Gas cooker capable of continuously regulating firepower

A technology of gas cooker and firepower, which is applied in valve details, heating fuel, home appliances, etc. It can solve the problems of increasing product cost, few firepower adjustment gears, and energy waste, so as to improve heating efficiency, flexibly adjust and prevent wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

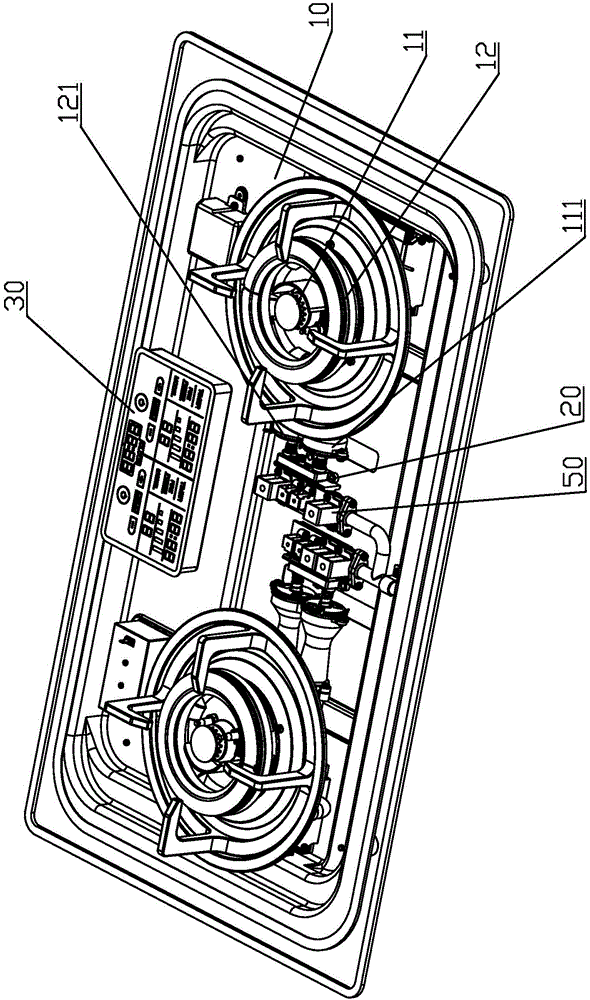

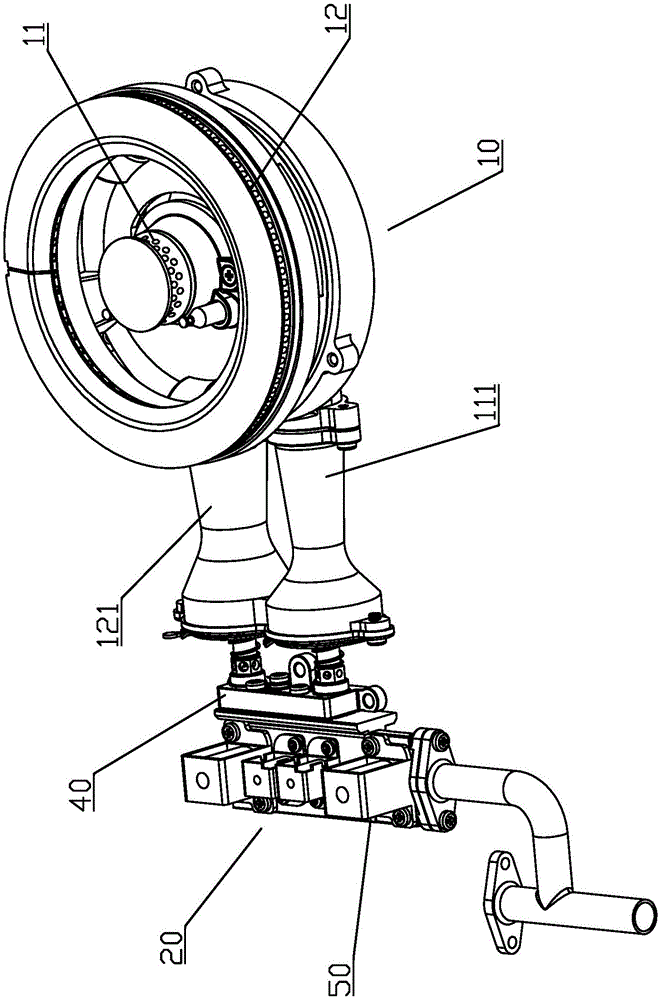

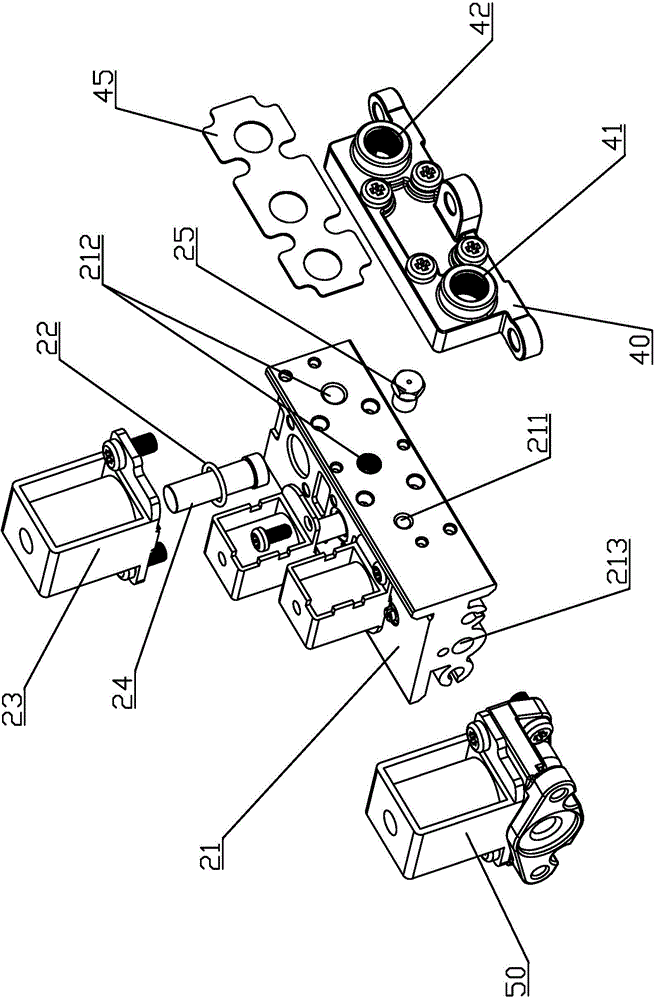

[0017] refer to Figure 1 to Figure 4 , a gas cooker that can continuously adjust the firepower, including a burner 10, a solenoid valve 20, a solenoid master valve 50 and a controller 30, the burner 10 includes an inner ring nozzle 11 that communicates with the solenoid valve 20 through an inner ring gas delivery pipe 111 And the outer ring nozzle 12 communicated with the solenoid valve 20 through the outer ring gas pipeline 121, the inner ring nozzle 11 is smaller than the outer ring nozzle 12 and is located at the center of the outer ring nozzle 12, the main gas valve is arranged at the inlet of the gas source and the solenoid valve 20 Between the gas ports 213, the solenoid master valve 50 can control the total amount of gas entering the solenoid valve 20, and at the same time can play the role of a safety switch to ensure safe use. The access between the valves 20 is convenient for maintenance.

[0018] The solenoid valve 20 includes a valve body 21, the valve body 21 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com