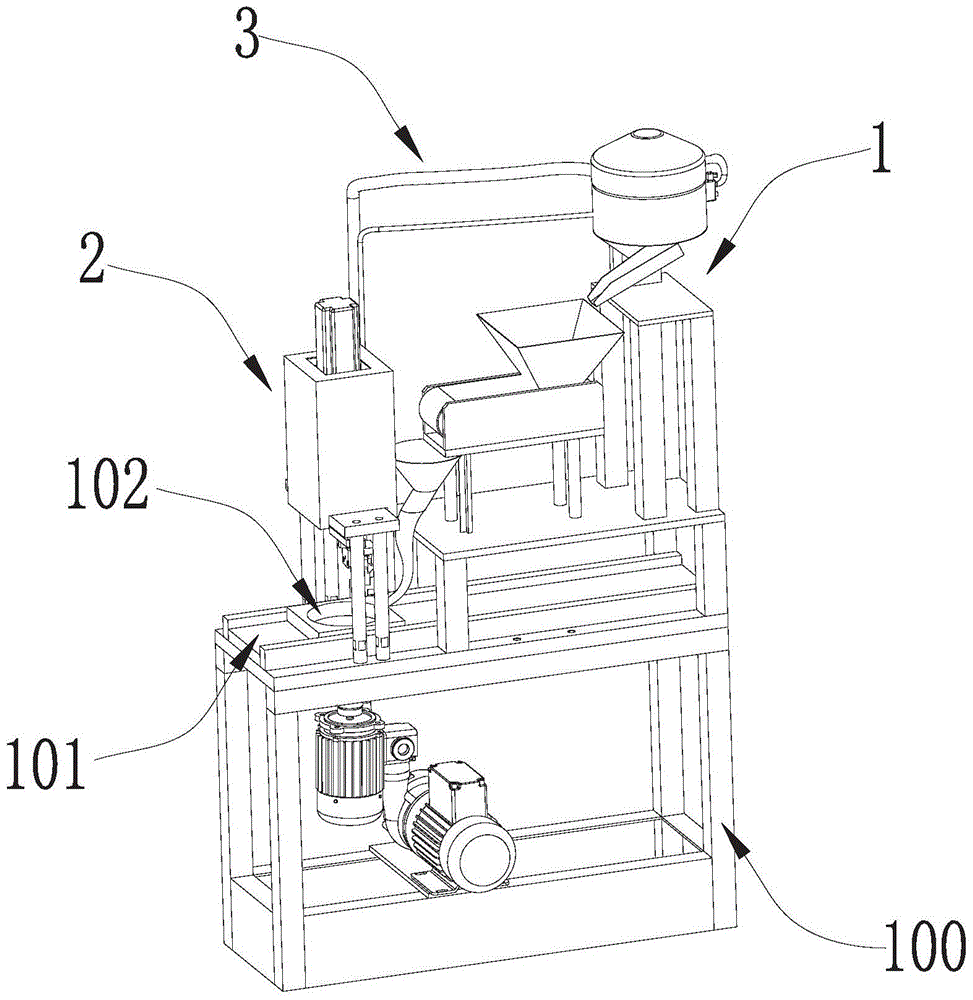

Grinding wheel preparation and spreading device capable of absorbing sand

A sand material and grinding wheel technology, applied in the field of grinding wheel manufacturing equipment, can solve problems such as uneven material distribution, low yield, and influence on normal use, and achieve the effects of maintaining sand material density, reducing production costs, and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

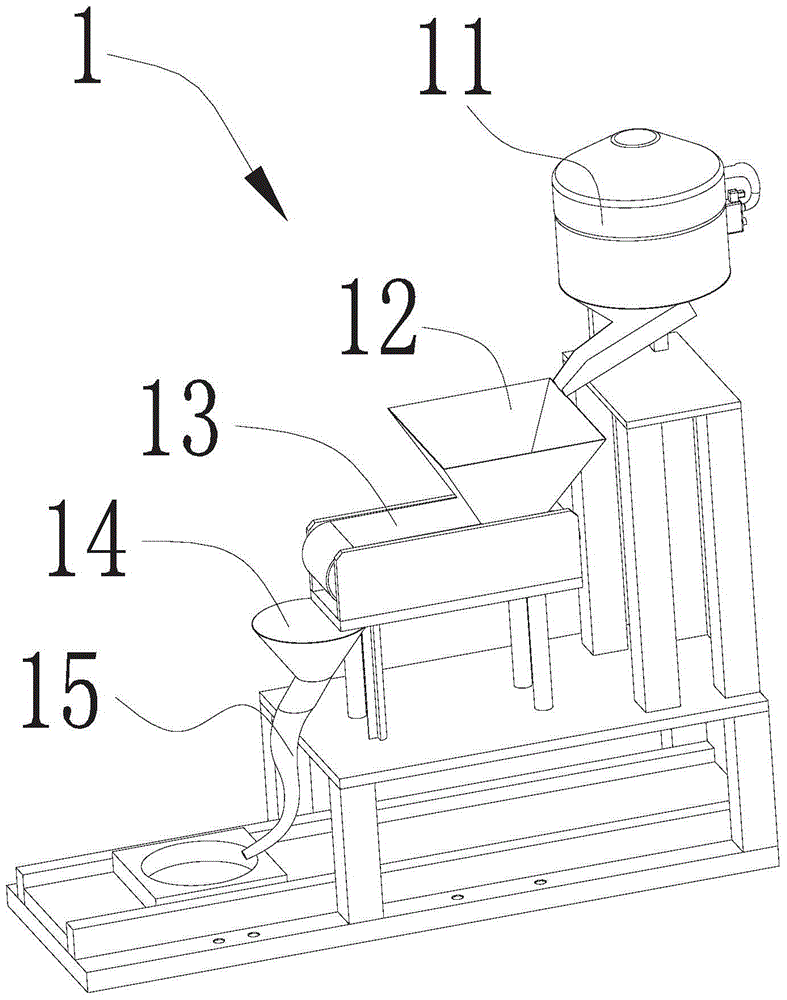

[0046] In the present invention, the operations such as feeding, spreading, and absorbing surplus material in the process of making the grinding wheel are realized through the following steps:

[0047] S1 pours the mixed sand into the storage bin and opens the device;

[0048] The baffle in the S2 storage bin is opened, and the sand flows into the first feeding chamber;

[0049] After S3 passes through the first feeding cavity, the sand material enters the second feeding cavity along the feeding belt, and enters the mold cavity through the feeding elbow;

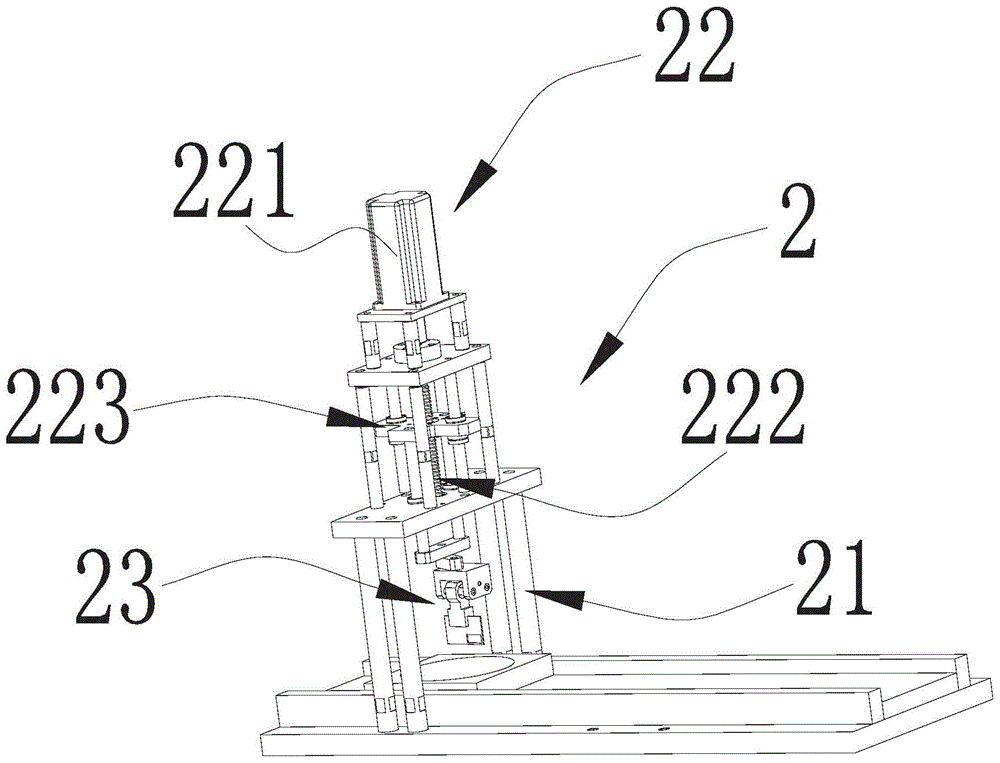

[0050] S4 After filling the mold cavity once, the baffle in the storage bin is closed, the screw motor drives the ball screw to rotate, the screw nut moves downward along the ball screw, and at the same time drives the scraper mechanism to move toward the mold cavity;

[0051] The S5 scraper stays on the surface of the mold cavity, the rotating motor drives the turntable to rotate, the mold cavity in contact with the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com