Main drive gear of two-gear electric vehicle transmission assembly

A main transmission and electric vehicle technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve problems such as poor adaptability to road conditions, inability to change speed, inability to adjust, etc., to reduce weight and strength And the effect of good wear resistance and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

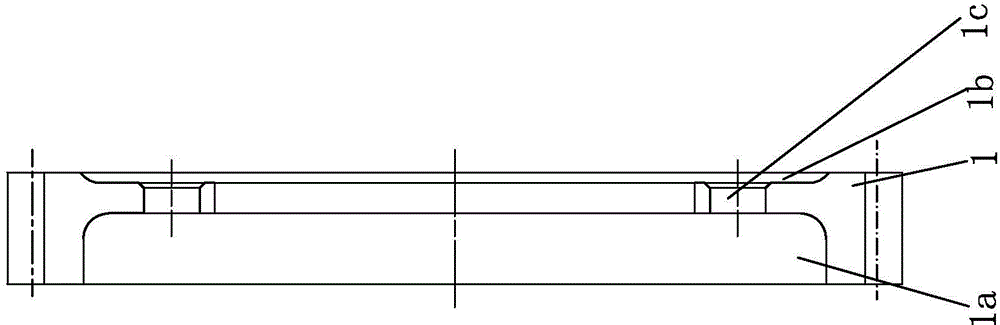

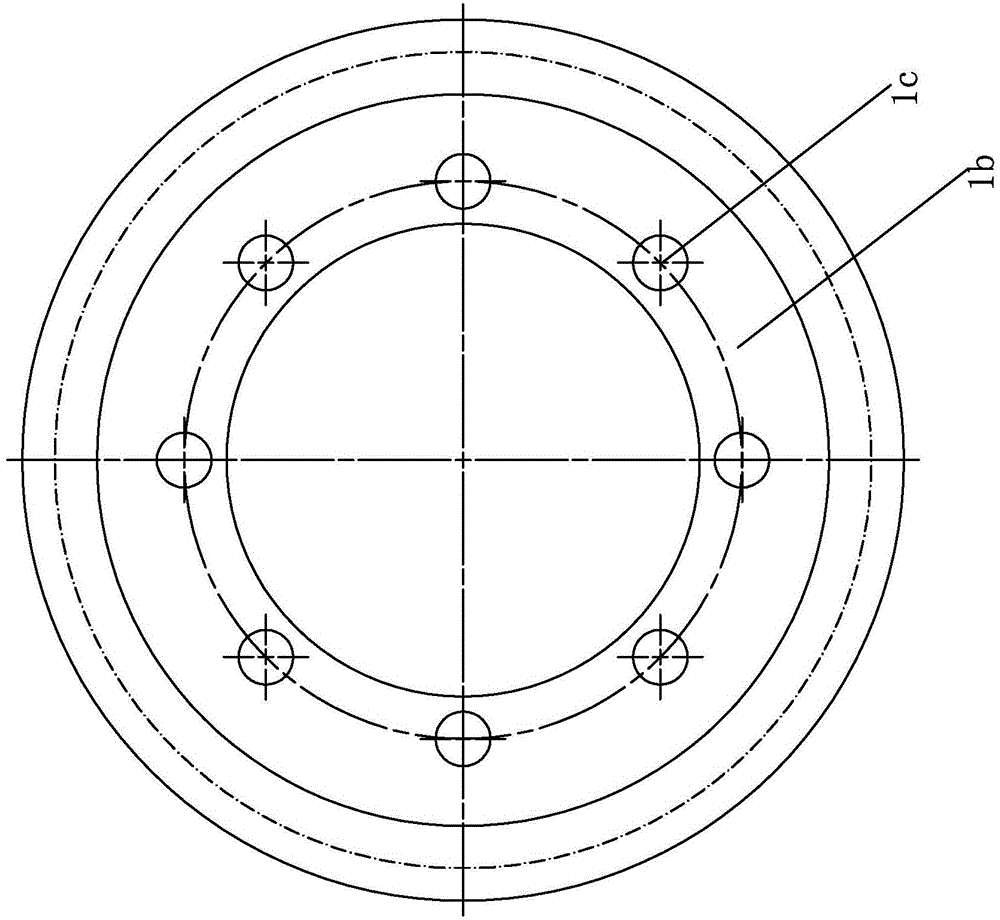

[0013] Such as figure 1 , 2 As shown, a main transmission gear of a second-speed electric vehicle transmission assembly, the main transmission gear body 1 is made of 20CrMnTiH, and is formed by forging. At the same time, the thickness of the body 1 is 22 mm, the diameter of the central hole of the body 1 is 95 mm, and the outer edge of the body 1 is in the shape of a ring of teeth. The center of the left end surface of the main body 1 is provided with a first weight reducing groove 1a, the diameter of the first weight reducing groove 1a is 147mm, and the depth of the first weight reducing groove 1a is 14mm. The center of the right end surface of the main body 1 is provided with a second weight reducing groove 1b, the diameter of the second weight reducing groove 1b is 147mm, and the depth of the second weight reducing groove 1b is 2mm. The body 1 is evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com