Temperature-sensitive low ignition propensity cigarette paper, and preparation method thereof

A low-ignition tendency, cigarette paper technology, applied in special paper, paper, papermaking, etc., can solve the problems of easy extinguishment and decline in cigarette smoking quality, and achieve the effect of high moisture content and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] a. Weigh the temperature-sensitive material Loxamer 407: Poloxamer 188 according to the mass ratio of 7:3, and put it in water (water: temperature-sensitive material mass ratio 6:6), stir well, and place in 24 hours at 0°C until completely dissolved to form an aqueous solution;

[0028] b. Add calcium carbonate (temperature-sensitive material: calcium carbonate mass ratio 2:6) to the aqueous solution of step a and stir evenly to form a temperature-sensitive composite material, and place it at room temperature for subsequent use;

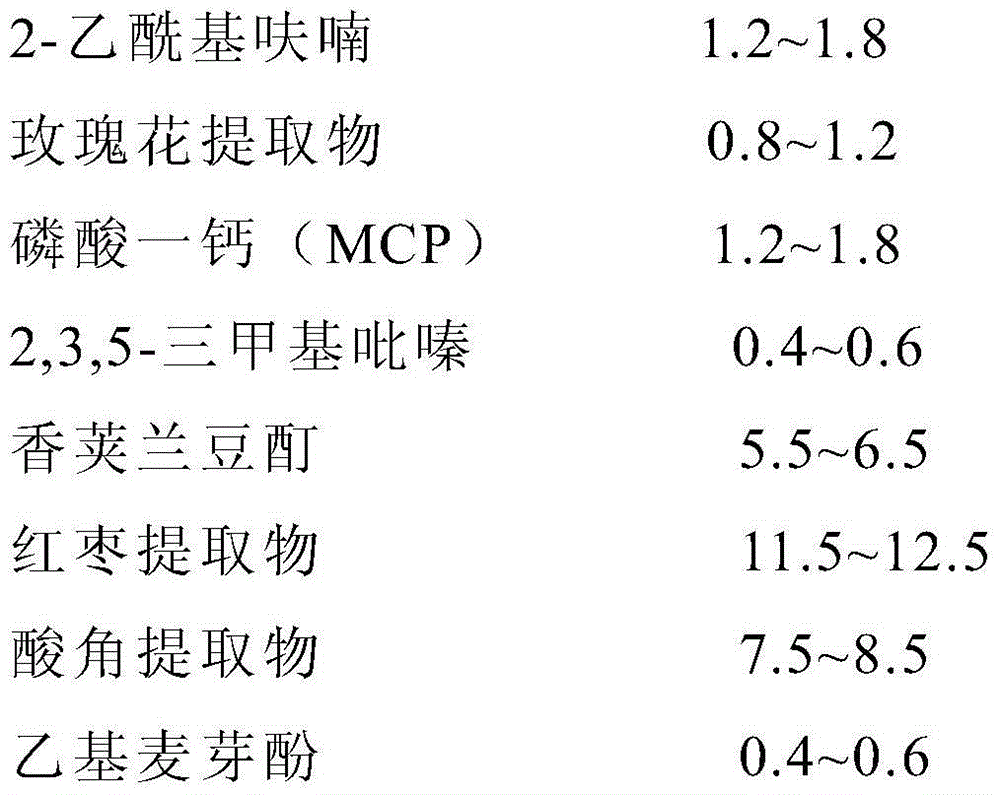

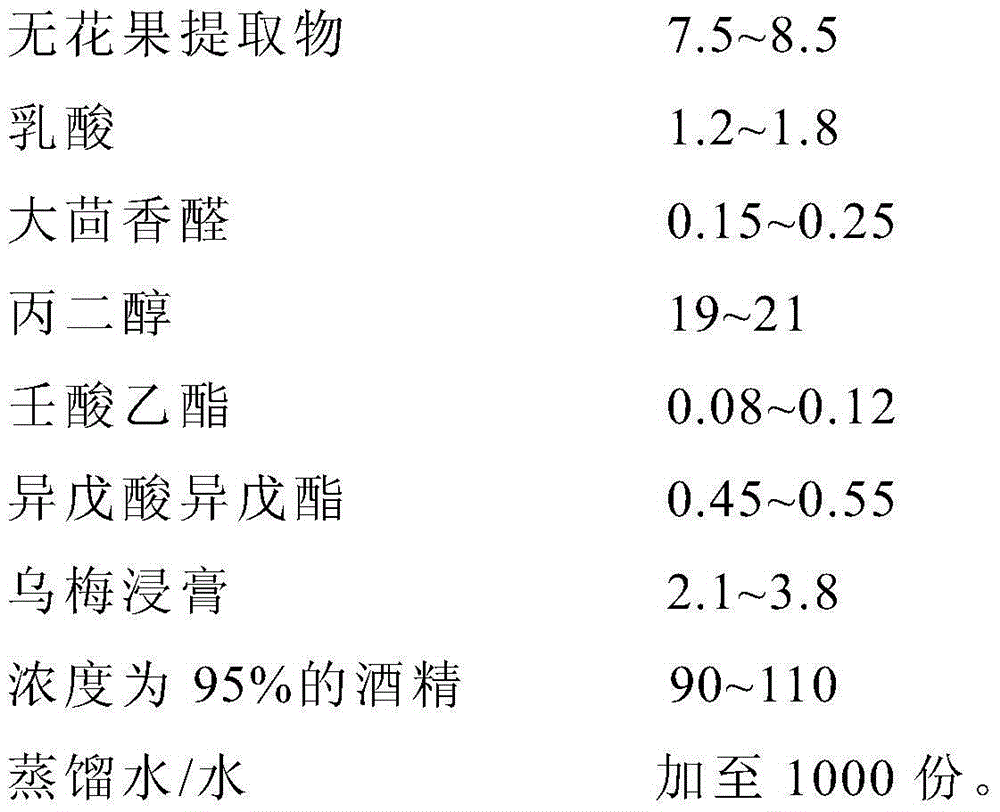

[0029] c. The essence formula is as shown in Table 1:

[0030] Table 1 Flavor formulations for cigarette papers with low ignition tendency

[0031]

[0032]

[0033] d. Mix the temperature-sensitive composite material and essence prepared in step b and step c in a mass ratio of 9.2:0.8, stir evenly at a temperature of 5°C, and place it at room temperature for 12 hours until it becomes a solid material for later use ;

[0034] e. Choos...

Embodiment 2

[0036] a. Weigh the temperature-sensitive material Loxamer 407: Poloxamer 188 according to the mass ratio of 8:2, and put it in water (water: temperature-sensitive material mass ratio 12:6), stir well, and place 12 hours at 2°C until completely dissolved to form an aqueous solution;

[0037] b. Add calcium carbonate (temperature-sensitive material: calcium carbonate mass ratio 6:5) to the aqueous solution of step a and stir evenly to form a temperature-sensitive composite material, and place it at room temperature for subsequent use;

[0038] c. The essence formula is as shown in Table 2:

[0039] Table 2 Flavor formulations for cigarette papers with low ignition tendency

[0040]

[0041] d. Mix the temperature-sensitive composite material and essence prepared in step b and step c in a mass ratio of 9:1, and stir evenly at a temperature of 2°C, and place it at room temperature for 20 hours until it becomes a solid material for later use ;

[0042] e. Choose ordinary cig...

Embodiment 3

[0044]a. Weigh the temperature-sensitive material Loxamer 407: Poloxamer 188 according to the mass ratio of 8:2, and put it in water (water: temperature-sensitive material mass ratio 15:6), stir well, and place 12 hours at a temperature of 5°C until completely dissolved to form an aqueous solution;

[0045] b. Add calcium carbonate (temperature-sensitive material: calcium carbonate mass ratio 8:3) to the aqueous solution of step a and stir evenly to form a temperature-sensitive composite material, and place it at room temperature for subsequent use;

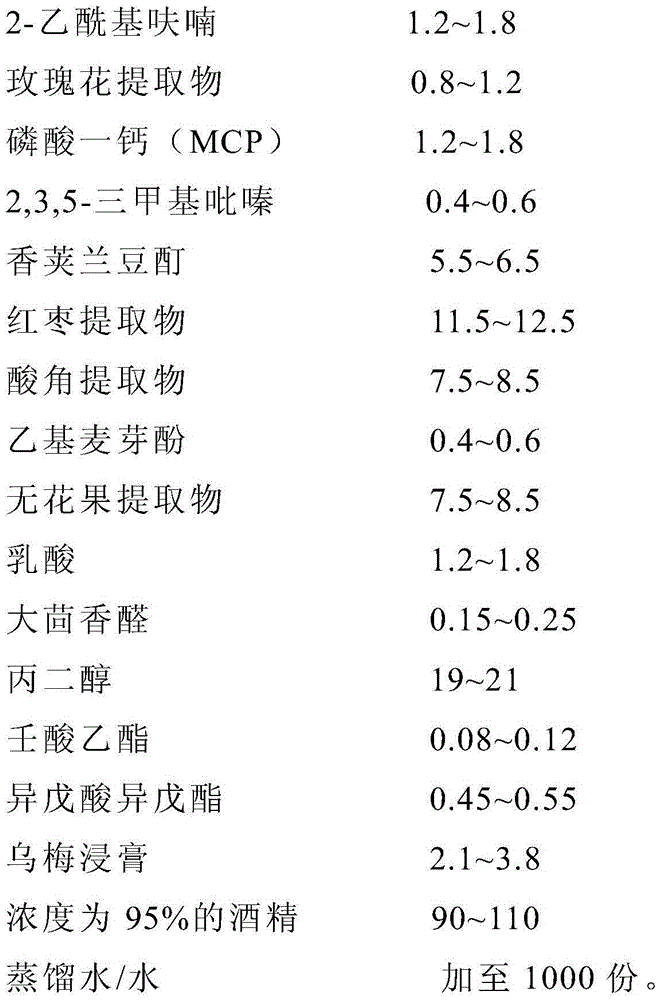

[0046] c. The essence formula is as shown in Table 3:

[0047] Table 3 Flavor formulations for cigarette papers with low ignition tendency

[0048]

[0049]

[0050] d. Mix the temperature-sensitive composite material and essence prepared in step b and step c at a mass ratio of 9.5:0.5, stir evenly at a temperature of 0°C, and place it at room temperature for 24 hours until it becomes a solid material for later use ;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com