A combined self-locking variable-diameter rubber plug

A self-locking, rubber plug technology, used in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problems of casing sealing performance and anti-wear performance not being guaranteed, affecting later operations, etc. , to meet the requirements of reducing diameter, improve compression performance and anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

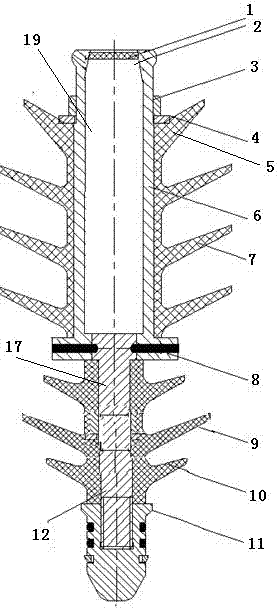

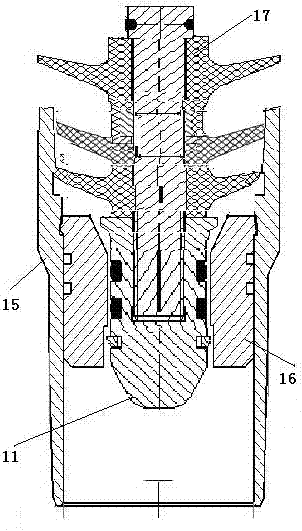

[0021] Such as figure 1 As shown, the present invention provides a combined self-locking variable-diameter rubber plug, including a lower rubber plug 17, the front end of the lower rubber plug 17 is connected with a self-locking head 11, and the rear end is connected with a glue upper end through a shear pin 8 Plug 19, the tail of the upper rubber plug 19 is provided with a tapered opening 2, and the tapered opening 2 is provided with a pressure-bearing elastic element 1 for isolating the inner cavity of the lower rubber plug 17 from the external liquid. The lower rubber plug 17 The outer diameter is less than the outer diameter of the rubber plug 19.

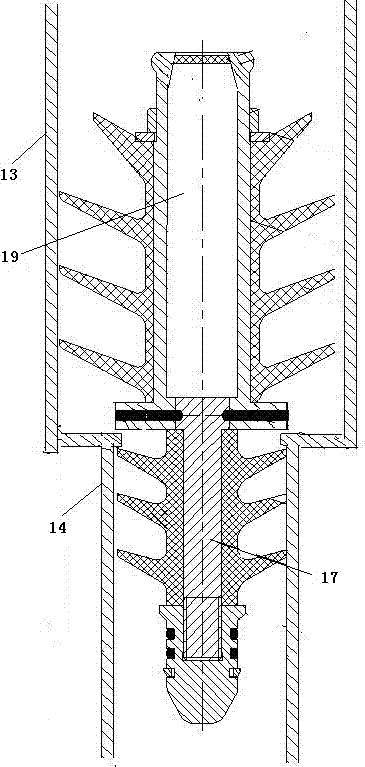

[0022] Such as figure 2 As shown, the combined self-locking variable-diameter rubber plug moves to the conversion position between the large casing 13 and the small casing 14, the upper rubber plug 19 is located in the large casing 13, the lower rubber plug 17 is located in the small casing 14, and the glue The pressure-bear...

Embodiment 2

[0027] On the basis of Example 1, further, the upper rubber plug 19 includes a first mandrel 6 and a rubber bowl sleeved on the outer wall of the first mandrel 6, and the rubber bowl is composed of the first rubber bowl 7 and the second rubber bowl. The first plastic bowl 7 has a diameter of 188 mm to 196 mm, and the second plastic bowl 5 has a diameter of 160 mm to 170 mm.

[0028] The diameter of the first rubber bowl 7 is larger than the maximum inner diameter of the large casing 13, which meets the requirements of cement scraping, and the first rubber bowl 7 is evenly spaced on the first mandrel 6, and the second rubber bowl 5 is similar to the first rubber bowl. The bowls 7 are evenly sleeved on the first mandrel 6 at equal intervals, and the first rubber bowl 7 is arranged near the end where the upper rubber plug 19 and the lower rubber plug 17 are connected.

Embodiment 3

[0030] On the basis of Embodiment 2, in particular, the outer wall of the first mandrel 6 is also sleeved with a joint cap 3 for fixing the rubber bowl at the end close to the tail of the upper rubber plug 19, and the joint between the cap 3 and the rubber bowl There is a top cap 4 sleeved on the first mandrel 6 for fixing the rubber bowl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com