Airframe butt joint attitude-adjusting method meeting stringer reference alignment and straightness requirements

A technology for aircraft fuselage and straightness, which is applied in aircraft assembly, aircraft parts, ground installations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

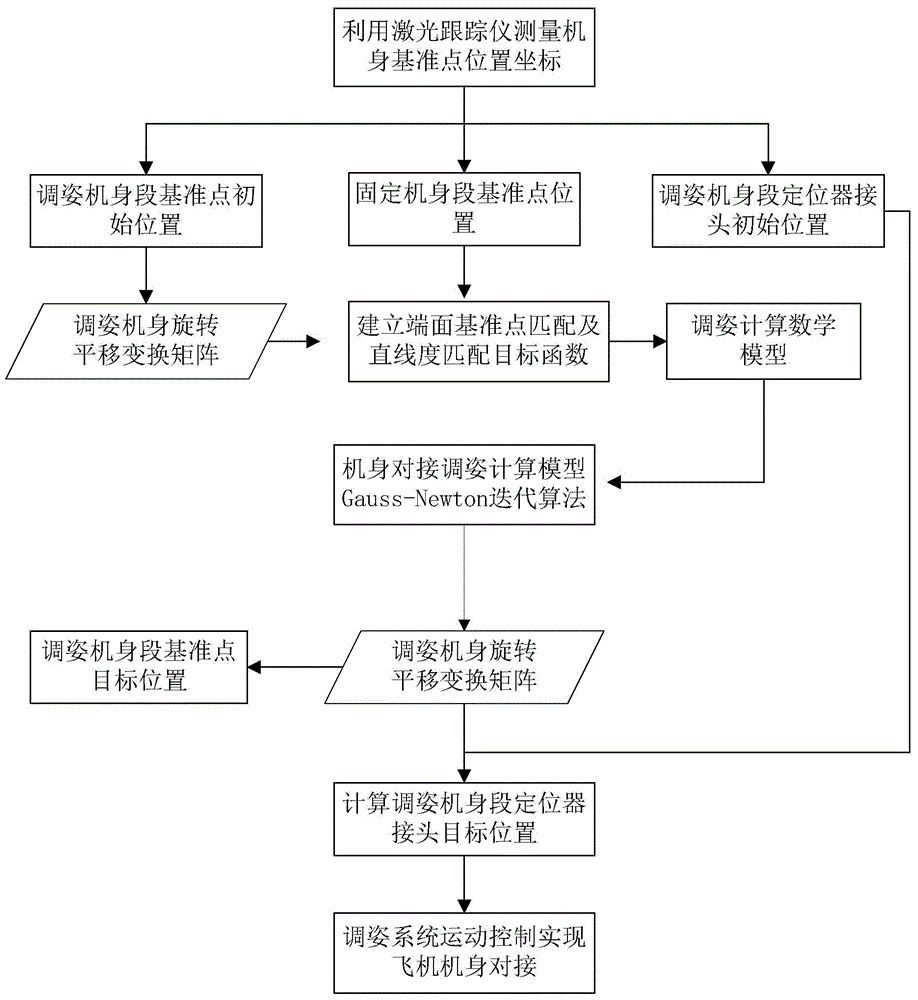

[0021] The implementation of the method of the present invention will be described in detail below in conjunction with the accompanying drawings. The flow chart of the method is as figure 1 shown.

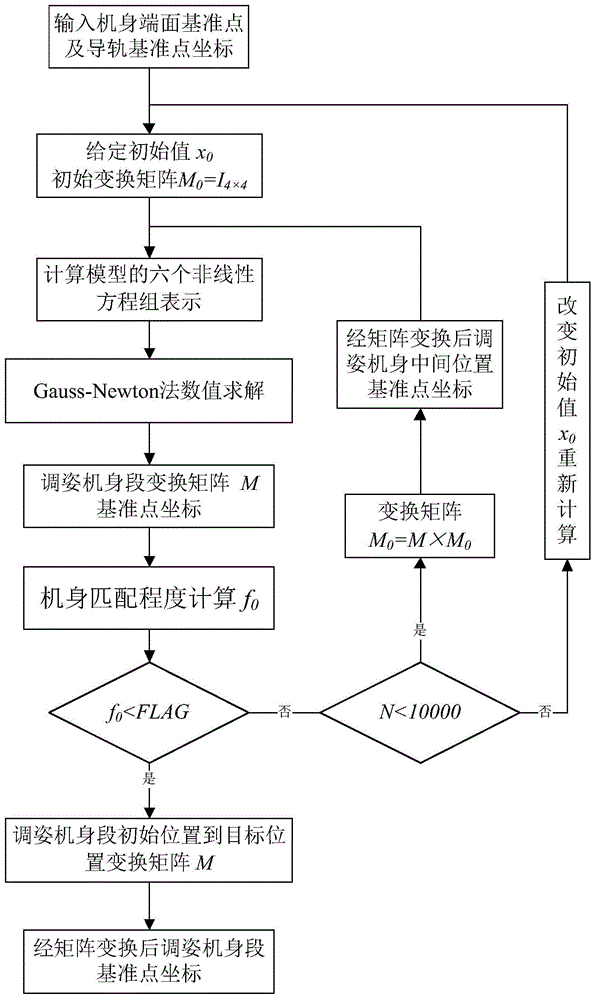

[0022] Invention of this aircraft fuselage docking attitude adjustment method considering reference point alignment and straightness requirements is characterized in that (1) the method uses the least squares method to establish two-section docking fuselage end surface reference point matching and fuselage straightness matching objective functions ; (2) Gauss-Newton method is used to iteratively calculate the aircraft fuselage docking attitude adjustment model; (3) the three-coordinate locator joint of the attitude adjustment system connected to the attitude adjustment fuselage section is controlled from the initial position coordinates to the target position coordinates The method of realizing the optimal matching and docking of the attitude-adjusting fuselage section and the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com