A tunnel waterproof board, a welding method between waterproof boards, and a hot-melt welding machine

A tunnel waterproofing plate and welding method technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problem of affecting the uniformity of heating on the surface of the plate in the welding area, it is difficult to achieve the consistency of melting temperature at the same time, and destroy the strength of the material body, etc. problems, to achieve the effect of great economic value and social significance, excellent security functions, and guaranteed welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

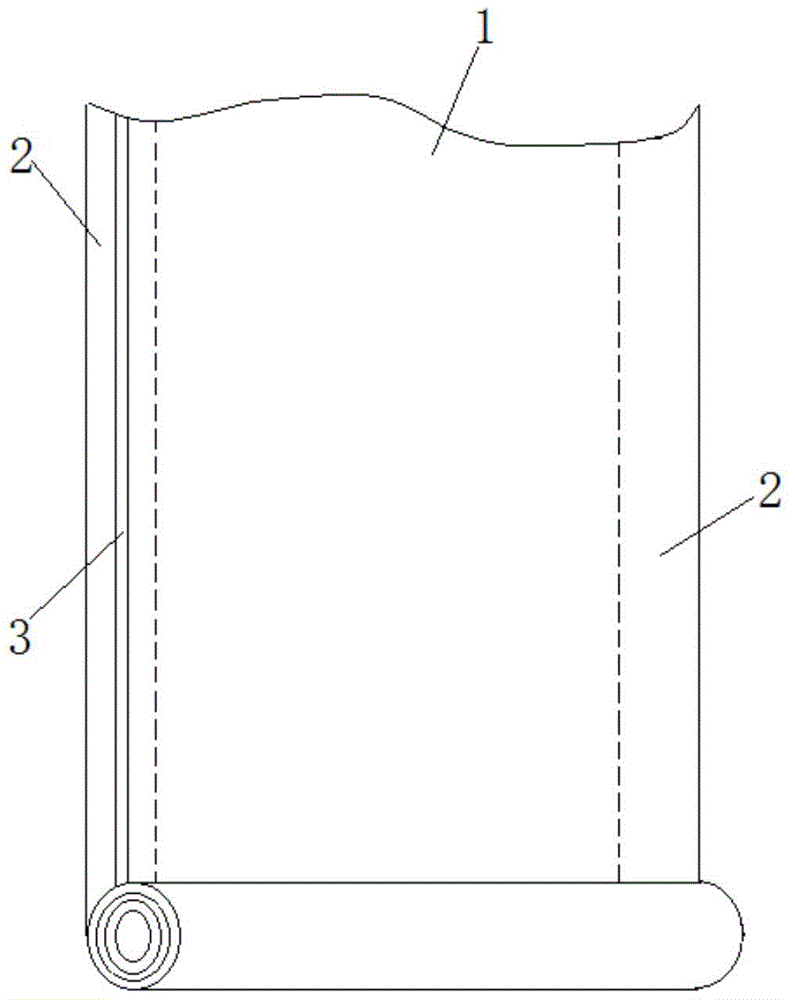

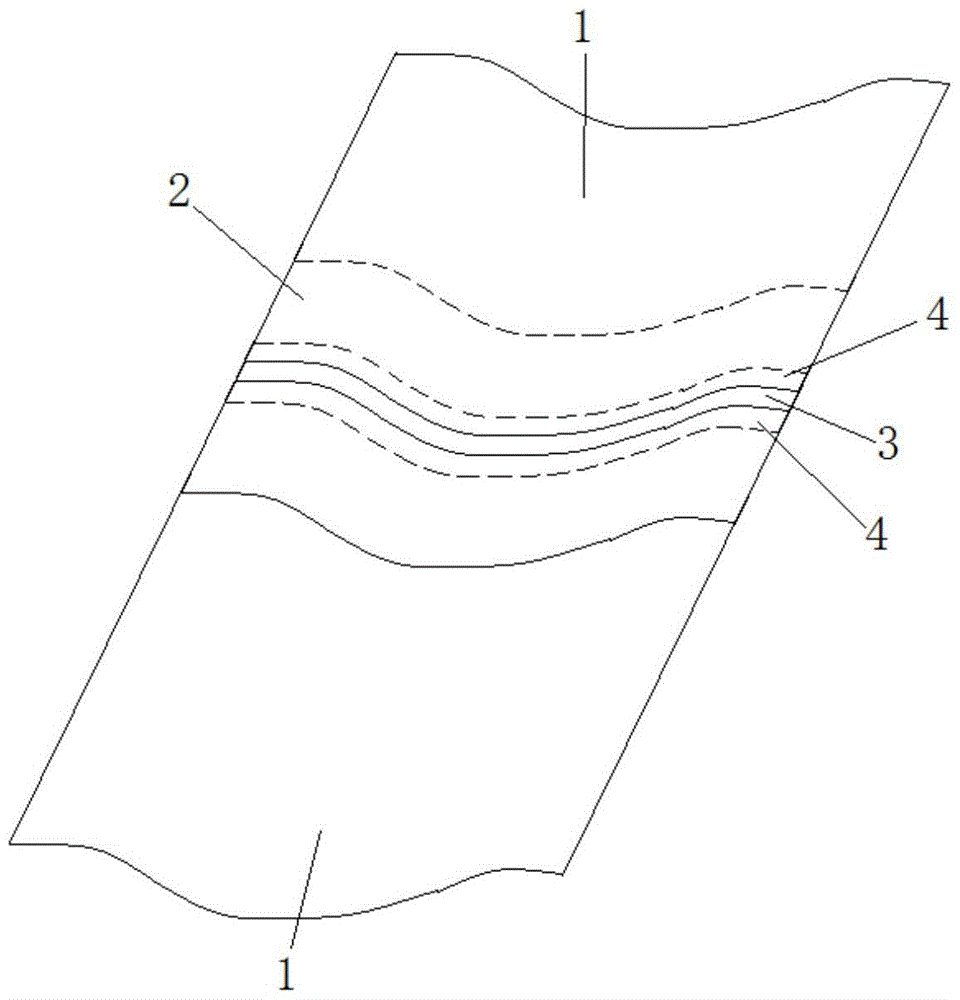

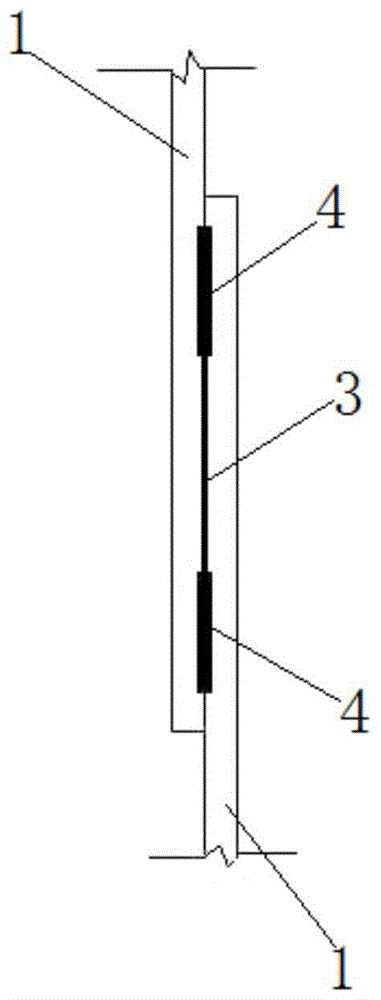

[0035] (1) Install the tunnel waterproof board, the tunnel waterproof board such as figure 1 As shown, its two sides are defined as inter-ring lapping areas 2 according to their functions, and the inter-ring lapping areas 2 of two adjacent waterproof boards 1 are superimposed together. In the overlapping area 2 between the rings of the waterproof board 1, the front and / or reverse side of the waterproof board 1 is provided with a fusion sealing welding belt 3, that is, the fusion sealing welding belt 3 can be arranged on the overlapping area 2 between the rings on either side, or at the same time In the overlapping areas 2 between the rings on both sides, the fusion sealing welding strip 3 can be arranged on either side (ie front or back) of the overlapping areas 2 between the rings, or can be arranged on both front and back sides of the overlapping areas 2 between the rings.

[0036] The fusion sealing welding zone 3 selects the red color that is different from the color of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com