Continuous annealing method for cool-rolled thick high strength steel plates

A high-strength steel plate and thick-gauge technology, applied in the field of ferrous metal processing, can solve the problems of inconsistent parts size, large forming springback, and unfavorable safety of structural parts, achieving good product consistency, good production controllability, and implementation. less difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

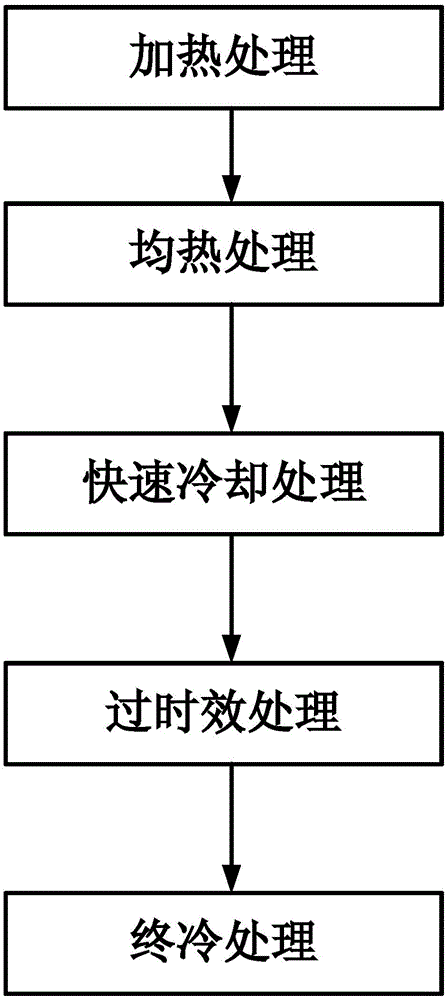

Method used

Image

Examples

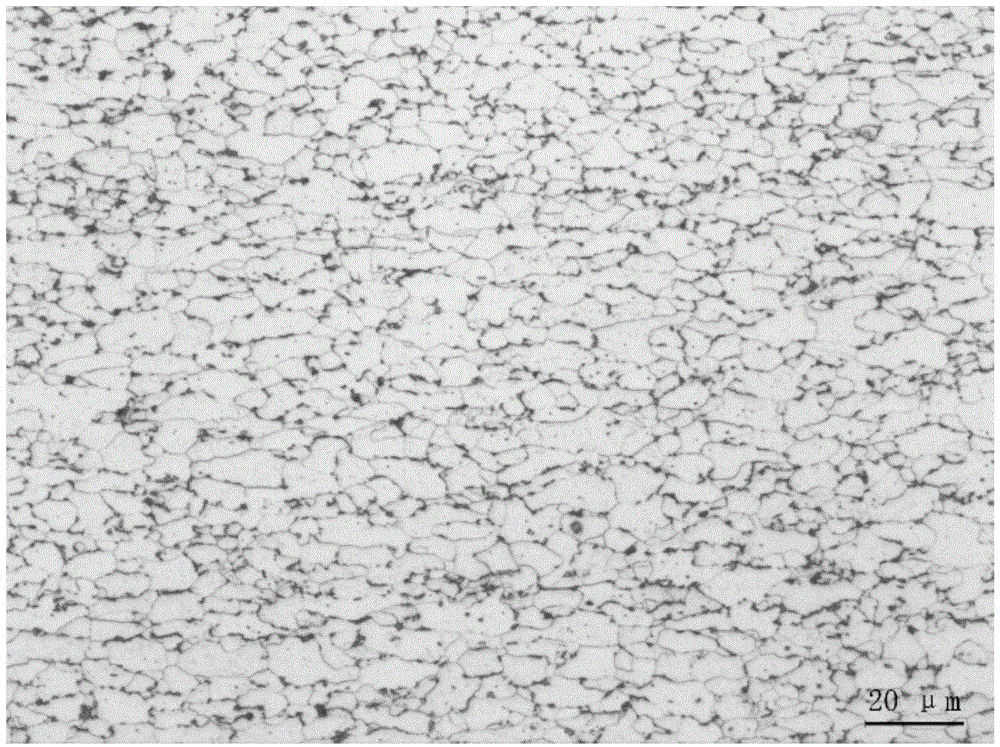

Embodiment 1

[0044] The chemical composition of the steel plate of this embodiment is C content 0.06wt%, Si content 0.01wt%, Mn content 0.50wt%, P content 0.005wt%, S content 0.005wt%, Nb content 0.015wt%, Als content 0.001wt% , Fe balance. The cleaned and dried cold-rolled thick-gauge high-strength steel plate is placed in the heating treatment section of the galvanizing / continuous annealing dual-purpose unit, and the furnace temperature in the heating treatment section is raised to 720°C after 20 seconds; The steel plate is sent to the soaking treatment section with a furnace temperature of 770°C, and the soaking treatment lasts for 30 seconds; after the soaking treatment is completed, the steel plate is transferred to the rapid cooling treatment section with a steel plate moving device, and the temperature of the steel plate is cooled to 250°C in 10 seconds; After the rapid cooling treatment is completed, use the steel plate moving device to transfer the steel plate to the overaging tre...

Embodiment 2

[0046] The chemical composition of the steel plate of this embodiment is C content 0.12wt%, Si content 0.10wt%, Mn content 1.2wt%, P content 0.025wt%, S content 0.020wt%, Nb content 0.050wt%, Als content 0.08wt% , Fe balance. The cleaned and dried cold-rolled thick-gauge high-strength steel plate is placed in the heating treatment section of the galvanizing / continuous annealing dual-purpose unit, and the furnace temperature in the heating treatment section is raised to 745°C after 90 seconds; The steel plate is sent to the soaking treatment section with a furnace temperature of 790°C, and the soaking treatment lasts for 60 seconds; after the soaking treatment is completed, the steel plate is transferred to the rapid cooling treatment section with a steel plate moving device, and the temperature of the steel plate is cooled to 300°C in 60 seconds; After the rapid cooling treatment is completed, use the steel plate moving device to transfer the steel plate to the overaging treat...

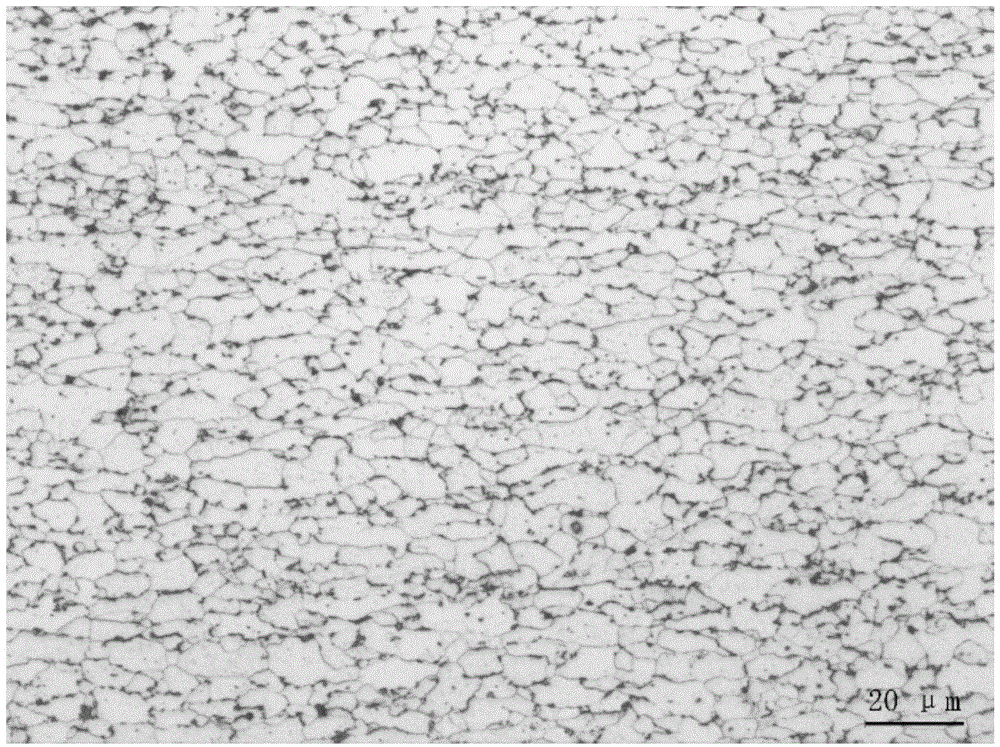

Embodiment 3

[0048] The chemical composition of the steel plate of this embodiment is C content 0.08wt%, Si content 0.07wt%, Mn content 0.7wt%, P content 0.015wt%, S content 0.010wt%, Nb content 0.030wt%, Als content 0.04wt% , Fe balance. The cleaned and dried cold-rolled thick-gauge high-strength steel plate is placed in the heating treatment section of the galvanizing / continuous annealing dual-purpose unit, and the furnace temperature in the heating treatment section is raised to 730°C after 70 seconds; The steel plate is sent to the soaking treatment section with a furnace temperature of 780°C, and the soaking treatment lasts for 50 seconds; after the soaking treatment is completed, the steel plate is transferred to the rapid cooling treatment section with a steel plate moving device, and the temperature of the steel plate is cooled to 280°C in 45 seconds; After the rapid cooling treatment is completed, use the steel plate moving device to transfer the steel plate to the overaging treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com