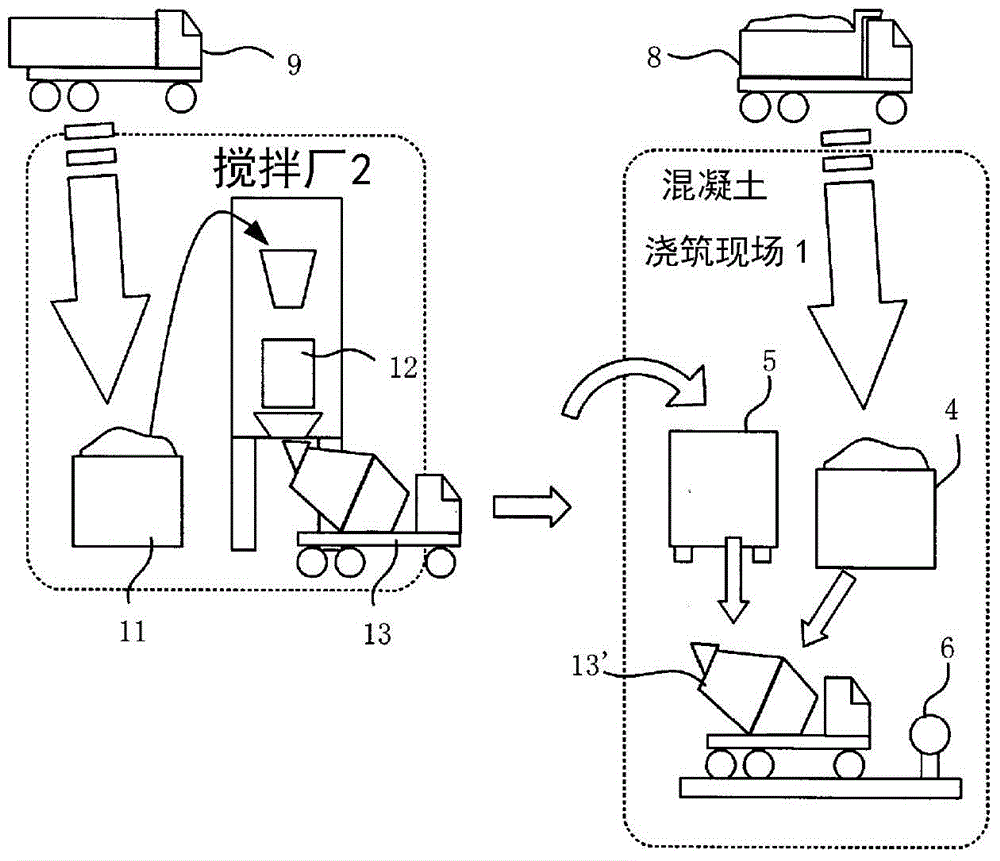

Method used

Image

Examples

Embodiment 1

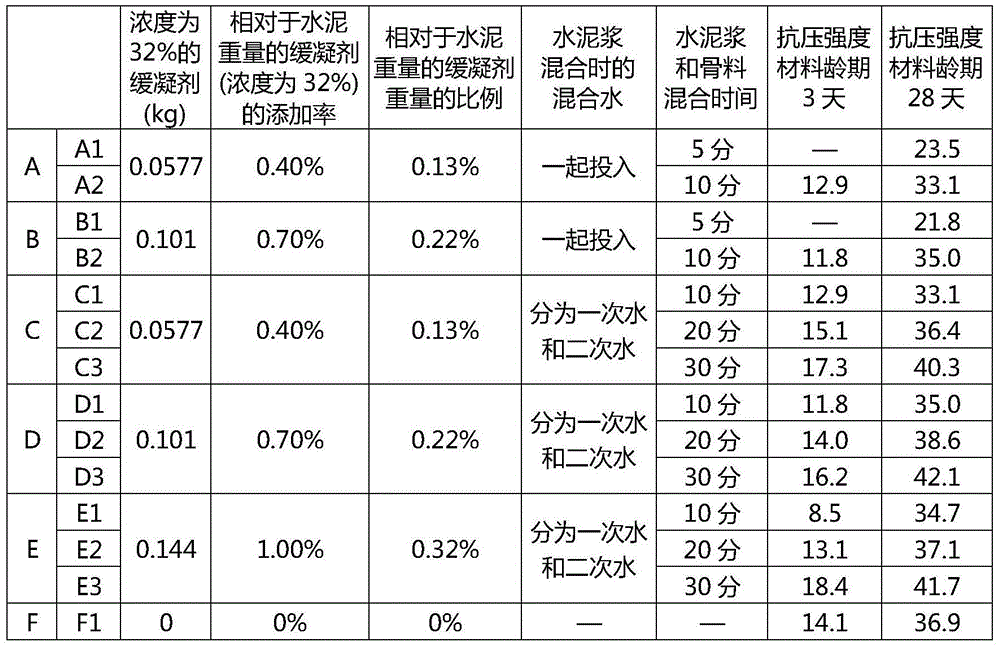

[0028] In the following experiments, it was confirmed that the concrete production method of the present invention can control the setting and hardening, and that the setting retarding effect of the retarder can be released by the physical action caused by mixing.

[0029] (1) General conditions

[0030] When various conditions are changed to produce concrete, the conditions are common for materials other than retarders. That is, the materials used and their ratios are constant as shown below.

[0031] [Table 1]

[0032]

mixed water

cement

fine aggregate

Coarse aggregate

AE additives

Concrete 1m 3 Material weight (kg)

167

361

889

937

3.61

0.014

[0033] Note) Surface water is not included in the weight of aggregate.

[0034] [Table 2]

[0035]

mixed water

cement

fine aggregate

Coarse aggregate

AE additives

Material...

Embodiment 2

[0066] The mixing time required to produce concrete varies greatly depending on the type of mixing device. Then, the following experiments were conducted, in which it was confirmed that the effect of the present invention was obtained even when the type of the mixing device was changed and the time of the concrete mixing step was changed.

[0067] (1) General conditions

[0068] When various conditions are changed to manufacture concrete, the materials and ratios to be used are constant, as described below.

[0069] [Table 4]

[0070]

mixed water

cement

fine aggregate

Coarse aggregate

AE additives

Concrete 1m 3 Material weight (kg)

167

361

831

1023

3.61

0.0325

[0071] Note) Surface water is not included in the weight of aggregate.

[0072] [table 5]

[0073]

mixed water

cement

fine aggregate

Coarse aggregate

AE superplasticizer

AE additives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com