Mineral offset adjusting excavator

An offset adjustment and excavator technology, which is used in slitting machinery, earth-moving drilling, etc., can solve the problems of inability to realize the excavation arm main body offset and walking, low production efficiency, and incomplete cleaning, etc. Economic benefits, low cost, and the effect of improving the speed of excavation and bottom cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

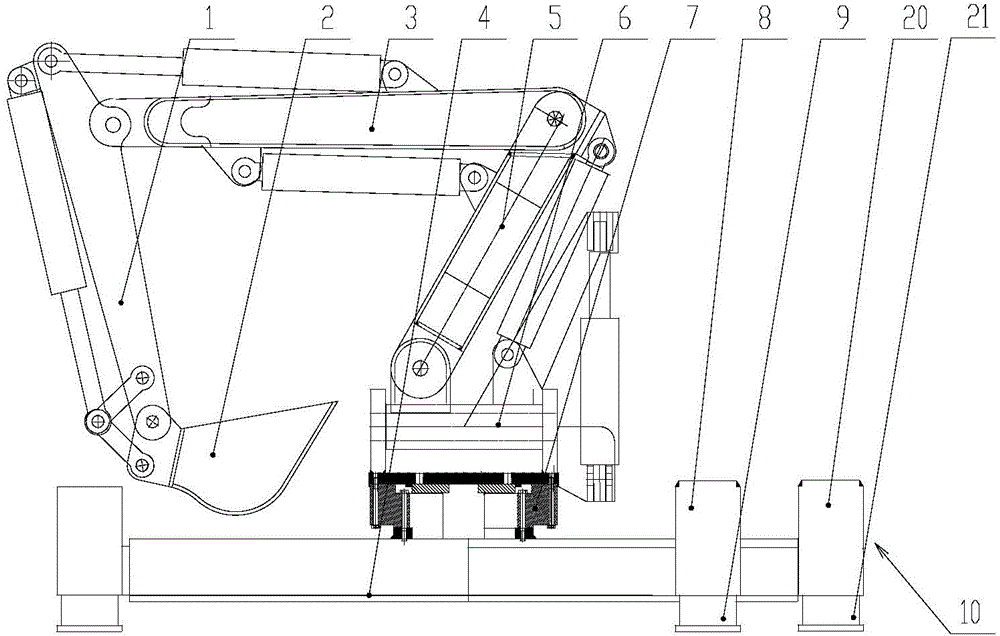

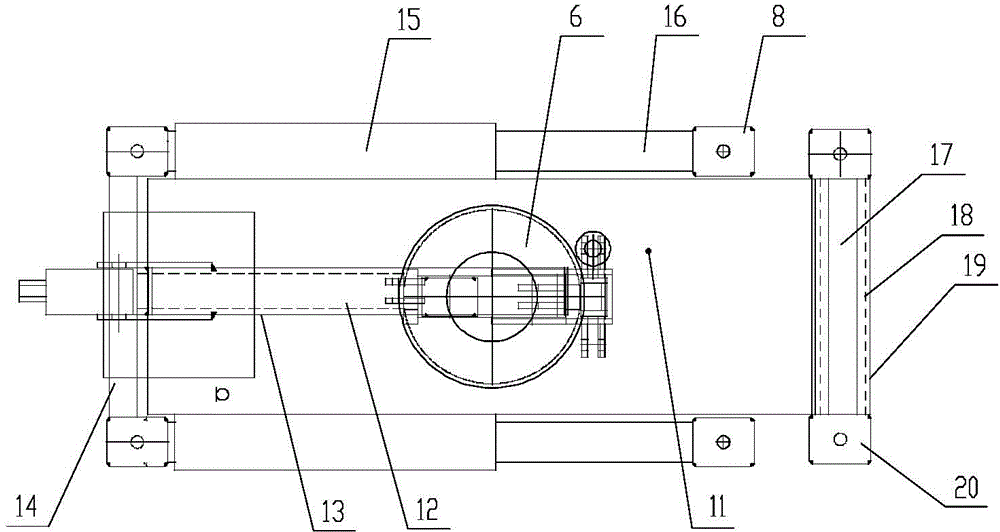

[0023] like Figure 1-Figure 2 As shown, the mining offset adjustment excavator of the present invention is composed of a stick 1, a bucket 2, an auxiliary arm 3, a traveling device 4, a main arm 5, a turning seat 6, a rotating seat 7, a walking support leg lifting seat 8, a walking support Leg lifting slider 9, offset adjustment device 10, base 11, travel hydraulic cylinder 12, excavating arm main body 13, travel front beam 14, travel side beam sleeve 15, travel side beam 16, offset hydraulic cylinder 17, offset Beam 18, offset beam sleeve 19, offset outrigger lifting seat 20, offset outrigger lifting slider 21, etc., the specific structure is as follows:

[0024] A swivel seat 7 is installed on the base 11, and an overturn seat 6 is arranged on the top of the swivel seat 7, and the overturn seat 6 and the excavating arm main body 13 installed on the overturn seat 6 are driven by the swivel seat 7 to rotate, and the overturn seat 6 drives the excavating arm main body 13 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com