A suction structure for pipe feeding

A catheter and guide rail technology, which is applied to conveyor objects, transportation and packaging, etc., can solve problems such as catheter deformation, and achieve the effects of preventing deformation under pressure, reliably sucking, and avoiding rigid pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

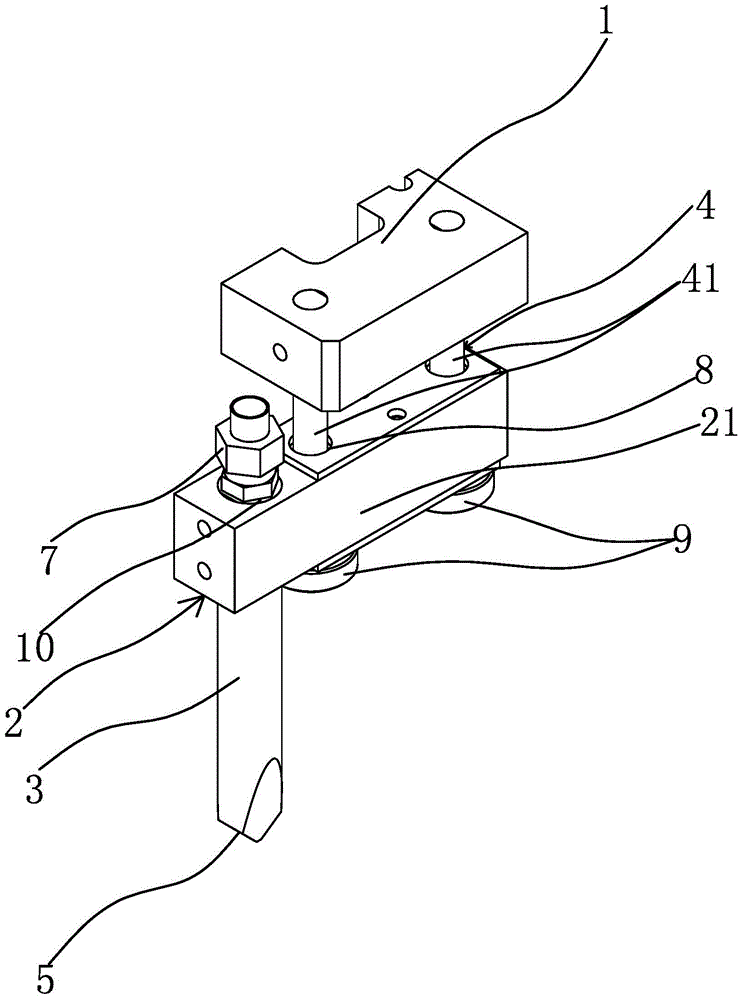

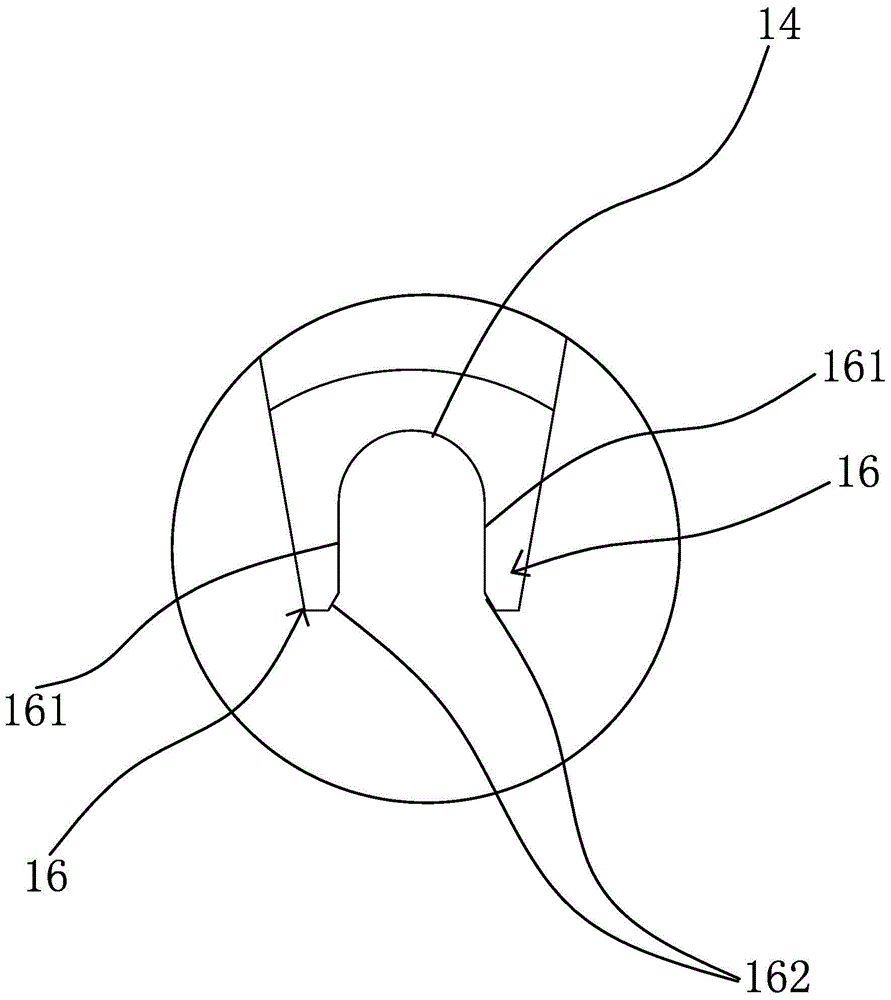

[0032] like Figure 1 to Figure 6As shown, the suction structure adopts the suction method to take and move the components of the catheter of the infusion set, so as to avoid the direct mechanical contact pressure pressing the catheter to deform it when the catheter is clamped. The suction structure in this embodiment includes a mounting seat 1 and a gas cylinder. The claw lever 3 is provided with a sliding mechanism 4 between the mounting base 1 and the air claw lever 3 which can make the air claw lever 3 slide up and down in the vertical direction. The lower end of 3 has an arc-shaped concave claw 5, and the air claw rod 3 has a ventilation hole 6 that communicates with the claw 5. The claw 5 is composed of two symmetrical claw pieces 16, and the outer side of the claw piece 16 is Inclined surface 15 sloping from outside to inside.

[0033] like figure 1 and figure 2 As shown, the counterweight structure 2 is a counterweight block 21, the sliding mechanism 4 includes a v...

Embodiment 2

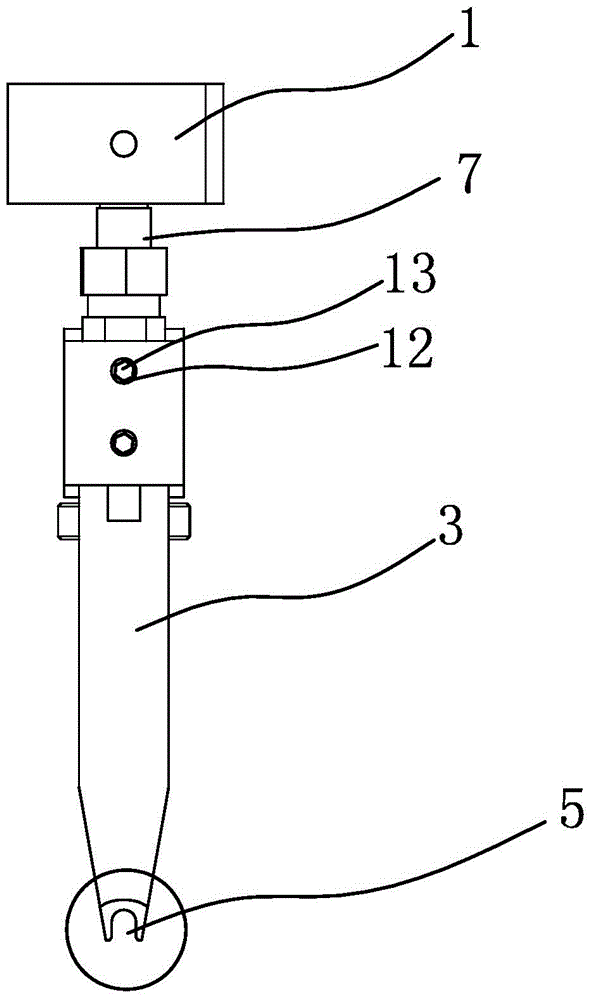

[0037] like Figure 7 As shown, this embodiment is roughly the same as the first embodiment, the difference lies in that, as another kind of counterweight structure 2 in this embodiment, the counterweight structure 2 is a section on the air gripper rod 3, and the sliding mechanism 4 includes a The guide hole 44 on the mounting base 1, the air gripper rod 3 is arranged in the guide hole 44 and is slidably connected with the guide hole 44, and the counterweight structure 2 is used as a section on the air gripper rod 3, which simplifies the structure. The force of the rod 3 is more stable and even, which is convenient for separating the accumulated conduits.

Embodiment 3

[0039] like Figure 8 As shown, this embodiment is roughly the same as the first embodiment, the difference is that, as another guide rail structure in this embodiment, the guide rail is a rail 42 fixed on the side wall of the mounting seat 1, and the side wall of the counterweight block is provided with a rail 42. There are guide grooves 43, the rails 41 are arranged in the corresponding guide grooves 43, and the up and down sliding of the air gripper rod 3 is realized through the cooperation of the guide grooves 43 and the rails 42. Such cooperation makes the position of the air gripper rod 3 stable, without shaking and turn. Of course, the positions of the guide groove 43 and the rail 42 can be interchanged, that is, the guide groove 43 is provided on the side wall of the mounting base 1 , and the rail 42 is provided on the side wall of the counterweight block 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com