A special blade for layered drilling with four fist-shaped blades

A blade and drilling technology, which is applied in the field of special blades for layered drilling with four fist-shaped blades, can solve the problems of easy wear and chip removal of the blade, unsmoothness, and difficulty in ensuring hole accuracy, etc., achieve good bending effect and improve service life , good support and strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

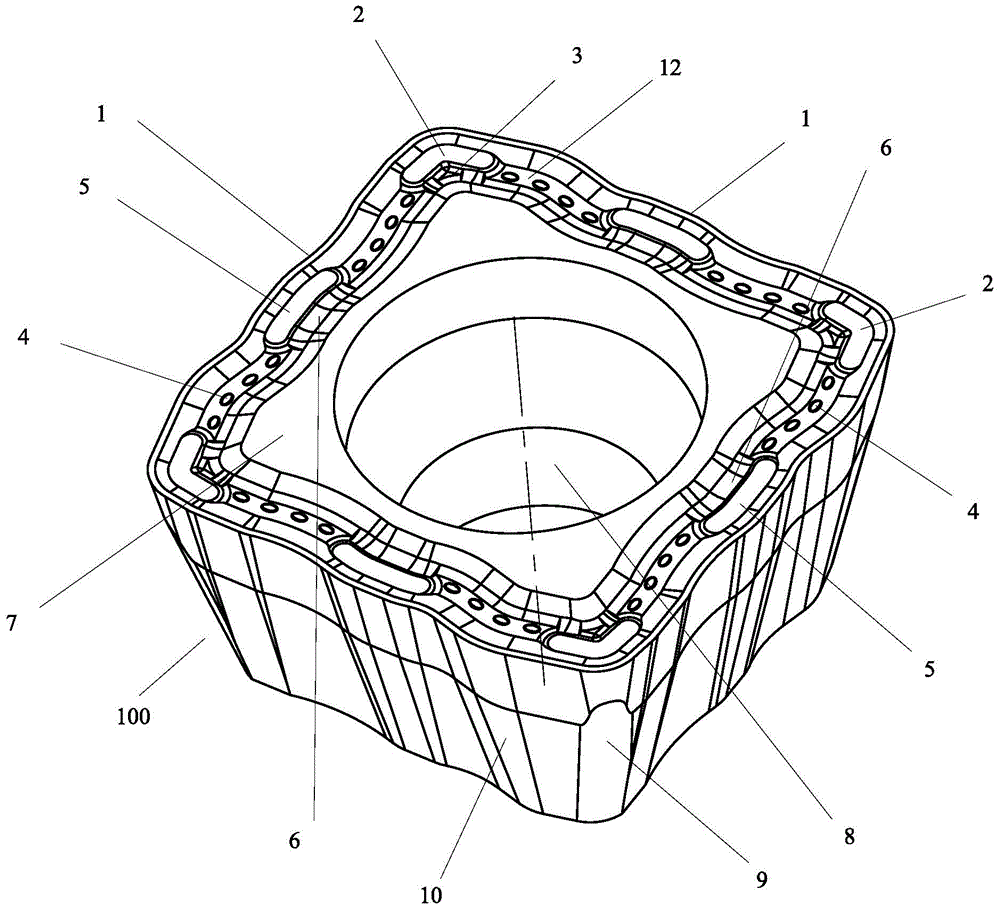

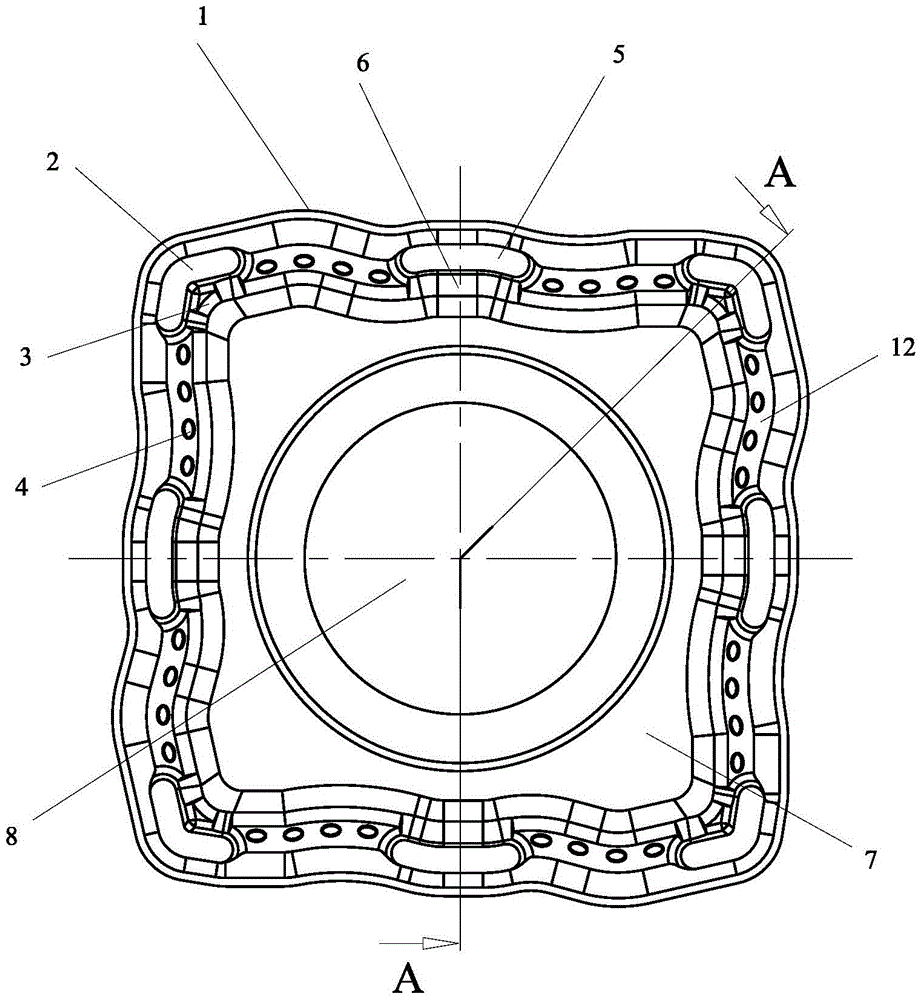

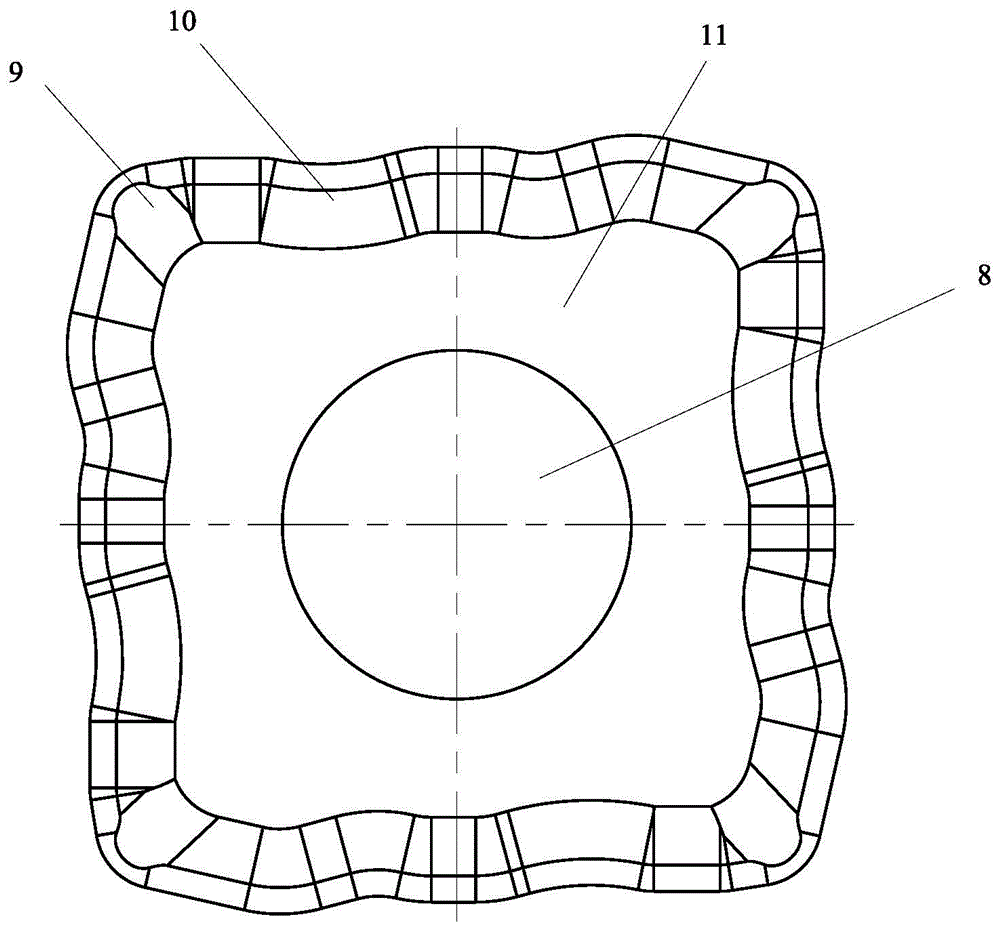

[0042] see Figure 1 to Figure 17 As shown, a four-fold box-shaped edge layered drilling special blade of the present invention includes a roughly regular quadrilateral blade body 100; the blade body 100 has an upper surface, a lower surface, and side surfaces connecting the upper and lower surfaces; the The blade body 100 is provided with a fastening hole 8 through the upper and lower surfaces, and the entire blade can be fixed on the drill body through the fastening hole 8 by a fastening screw, and the periphery of the fastening hole 8 is provided with a front boss 7; The intersecting ridgelines of the upper surface and the side of the insert body 100 form four main cutting edges 1, and the four main cutting edges 1 correspond to the four sides of a regular quadrilateral; the projection of the main cutting edges 1 on a plane is fist-shaped shape, i.e. a clenched fist (eg Image 6 shown), and the two adjacent main cutting edges 1 are 90° rotationally symmetrical with respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com