Magnetic suspension rotor harmonic current suppression method based on composite friction repetitive controller

A repetitive controller and magnetic levitation rotor technology, applied in the direction of mechanical oscillation control, non-electric variable control, control/regulation system, etc., can solve the problems of harmonic current overshoot, limited convergence speed, etc., to reduce delay time, Improve the convergence speed and reduce the effect of overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

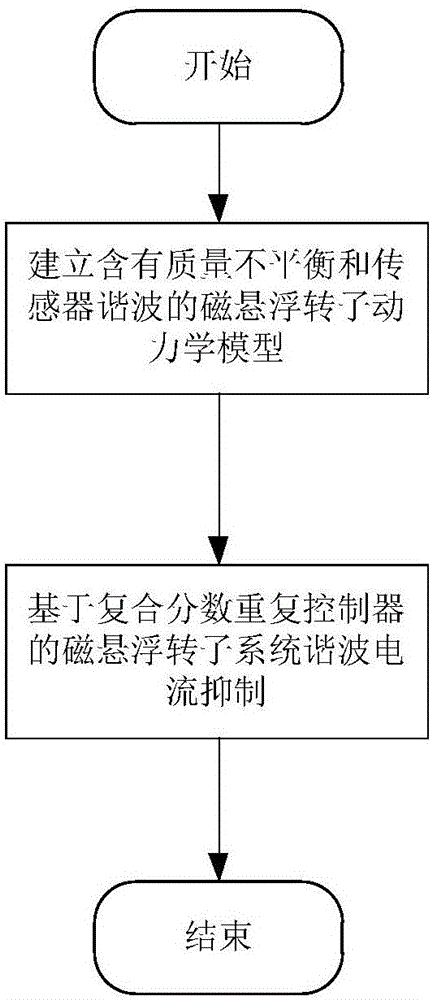

[0049] Such as figure 1 As shown, the implementation process of a maglev rotor harmonic current suppression method based on compound fractional repetitive controller is: firstly establish a maglev rotor dynamics model including mass unbalance and sensor harmonics, and then design a maglev rotor based on compound fractional repetitive control Harmonic current suppression method for magnetic levitation rotor.

[0050] (1) Establish a maglev rotor dynamics model with mass unbalance and sensor harmonics

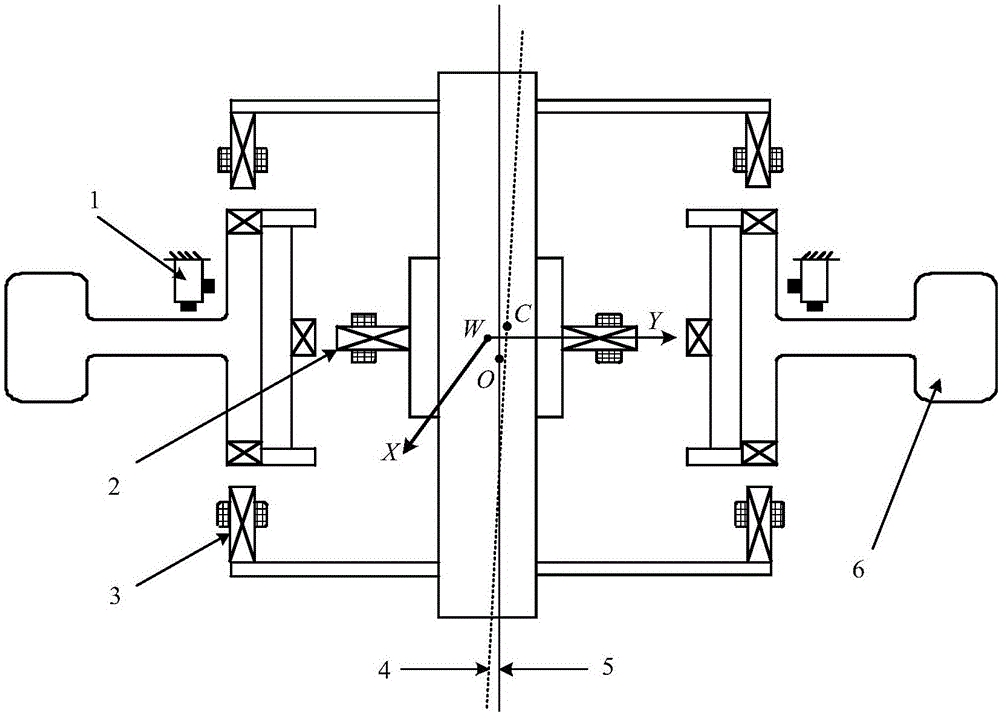

[0051] The schematic diagram of the magnetic levitation rotor system is as follows: figure 2 shown. Let the geometric center of the magnetic bearing stator be W, the geometric center of the rotor be O, and the mass center of the rotor be C, establish an inertial coordinate system WXY with W as the center, and (x, y) represent the coordinates of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com