One-inclined multi-vertical cascaded well group salt mine mining method

A mining method and technology of well groups, which are applied in surface mining, earthwork drilling, underground mining, etc., can solve the problems of restricting the progress of salt mine mining, exposed collapse and damage of the deflecting section, and improve the safety production level and mining efficiency. , The effect of improving brine quality and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

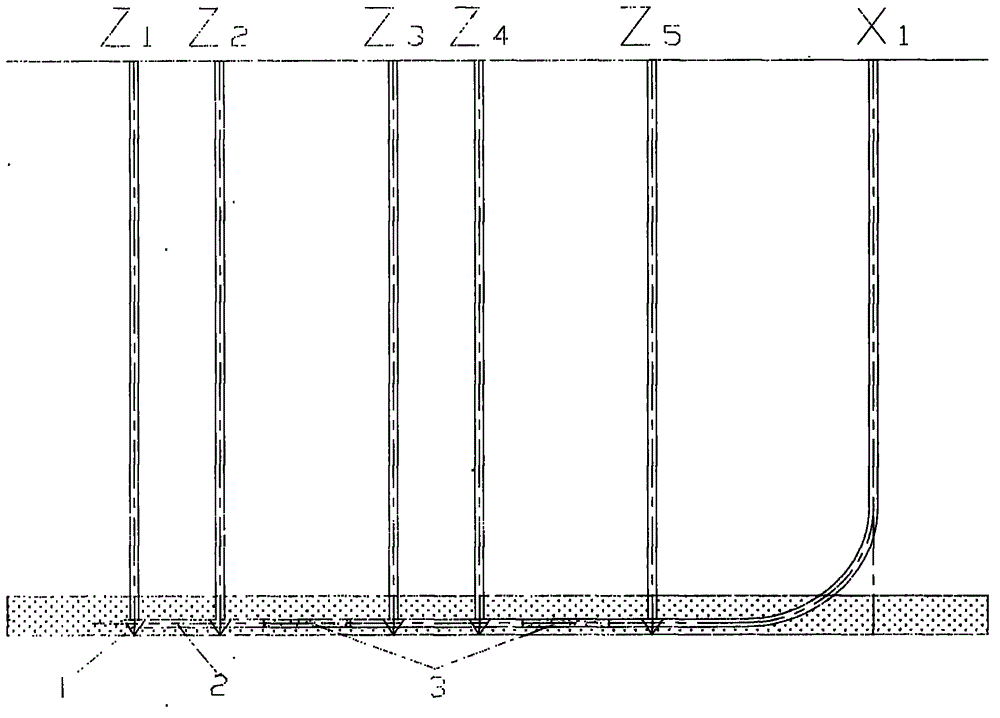

[0034] A certain salt mine, with a depth of 1,000 meters and a thickness of about 60 meters, was originally mined with a "straight-inclined" horizontal butt joint well group. Because there are many inclined wells, a large amount of resources near the boundary were wasted. The cost of drilling is increased, and brine wells are often blocked or even scrapped during the production process of deviated wells.

[0035] In the embodiment of the present invention, the well group string is designed as 6 wells, which are divided into 3 groups of wells, and the distance between the wellheads at both ends is 850 meters. The well spacing of the first group and the second group is 100 meters, and the third group is straight and inclined, the well spacing is 250 meters, and the radius of the arc curve of the deflection section is 150 meters. The distance between the well groups is 200 meters, and the length of the cement plug 3 in the horizontal section is 100 meters. The specific steps are:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com