Self-resetting friction-changing damper

A technology of variable friction and damper, which is applied in the direction of friction shock absorber, building components, anti-shock, etc. It can solve the problems that the variable friction damper does not have self-resetting function and limits the scope of engineering application, so as to save time and economic cost, Strong engineering applicability and the effect of reducing residual deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

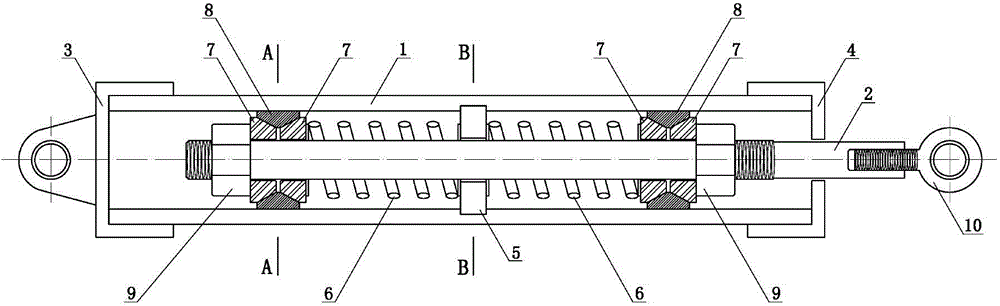

[0039] Please check Figure 1 to Figure 8 , a self-resetting variable friction damper, comprising:

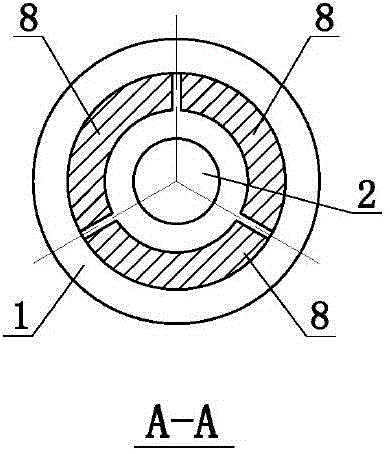

[0040] A cylinder body 1 is a steel cylinder, including a cylindrical structure formed by two half-cylinders welded together, and the middle parts of the two half-cylinders are provided with grooves extending along the radial direction of the cylinder wall;

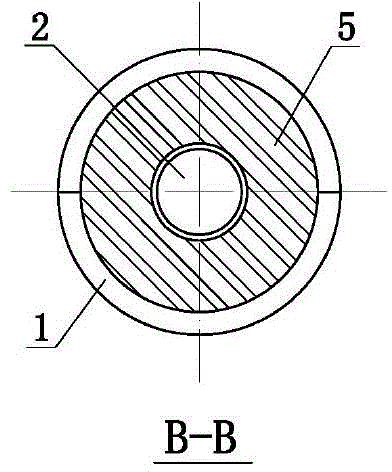

[0041] A baffle plate 5, in the shape of a ring, is fixed in the groove of the cylinder body 1 and has a through hole;

[0042] A sliding shaft 2 is a cylindrical solid steel rod that can relatively slide through the through hole of the baffle plate 5 and the first end of the sliding shaft 2 protrudes outside the cylinder 1; The central axis coincides;

[0043] Two fixed seats 9 are fixedly connected to the sliding shaft and located on both sides of the baffle plate 5;

[0044] A pair of damping mechanisms, connected to the sliding shaft 2 and located on both sides of the baffle 5, each damping mechanism includes an ela...

Embodiment 2

[0054] Please check Figure 9 , is another embodiment of the present invention, which is different from Embodiment 1 in that: the friction assemblies are two pairs, and the other pair of friction assemblies are respectively arranged between the elastic body 6 and the baffle plate 5; the elastic body 6 The two ends can bear against the friction components on both sides respectively. In this way, compared with Example 1, the number of friction components is increased, and the friction force provided by two pairs of friction components under the same loading conditions is theoretically double that of one pair of friction components. Therefore, Example 2 is comparable to Example 1. It has a stronger frictional energy dissipation capacity than

Embodiment 3

[0056] The difference between embodiment 3 and embodiment 1 is that the friction wedge 8 is made of powder metallurgy friction material, which has high friction coefficient, small wear, high strength, high temperature resistance, corrosion resistance and seizure resistance Good performance, less affected by oil and moisture. In short, among the existing friction materials, the stability and wear resistance of the friction coefficient of powder metallurgy friction materials are exceptionally outstanding, and the friction damper made of them as friction materials will have relatively more stable and reliable working performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com