Sucker type stacking manipulator capable of remaining gap

A suction cup-type, manipulator technology, applied in the field of palletizing manipulators, can solve problems such as scratches, damage, and poor control of clamping force, and achieve the effects of small footprint, stable performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

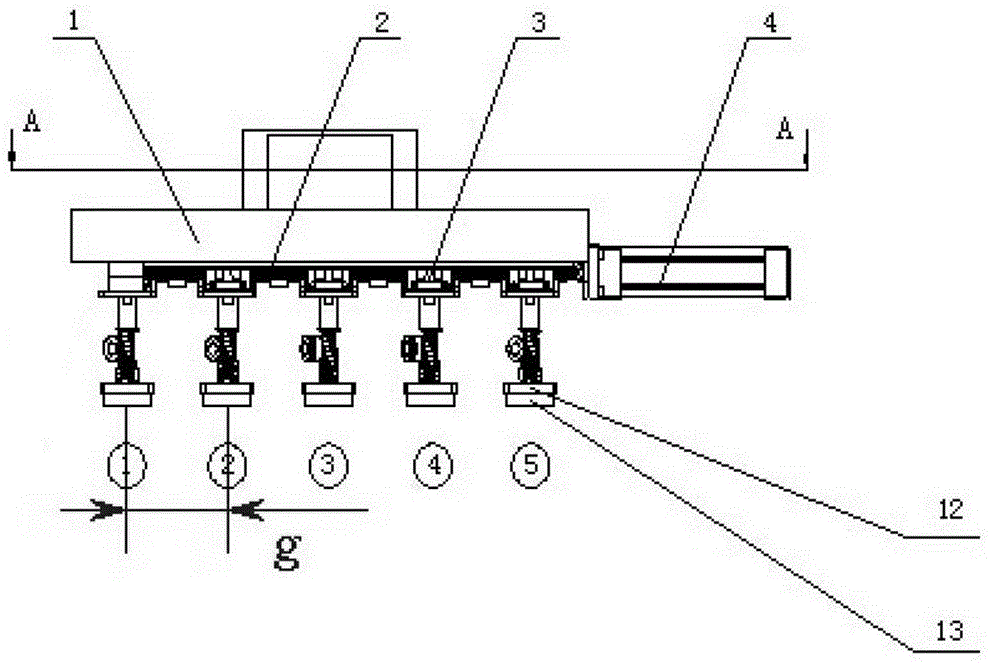

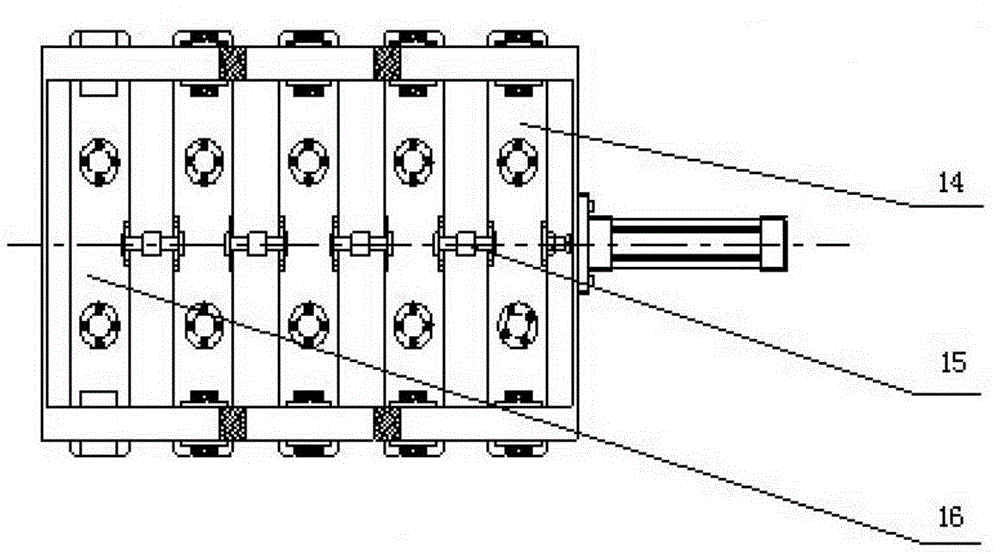

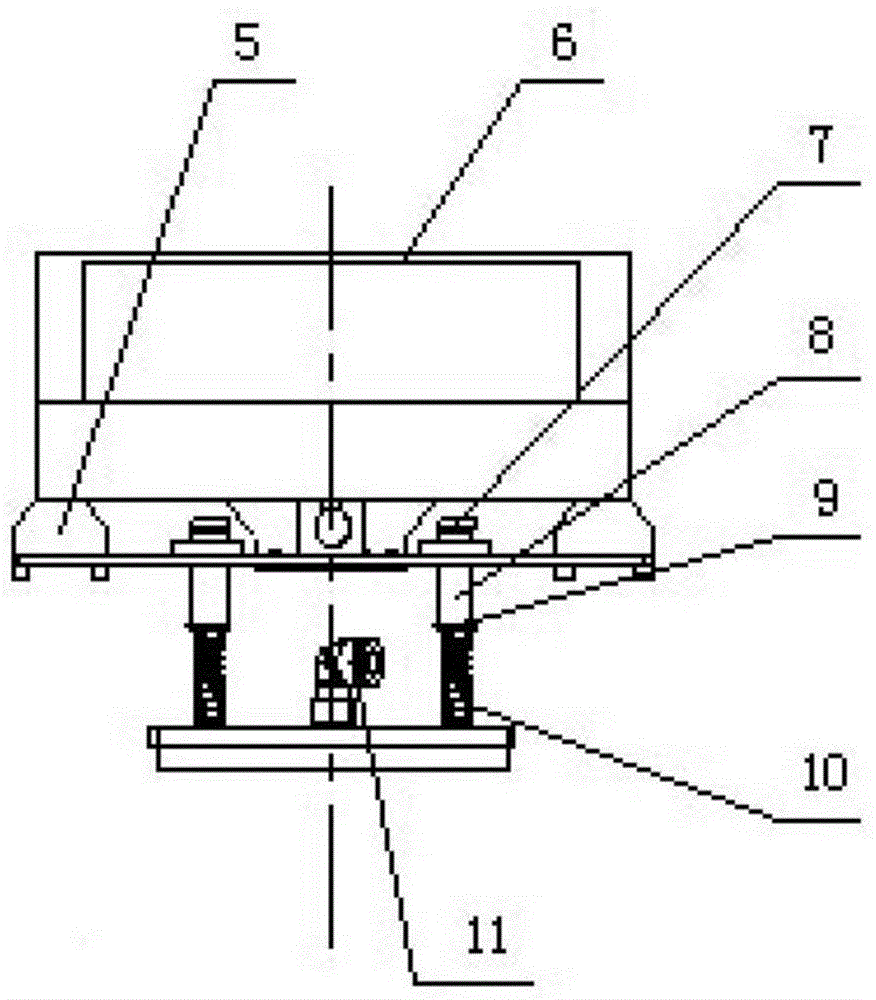

[0024] Such as Figure 1 to Figure 6 As shown, a kind of space-dividable sucker type stacking manipulator (abbreviated as manipulator) of the present invention includes guide rail support 1, linear guide rail 2, slider 3, drive cylinder 4, fixed block 5, flange connecting plate 6, guide shaft 7 , linear bearing 8, washer 9, buffer spring 10, vacuum joint 11, suction cup bottom plate 12, suction cup 13, mobile mounting plate 14, spacer shaft 15, fixed mounting plate 16; said rail bracket 1 is connected with a flange connecting plate 6 , the linear guide rail 2 is installed symmetrically on both sides below it; the slide block 3 is equipped with on the linear guide rail 2, and the slide block 3 is connected with the mobile mounting plate 14 by screws; the left end of the guide rail bracket 1 is equipped with a fixed block 5 , the fixed block 5 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com