An eight-speed dual-clutch transmission

A dual clutch and transmission technology, applied in the field of vehicle transmission, can solve the problems of inability to arrange and increase the volume and weight, and achieve the effects of increasing fuel economy, compact structure and satisfying light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

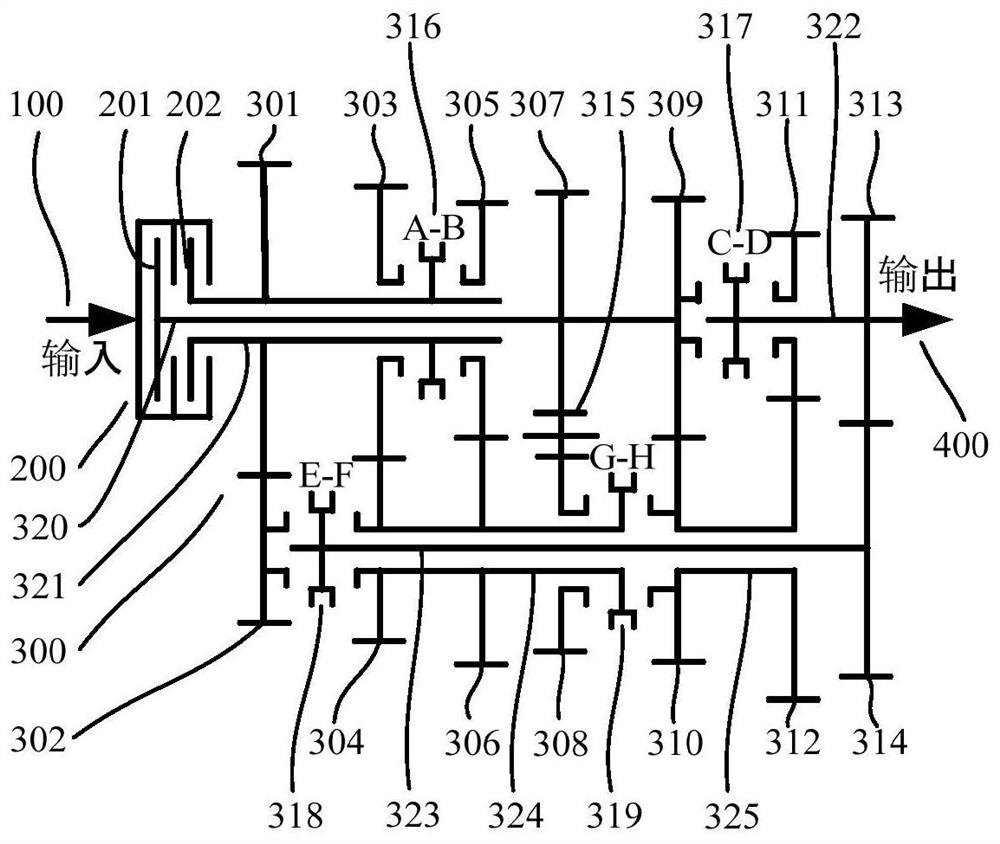

[0052] like Figure 1-10 As shown, the present invention provides an eight-speed dual-clutch transmission. Through the reasonable arrangement of gears and synchronizers, the transmission has a compact structure, the reusability of the gear mechanism is improved, and the design requirements of light weight and compactness can be met.

[0053] See attached figure 1 , the dual clutch transmission includes: an engine input end 100 , a clutch module 200 , a transmission module 300 , and an output end 400 .

[0054] The clutch module 200 includes: a first clutch 201 and a second clutch 202;

[0055] The transmission module 300 includes: a first gear 301, a second gear 302, a third gear 303, a fourth gear 304, a fifth gear 305, a sixth gear 306, a seventh gear 307, an eighth gear 308, and a ninth gear 309, tenth gear 310, eleventh gear 311, twelfth gear 312, thirteenth gear 313, fourteenth gear 314, idler gear 315, first synchronizer 316, second synchronizer 317, third synchronizer...

Embodiment 2

[0060] The eight-speed dual-clutch transmission has eight forward gears and one reverse, as follows:

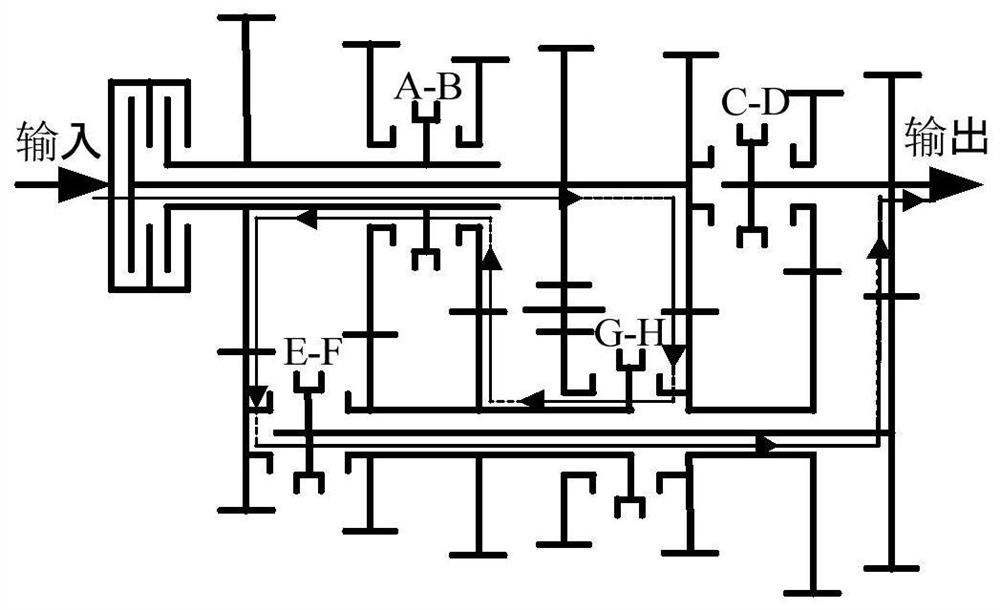

[0061] see figure 2 , when the eight-speed dual-clutch transmission is in the first gear state, the first synchronizer 316, the third synchronizer 318 and the fourth synchronizer 319 work, the first synchronizer 316 engages to the right, and the third synchronizer 318 engages to the left, The fourth synchronizer 319 meshes to the right. After the engine power is input to the transmission module 300 through the engine input end 100 through the first clutch 201 and the first input shaft 320, it passes through the ninth gear 309, the tenth gear 310, and the fourth synchronizer in sequence. 319, the first intermediate shaft sleeve shaft 324, the sixth gear 306, the fifth gear 305, the first synchronizer 316, the second input shaft 321, the first gear 301, the second gear 302, the third synchronizer 318, the middle The shaft 323 , the fourteenth gear 314 and the thirteenth gear ...

Embodiment 3

[0075] Introduce the power shift process of the transmission:

[0076] Shift process from 1st to 2nd gear:

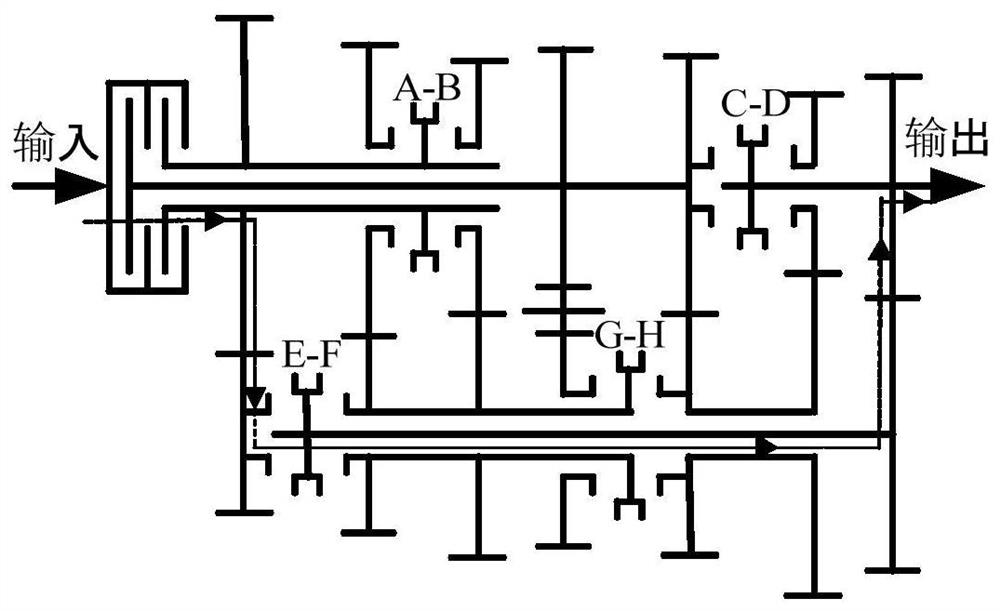

[0077] Before shifting, the transmission is in gear 1, the first clutch 201 is engaged, the first synchronizer 316 is engaged to the right, the third synchronizer 318 is engaged to the left, and the fourth synchronizer 319 is engaged to the right. The power flow is as follows: figure 2 shown. When shifting gears, there is no need to operate the synchronizer; during the shifting process, the first clutch 201 is disengaged, and the second clutch 202 is combined; The device 318 continues to work, the engine outputs power, and its power flow is as follows: image 3 shown.

[0078] 2nd gear to 3rd gear shifting process:

[0079] Before shifting, the transmission is in the 2nd gear state, the second clutch 202 is combined, and the third synchronizer 318 is engaged to the left, and its power flow is as follows: image 3 As shown; when shifting gears, pre-engage the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com