Engine speed control method with online setting of PID (proportion integration differentiation) parameters

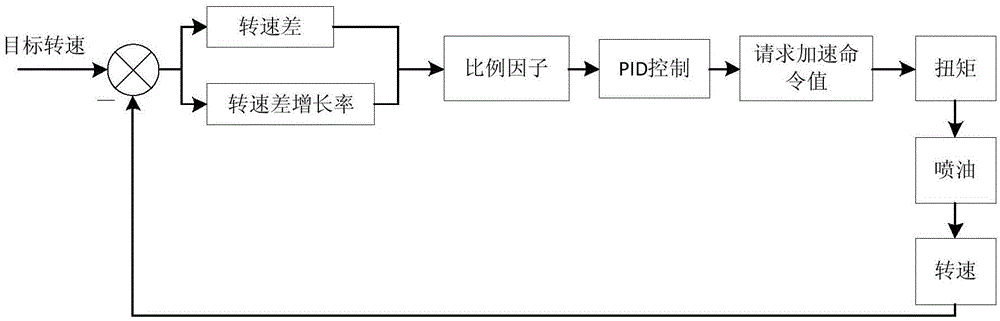

A technology of engine speed and control method, which is applied in engine control, machine/engine, electrical control, etc. It can solve the problems of slow response, long stabilization time, poor adaptability and flexibility of PID parameter adjustment, etc., to reduce overshoot, Improved dynamic response and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

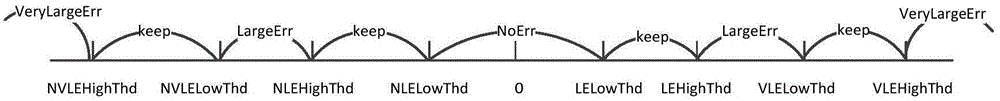

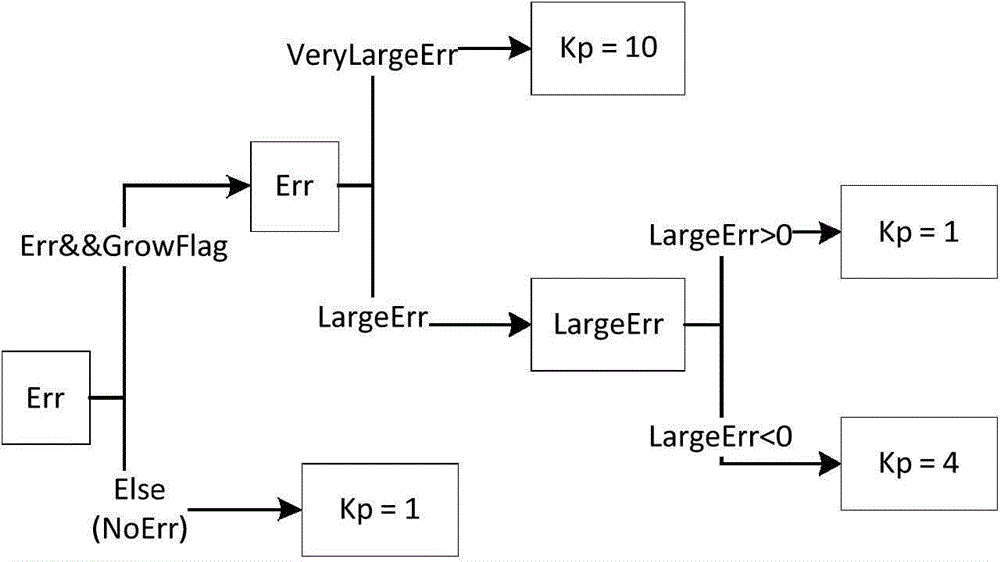

Method used

Image

Examples

Embodiment Construction

[0052]Taking the start-up idle speed control of an engine as an example, the idle speed is between 700rpm and 900rpm, and the speed fluctuation curve of the engine using traditional PID control and the speed fluctuation curve of the dynamic setting of engine proportional parameters are respectively measured. Scale parameter setting value see image 3 shown in . Figure 4 Shown is the engine idle speed adjustment process of traditional PID control, Figure 5 Shown is the process of adjusting the engine idle speed after adjusting the proportional parameters according to the method in this paper.

[0053] From Figure 4 and Figure 5 It can be seen from the figure that the response time of speed adjustment using ID dynamic parameter adjustment is significantly faster than that of traditional PID control; after stabilization, the maximum speed fluctuation using traditional PID control is about ±15rpm, and the speed fluctuation of dynamic setting proportional parameters in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com