Automobile brake pad production line

A brake pad and production line technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of poor fixation at the bottom of the equipment, easy deviation of the drilling position, and high cost, so as to improve the precision of tablet pressing and processing efficiency and Improve product quality, improve the uniformity of heat treatment, and improve the effect of grinding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

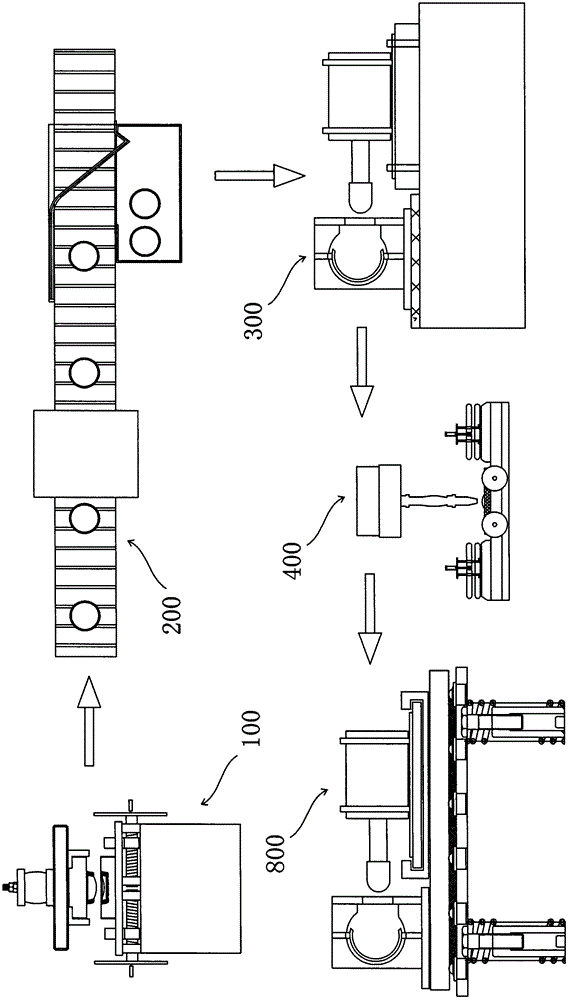

[0032] In order to further describe the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Figure 1-11 A production line for automobile brake pads shown includes a tablet pressing device 100, a heat treatment device 200, a grinding device 300, a drilling device 400, a coding device 800 and a conveying device connecting each device.

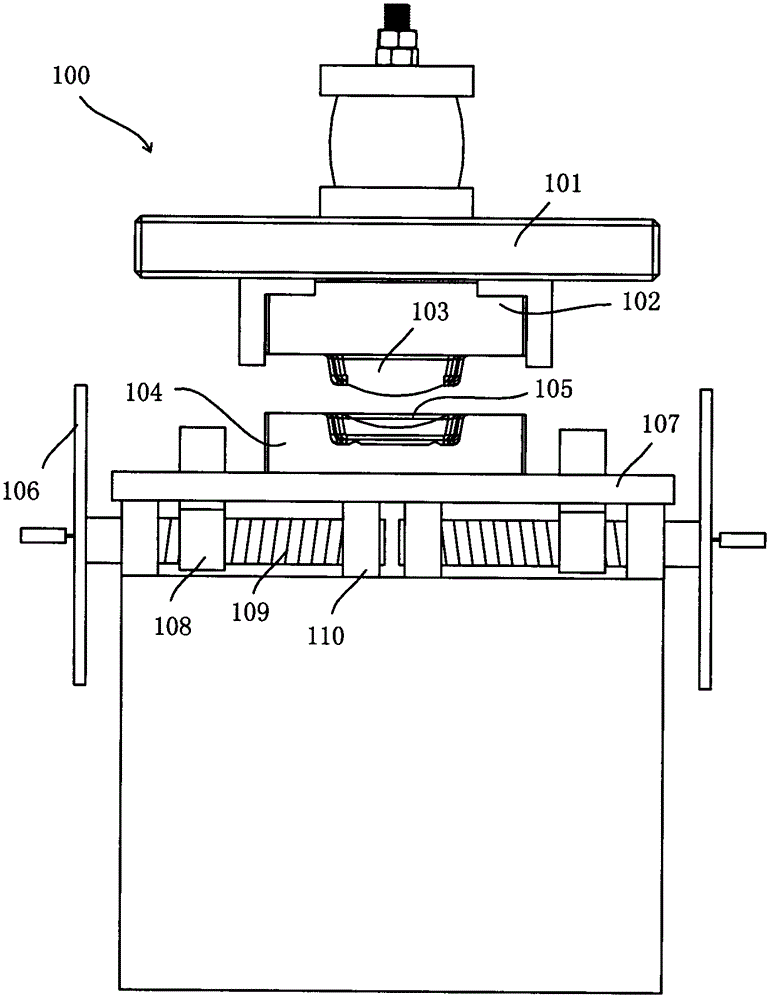

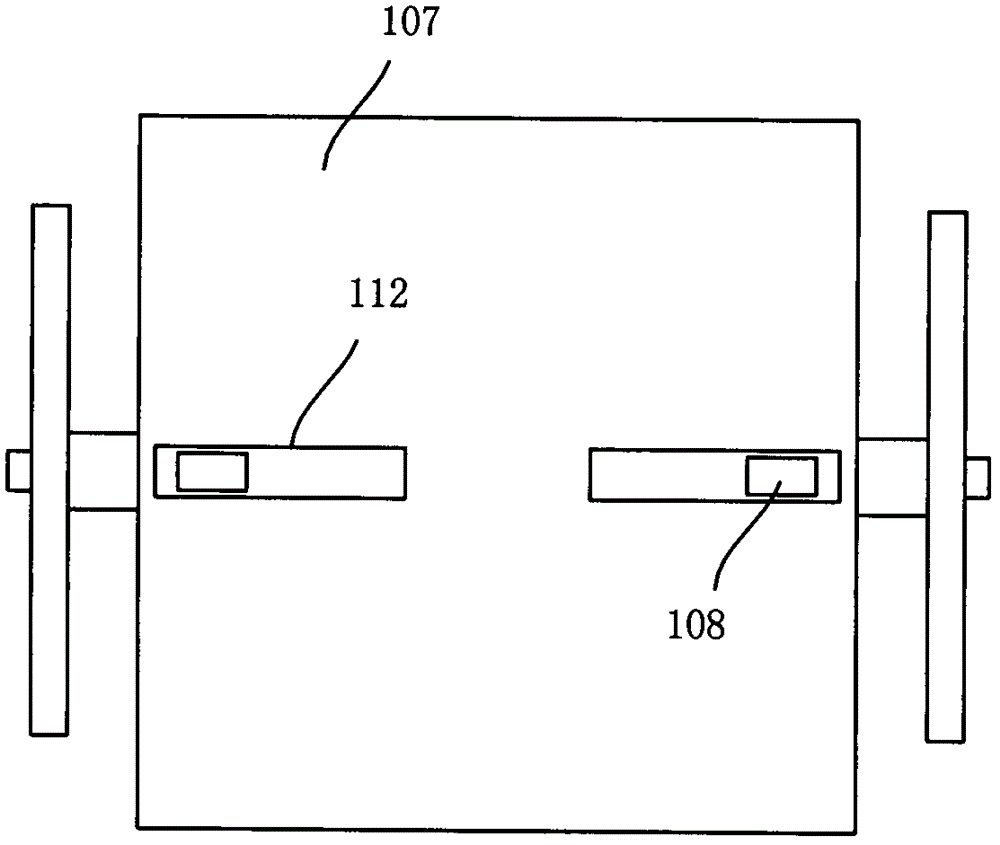

[0033]The tablet pressing device 100 includes an upper die 102 and a lower die 104 , the bottom of the upper die 102 is provided with a brake pad pressing punch 103 , and the upper part of the upper die 102 is provided with a top plate 101 and a first hydraulic press placed on top of the top plate 101 . The lower mold 104 is provided with a brake pad pressing die 105 matched with the brake pad pressing punch 103, the lower die 104 is placed in the die clamping fixture, and the die clamping fixture includes a square first fixing plate 107, the first fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com