Self-pressurization space spraying equipment

A spraying equipment, self-pressurization technology, applied in the directions of space navigation equipment, tools, transportation and packaging, to achieve the effect of simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The function of the spraying equipment of the present invention is to carry a certain amount of liquid material. After receiving the detonation electric signal to start working, the liquid material is sprayed out from the inside of the spraying equipment according to the required speed, diffusion angle, and flow rate, and sprayed to the star table equipment. .

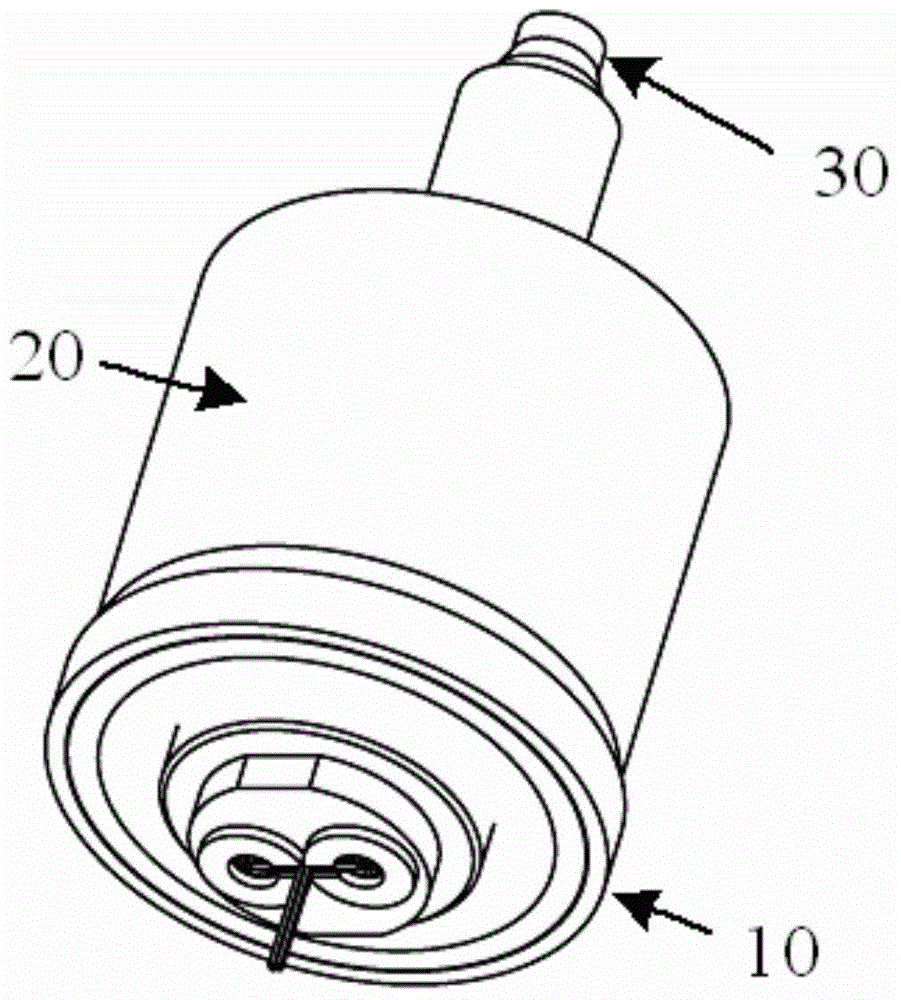

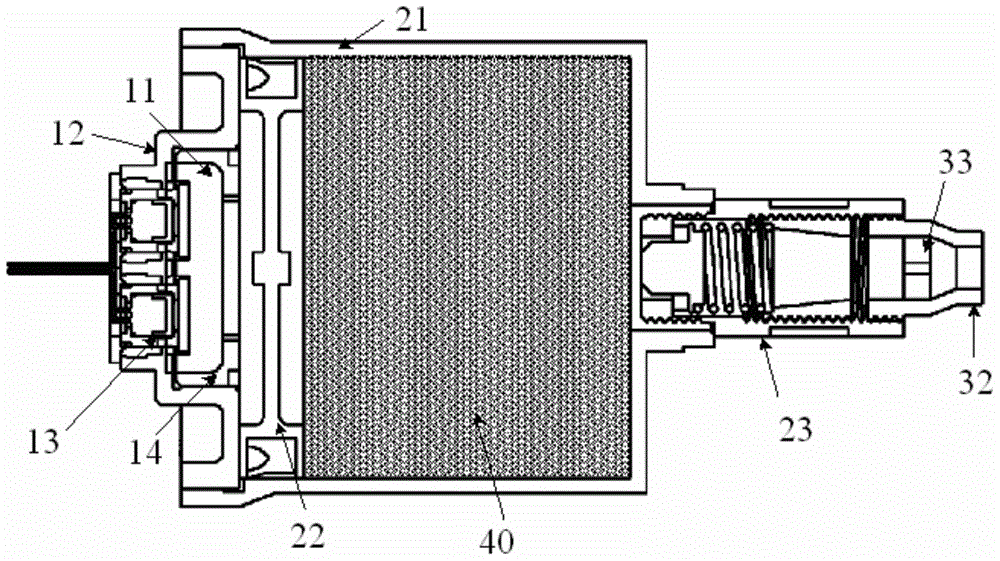

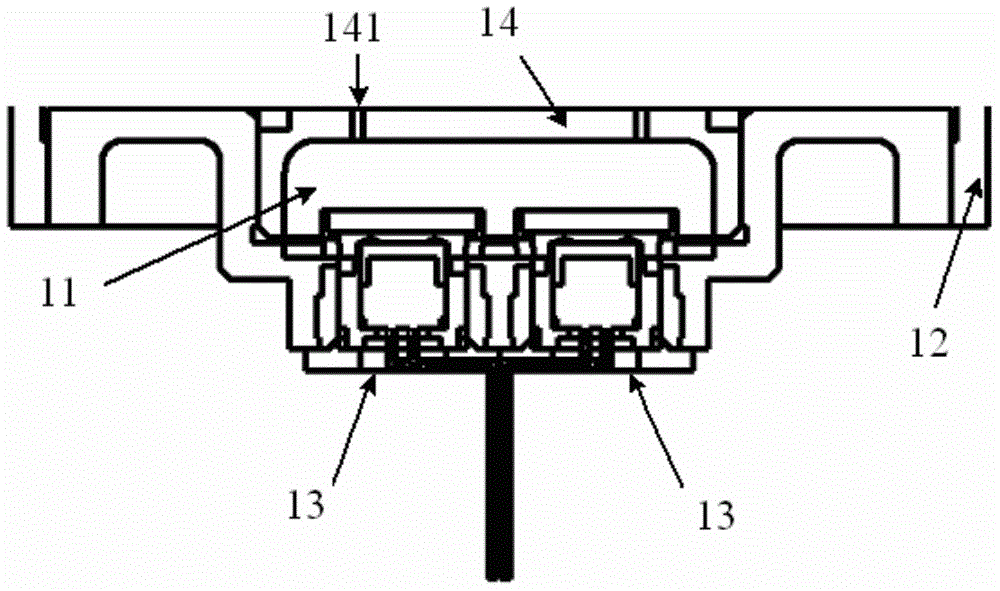

[0034] The overall external configuration of the spraying equipment of the present invention is as attached figure 1 As shown, the liquid spraying equipment of the present invention is composed of three parts: a gas generating source 10 , a driving assembly 20 and a spraying assembly 30 .

[0035] see figure 2 As shown, the liquid material 40 is the working fluid for improving the performance of the star surface equipment, which is stored inside the cavity structure 21 of the liquid drive assembly 20, and is sprayed from the equipment to the star surface during the working process of the spray coating equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com