Unpowered driven air filtering screen cleaning device

An air filter and cleaning device technology, applied in the field of cleaning devices and air filter cleaning devices, can solve the problems of affecting air flow, large power consumption, complex structure, etc., and achieve air flow improvement, energy saving, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

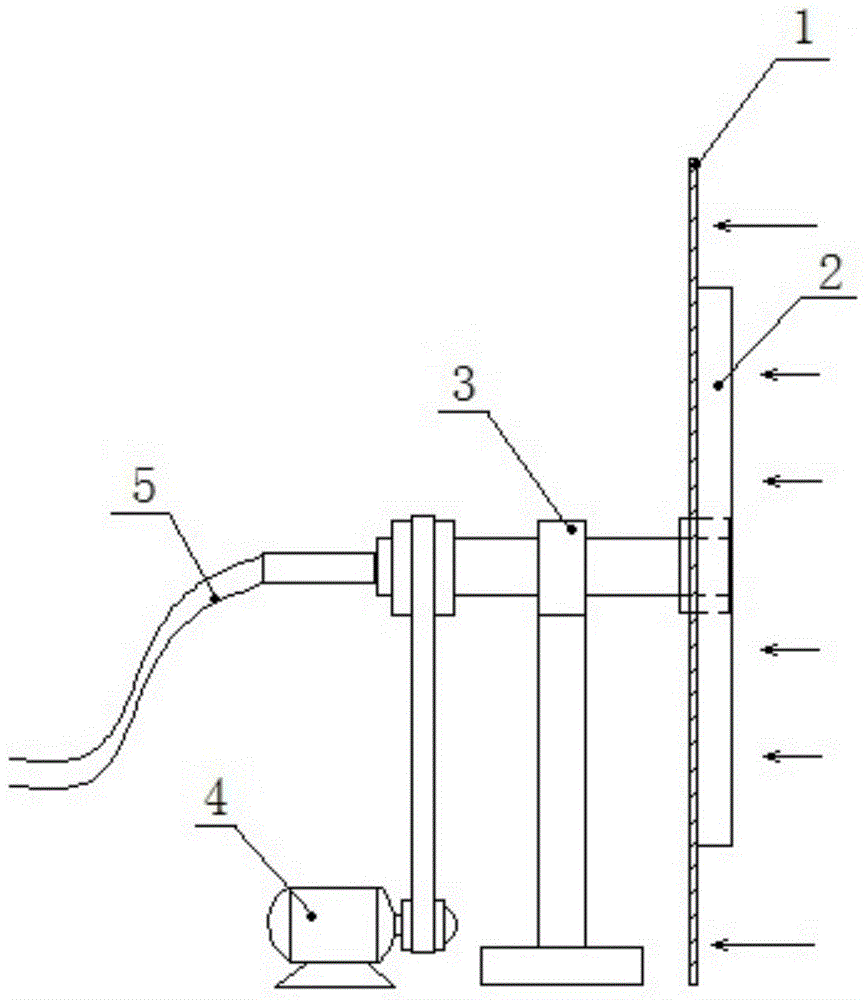

[0016] figure 2 Shown is the structural representation of the present invention.

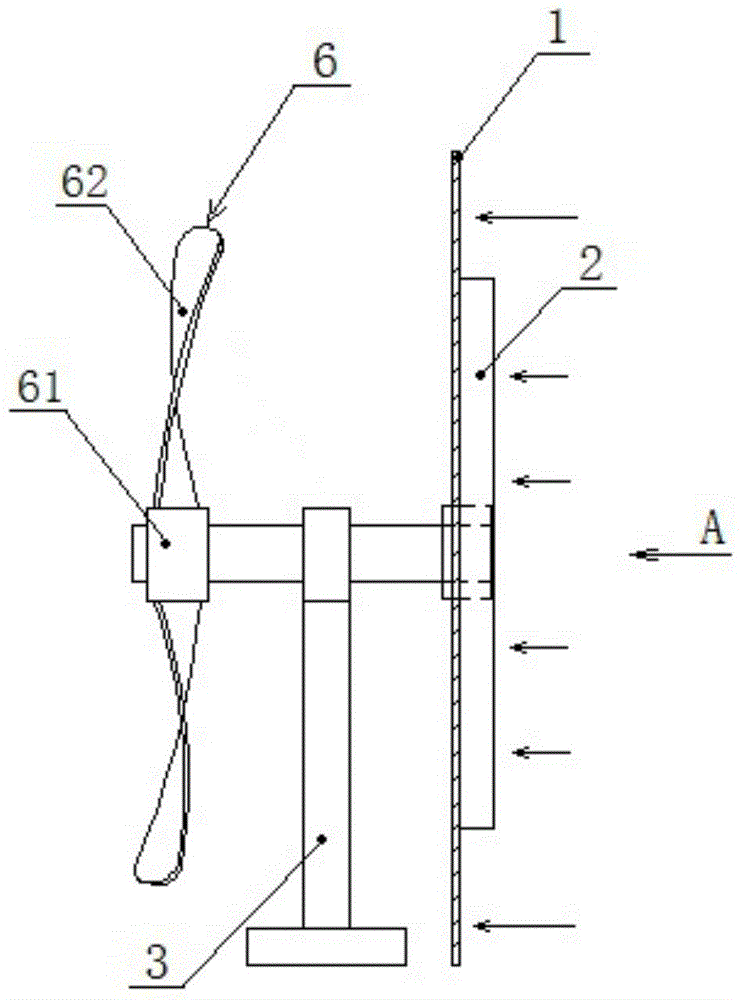

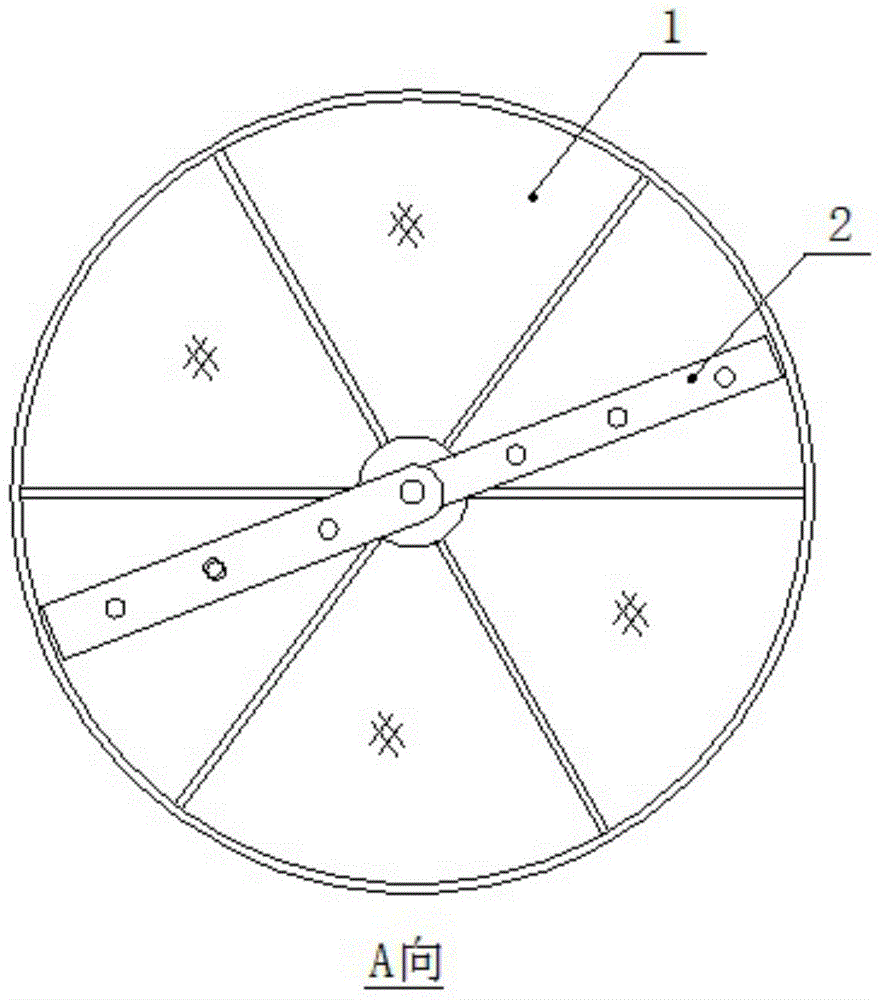

[0017] image 3 Shown is the invention attached figure 2 The schematic diagram of A direction.

[0018] The present invention comprises metal spacer 1 and fan cylinder 2, and fan cylinder 2 is positioned at the outside of metal spacer 1, is fixed with wind impeller 6 by support 3 in the inner side of metal spacer 1, and wind impeller 6 is connected with fan cylinder 2 coaxially.

[0019] The wind impeller 6 is provided with an impeller body 61 with airfoil blades 62 distributed on its circumference.

[0020] The configuration angle of the airfoil blade 62 is 15°±2.5°.

[0021] There are 9-11 pieces of said airfoil blades 62 .

[0022] The outer side of the air duct 2 is provided with a transparent viewing port.

[0023] Both ends of the air cylinder 2 are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com