Assembly table in led light assembly line

An assembly line and LED lamp technology, applied in the field of machinery, to achieve the effect of improving assembly efficiency and reducing assembly strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

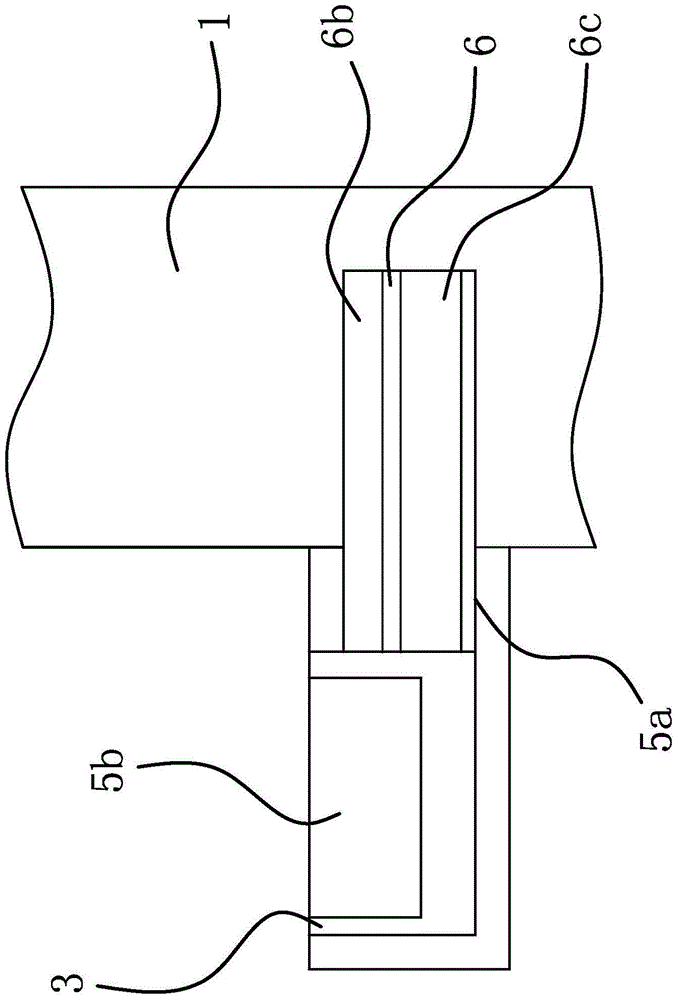

[0078] The LED lamp assembly line is provided with a conveyor belt 1 for conveying semi-finished LED lamps, and the conveyor belt 1 is driven by a common driving motor to translate. The semi-finished LED lights are placed on the conveyor belt 1, and the semi-finished LED lights are transported during the movement of the conveyor belt 1.

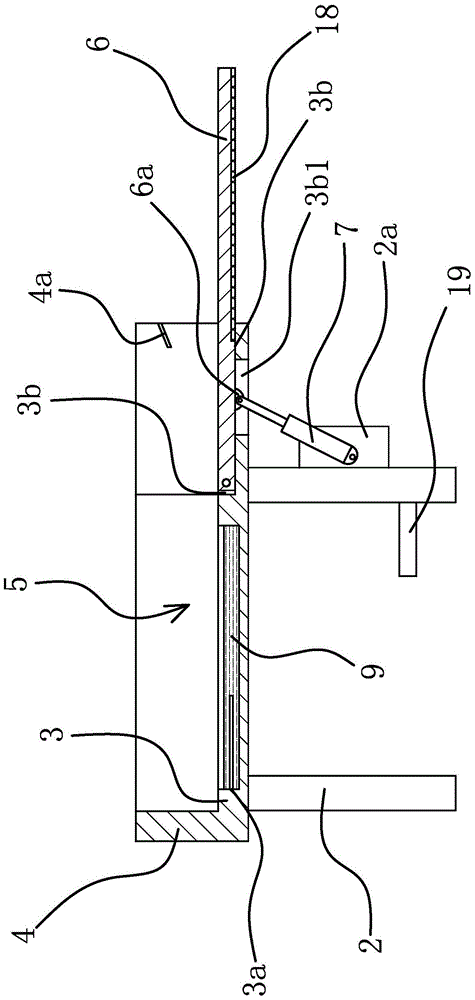

[0079] Such as figure 1 with figure 2 As shown, the assembly table in the LED lamp assembly line is close to the conveyor belt 1 and includes a bracket 2 and a planar assembly table 3 fixedly connected to the bracket 2.

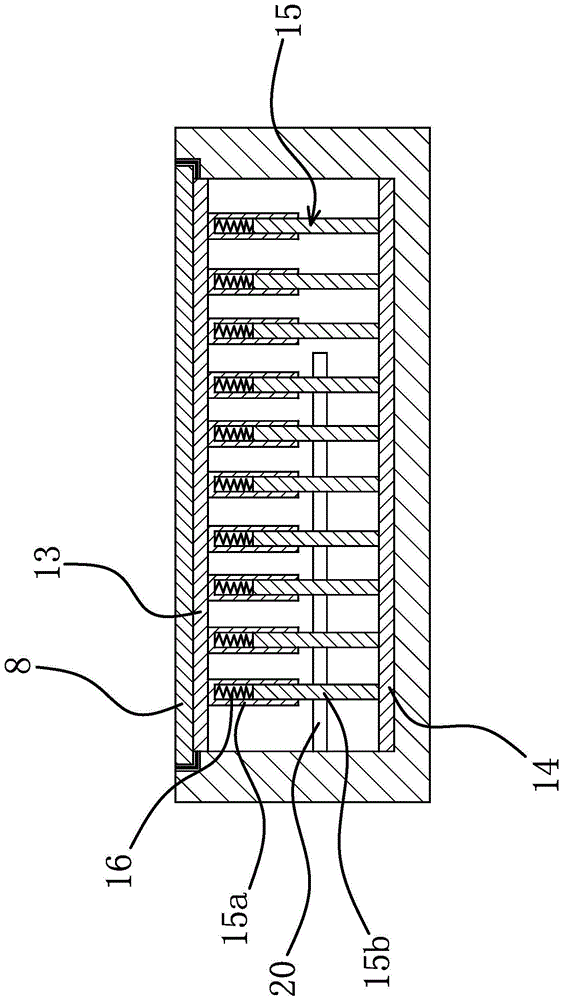

[0080] The edge of the assembly table 3 is fixedly connected with a stopper 4 protruding toward the upper part of the assembly table. Between the stopper 4 and the upper part of the assembly table 3, an assembly cavity 5 for the operator to assemble the LED lamp is formed. 5a and operation port 5b.

[0081] The assembly table 3 also has a feeding plate 6 and a driving member 7. The inner end of the feeding plate 6 is hinged at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com