Multi-degree-of-freedom power shift parallel hybrid multi-speed transmission

A power shift and hybrid technology, applied in the field of power transmission, can solve problems such as affecting the power performance of the vehicle, difficult to realize the hybrid function, power interruption, etc., and achieve the effects of improving power performance, shortening shift time, and improving power density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

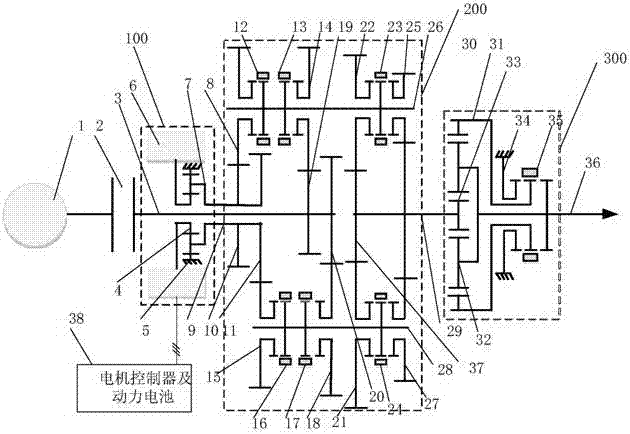

[0019] See attached figure 1 , a multi-degree-of-freedom power shift parallel hybrid multi-speed gearbox, which includes: an engine 1, a clutch 2, a motor module 100, a gearbox main box module 200 and a gearbox auxiliary box module 300;

[0020] The clutch is located between the engine 1 and the motor module 100;

[0021] The motor module 100 includes: a motor 6 and a deceleration planetary row; the motor 6 is coaxially arranged with the engine input shaft 3, and the motor 6 is connected to the sun gear 4 of the deceleration planetary row on the one hand, and the other is conveniently connected to the motor controller and the power battery 38; the deceleration planetary The ring gear 5 of the row is fixed, and the planet carrier 7 of the deceleration planetary row is connected to the motor power input shaft 9;

[0022] The gearbox main box module 200 adopts a five-shaft arrangement and includes six synchronizers; wherein, the gearbox main box output shaft 29 is coaxially arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com