A kind of water dispersion paint prepared with pet waste and soybean oil acid

A technology of dispersion and soybean oil, which is applied in the direction of coating, etc., to achieve the effect of improving the hydrolysis stability of ester bonds, reducing pollution and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

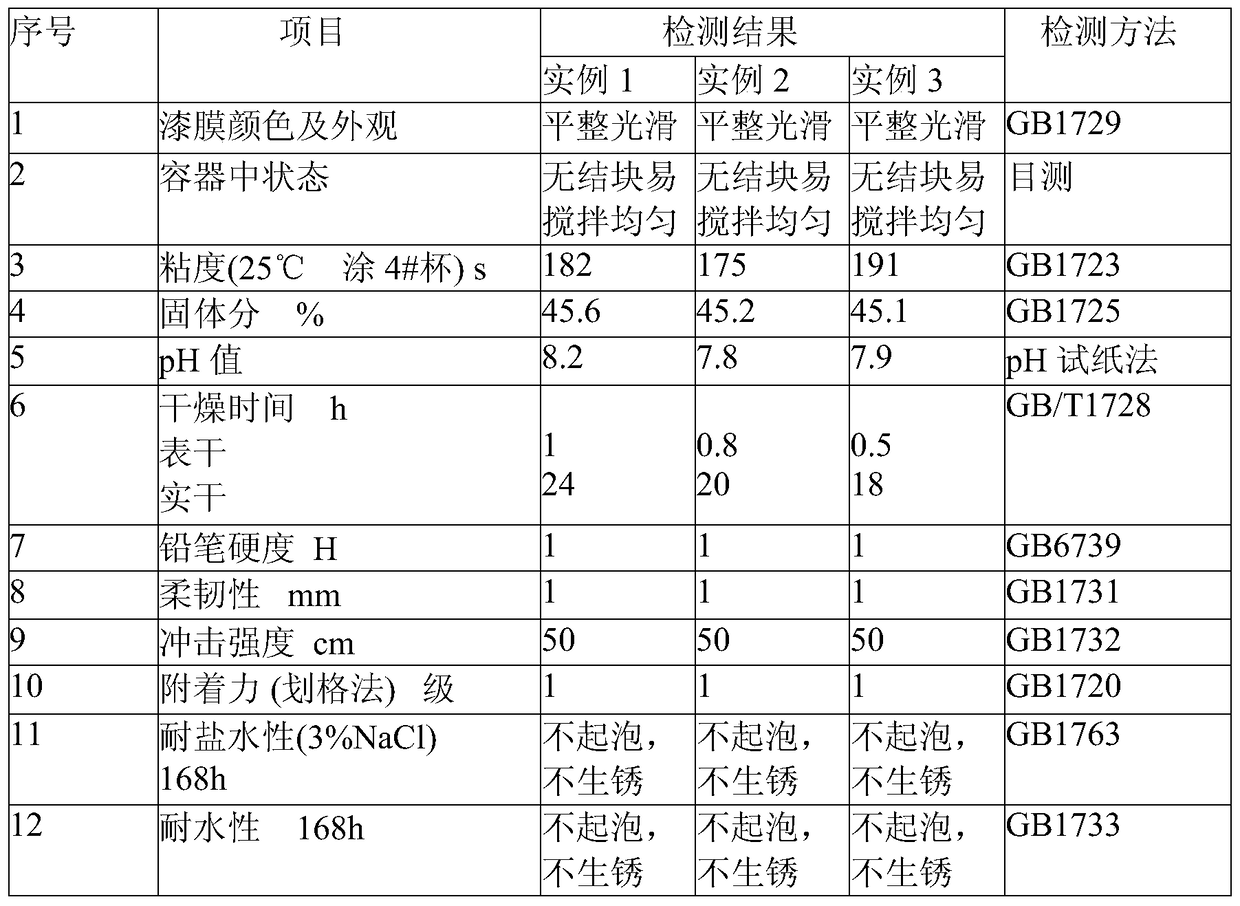

Embodiment 1

[0024] ①Put 140 grams of polyester PET waste or waste polyester PET bottles (cut into small pieces of about 1 square centimeter), 7.5 grams of ethylene glycol, 26 grams of trimethylolpropane, 37 grams of glycerin, and 0.03 grams of zinc acetate into the container In the four-necked reaction flask with thermometer, stirrer, reflux condenser and inert gas inlet, raise the temperature to 180°C until most of the material melts, start stirring, and perform degradation reaction at 200-250°C for 3-4 hours until the softening point drops to 35 At -45°C, distill free alcohol under reduced pressure, then add 102 grams of soy oleic acid, 7.0 grams of phthalic anhydride, and 7.0 grams of partial anhydride to carry out esterification reaction at 170°C. When the acid value is 15-20㎎KOH / g, cool down to A mixed solution of 16 grams of acrylic acid, 26 grams of methyl methacrylate and 1.6 grams of benzoyl peroxide was added dropwise at 110°C. After 2 hours of dripping, the reaction was carried...

Embodiment 2

[0027] ① Put 140 grams of polyester PET waste or waste polyester PET bottles (cut into small pieces of about 1 square centimeter), 17.5 grams of ethylene glycol, 36 grams of neopentyl glycol, 17 grams of glycerin, and 0.03 grams of zinc acetate into a thermometer equipped with , stirrer, reflux condenser, and a four-necked reaction flask with inert gas inlet, raise the temperature to 180°C until most of the material melts, start stirring, and perform a degradation reaction at 200-250°C for 3-4 hours until the softening point drops to 35- At 45°C, distill the free alcohol under reduced pressure, then add 95 grams of soy oleic acid, 14.0 grams of phthalic anhydride, and 7.0 grams of glycidyl tert-carbonate for esterification reaction at 170°C. When the acid value is 15-20㎎KOH / g, The temperature was lowered to 110° C. and a mixed solution of 16 grams of acrylic acid, 26 grams of styrene and 1.6 grams of benzoyl peroxide was added dropwise. After 2 hours of dripping, the reaction wa...

Embodiment 3

[0030] ① 140 grams of polyester PET waste or waste polyester PET bottle (cut into small pieces of about 1 square centimeter), 12.5 grams of ethylene glycol, 19 grams of neopentyl glycol, 26 grams of trimethylolpropane, 13 grams of glycerin, Put 0.03 grams of zinc acetate into a four-necked reaction flask equipped with a thermometer, agitator, reflux condenser and inert gas inlet, raise the temperature to 180°C until most of the material melts, start stirring, and carry out the degradation reaction at 200-250°C for 3-4 hours , when the softening point drops to 35-45°C, distill the free alcohol under reduced pressure, then add 102 grams of soybean oil, 7.0 grams of maleic anhydride, and 7.0 grams of partial anhydride to carry out esterification reaction at 170°C, and the acid value is 15 -20㎎KOH / g, lower the temperature to 110°C and add dropwise a mixed solution of 16 grams of methacrylic acid, 16 grams of styrene, 10 grams of butyl acrylate and 1.6 grams of benzoyl peroxide. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com