Charged particle multi-beamlet lithography system and cooling arrangement manufacturing method

A charged particle beamlet, charged particle technology, applied in circuits, discharge tubes, electrical components, etc., can solve problems such as reduced pattern accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is a description of various embodiments of the invention, given by way of example only, with reference to the accompanying drawings.

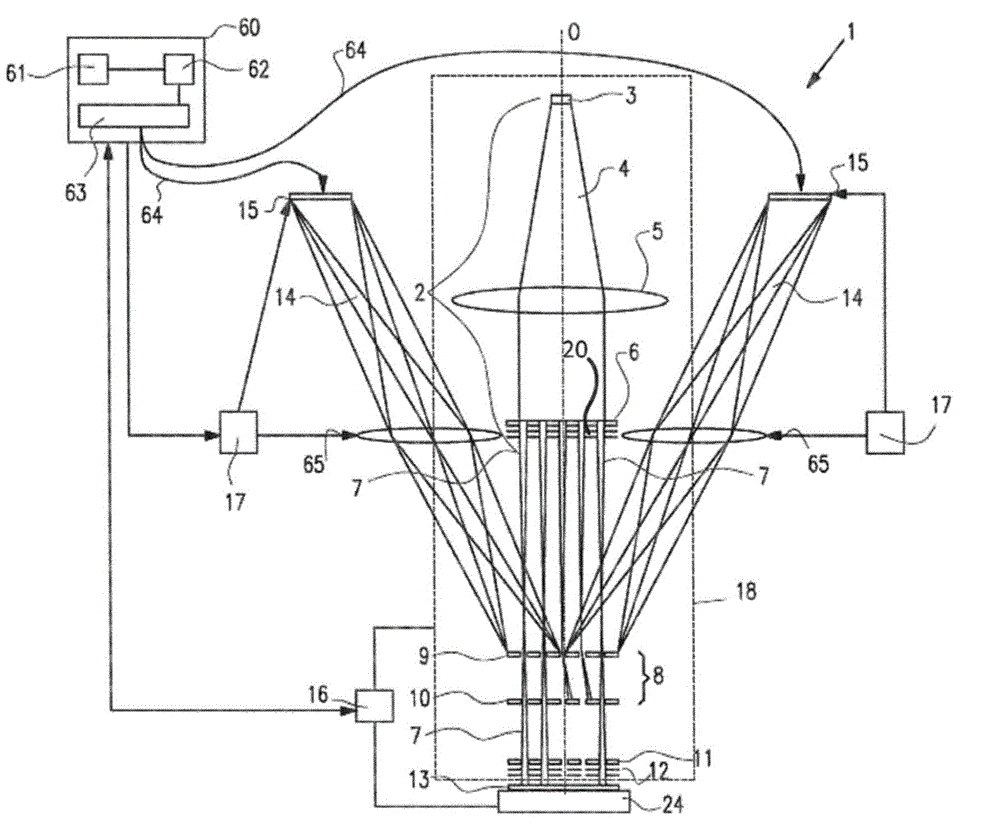

[0036] figure 1 A simplified schematic embodiment of an embodiment of a charged particle lithography apparatus 1 is shown. Such lithographic systems are described, for example, in U.S. Patent Nos. 6,897,458 and 6,958,804 and 7,019,908 and 7,084,414 and 7,129,502, U.S. Patent Application Publication No. 2007 / 0064213, and Serial Nos. 61 / 031,573 and 61 As described in co-pending applications No. / 031,594 and 61 / 045 / 243 and 61 / 055,839 and 61 / 058,596 and 61 / 101 / 682, which are assigned in their entirety to all of the present invention are incorporated herein by reference in their entirety.

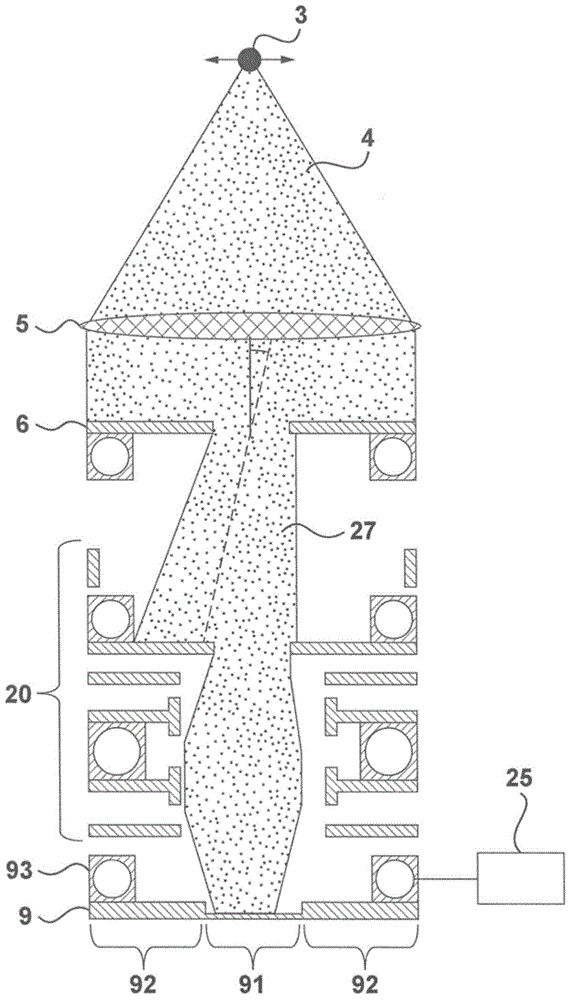

[0037] exist figure 1 In the embodiment shown in , the lithographic apparatus 1 comprises a beamlet generator 2 for generating a plurality of beamlets, a beamlet modulator 8 for patterning the beamlets to form modulated beamlets, and a beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com