Spraying type tabletting crusher

A crusher and spray technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of poor natural cooling effect of tablet compression, inability to compress tablet heat dissipation and solidification, and low efficiency of tablet crusher, so as to shorten the length, The effect of improving efficiency and increasing transportation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The detailed structure of the present invention will be further described below in conjunction with the drawings and specific embodiments.

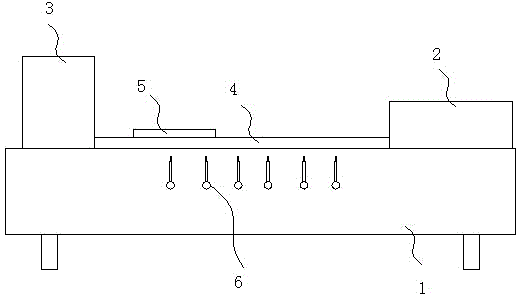

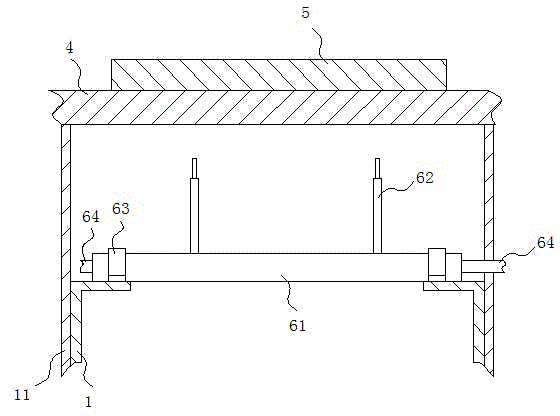

[0012] Such as figure 1 Shown: a tablet crusher, including a frame 1, the frame 1 is provided with a tablet mechanism 2, a crawler belt 4, and a crushing mechanism 3 in sequence, and the crawler mechanism 4 conveys the output tablet 5 of the tablet mechanism 2 to Crushing mechanism 3; such as figure 2 As shown, the outer periphery of the frame 1 is equipped with a steel plate 11 to form a closed structure, and a spray mechanism 6 is provided under the inner track 4 of the frame 1. The spray mechanism 6 includes a liquid inlet pipe 61 and is installed on the inlet The nozzle 62 on the liquid pipe 61, the liquid inlet pipe 61 is fixed on the frame 1 by a fixed block 63, the two ends of the liquid inlet pipe 61 are connected by a connecting pipe 64, and the connecting pipe 64 and the liquid inlet pipe 61 are connected to the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com