A kind of valve type concrete sheet pile hole forming device and hole forming method

A technology for concrete slabs and hole-forming devices, applied in sheet pile walls, buildings, infrastructure engineering, etc., can solve the problems of size, length and economy being limited by processing and transportation conditions, high vibration and noise, etc. The effect of designing length, improving bearing capacity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below with reference to the accompanying drawings and specific preferred embodiments.

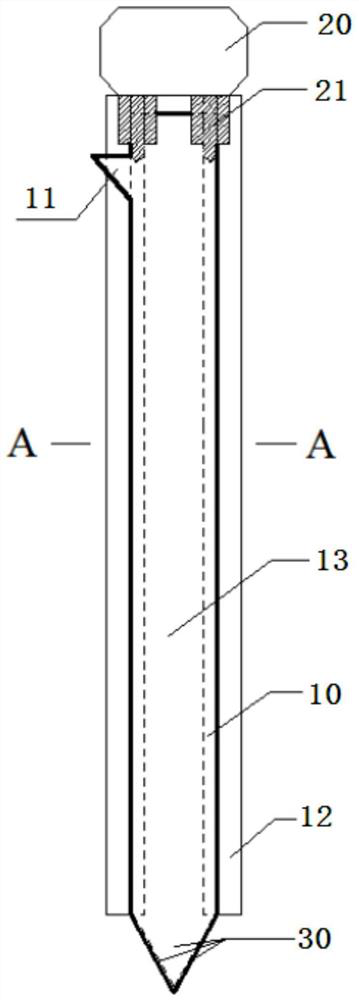

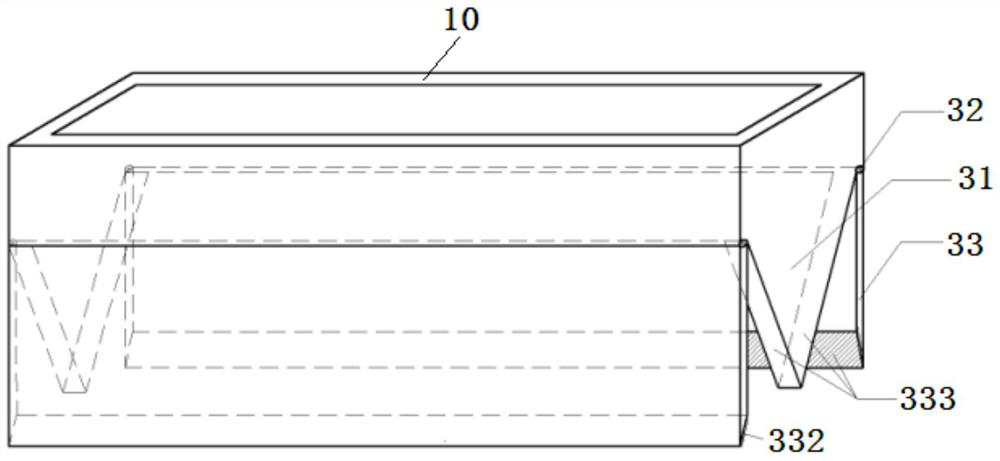

[0047] like figure 1 As shown, a valve type concrete sheet pile hole forming device includes a steel formwork 10 and a valve type pile shoe 30 .

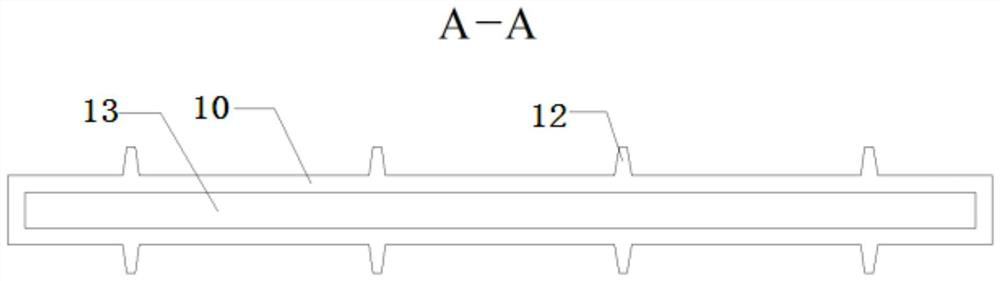

[0048] The center of the steel formwork is provided with a pouring cavity 13 with a rectangular section, and the length-width ratio of the rectangular section of the pouring cavity is increased.

[0049] The top of the steel formwork or the top of the side wall is provided with a concrete pouring sprue 11 .

[0050] like figure 2 As shown, several stiffening plates 12 are preferably uniformly distributed on the outer wall of the steel formwork along the circumferential direction, and both the steel formwork and the stiffening plates are preferably high-strength steel plates. Each reinforced slab is preferably arranged vertically, so the overall rigidity of the steel formwork can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com