A CNC milling machine driven by a rack and pinion to move the gantry

A technology of rack and pinion and CNC milling machine, which is applied in the direction of milling machine equipment, milling machine equipment details, large fixed members, etc., can solve the problems of limiting CNC milling machines, increasing costs, labor and time, etc., to eliminate process seams, improve efficiency, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

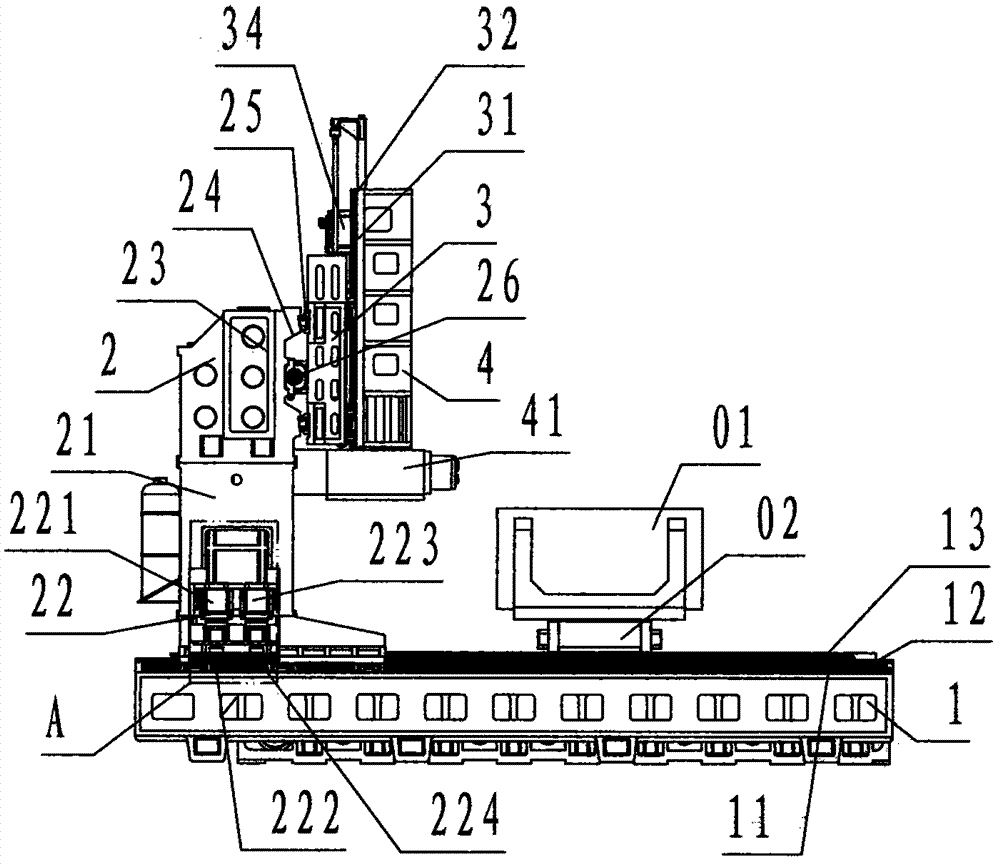

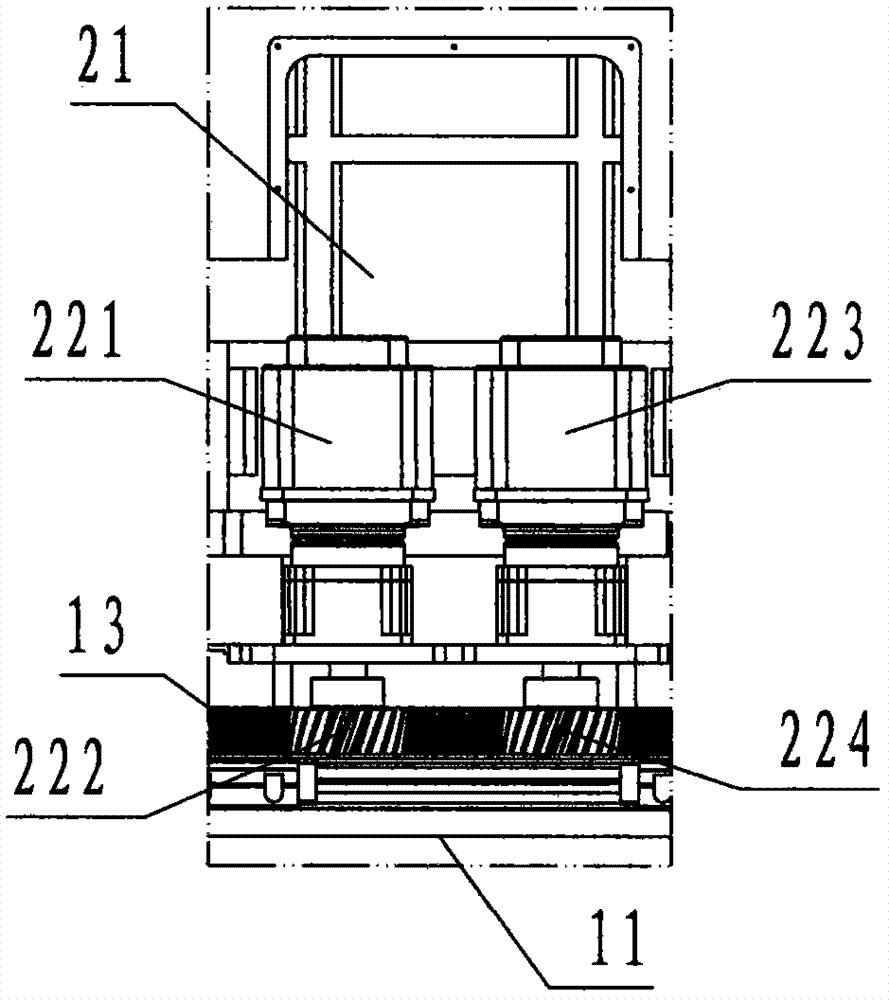

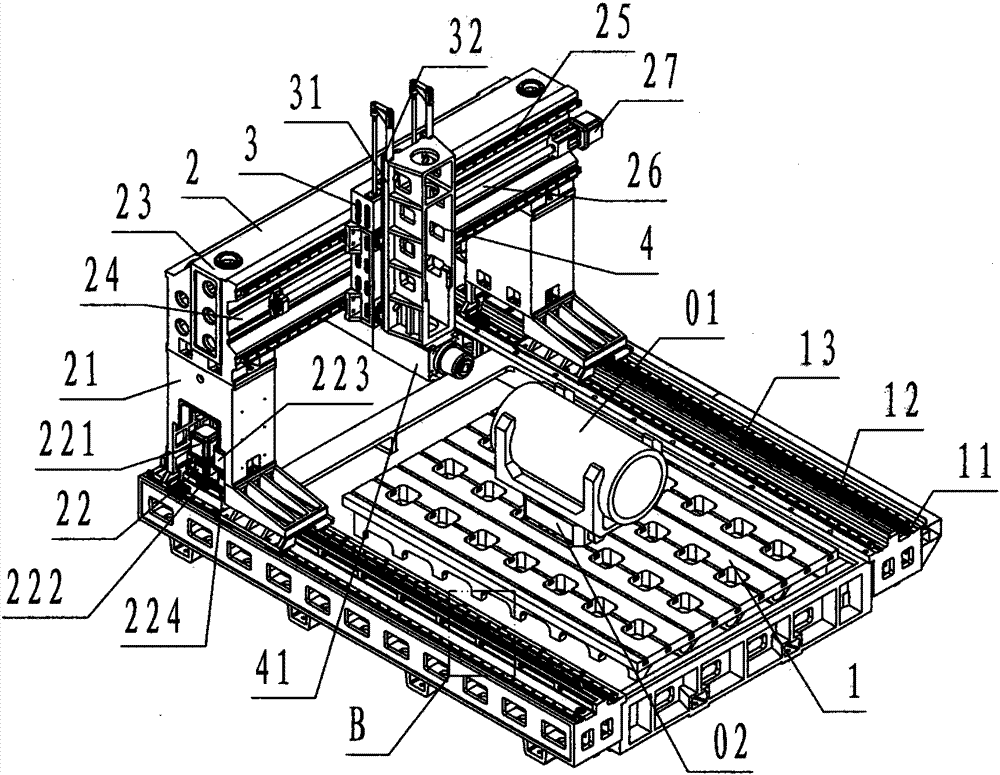

[0025] refer to Figure 1 to Figure 6 , a kind of numerically controlled milling machine that drives the gantry to move by rack and pinion of the present invention, comprises fixed worktable 1, Y movable gantry 2, orthogonal carriage 3, Z carriage 4, wherein: described fixed workbench 1 is top view It is a rectangular cast iron component, and the front and rear sides of the fixed workbench 1 are respectively provided with a rectangular platform in the left and right direction, which is called the Y rail base 11. On the Y rail base 11, there are two rollers parallel to each other and in the left and right directions. The guide rail pair is called the Y rail pair 12, and the helical racks protruding upwards and left and right directions between the two Y rail pairs 12 are called racks 13; The teeth face forward, and the teeth of the rack 13 positioned at the rear of the fixed workbench 1 face backward;

[0026]The Y moving gantry 2 is a door frame-shaped cast iron component, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com