Method for determining content of lanthanum, cerium, praseodymium, neodymium and samarium in iron-containing dust sludge

A technology for iron dust sludge and dust sludge is applied in the field of cerium, neodymium, praseodymium, samarium content, determination of lanthanum in iron-containing dust sludge, and can solve the problems of no method for rare earth element detection, inability to perform component detection, and high detection lower limit. Achieve good application effect, shorten sample processing time and accurate analysis results

Inactive Publication Date: 2015-04-01

INNER MONGOLIA BAOTOU STEEL UNION

View PDF4 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there is currently no method for the detection of rare earth content in iron-containing dust, especially for the detection of the respective content of each rare earth element.

[0003] So far, there are many methods for the determination of rare earths, such as the oxalate gravimetric method, the chloro

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

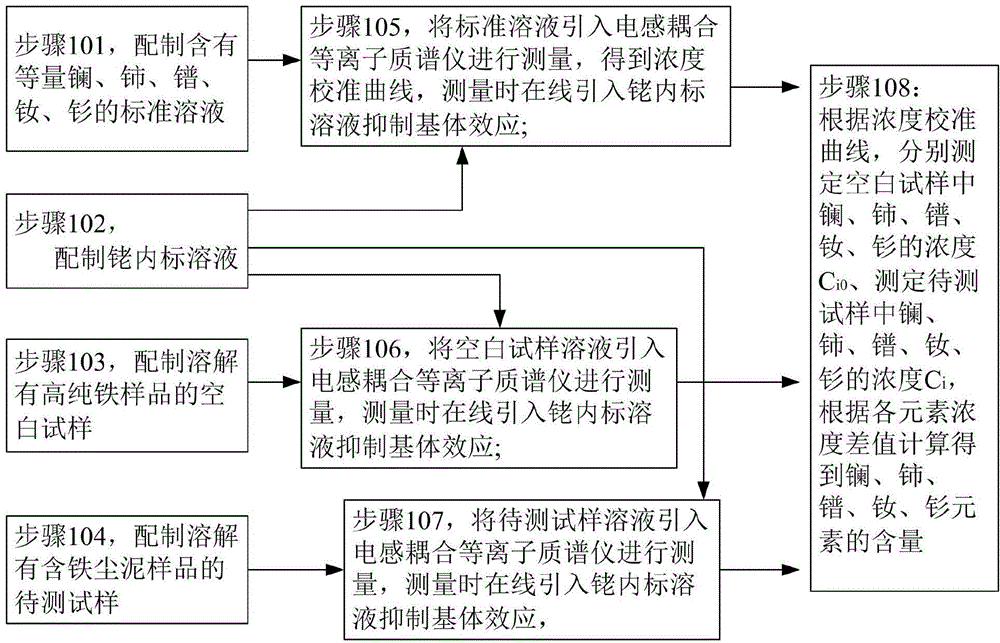

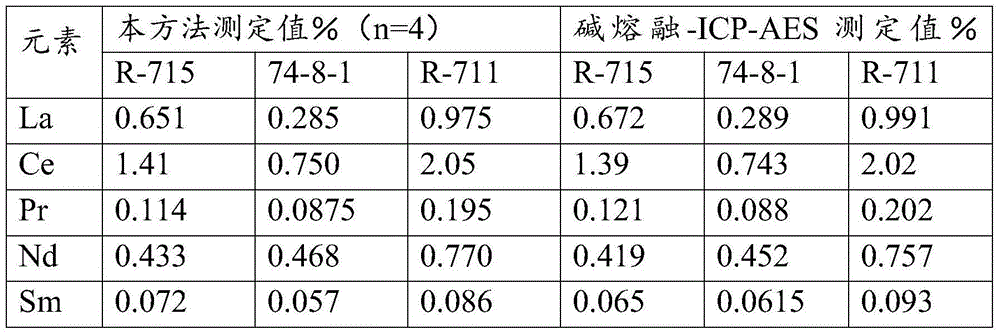

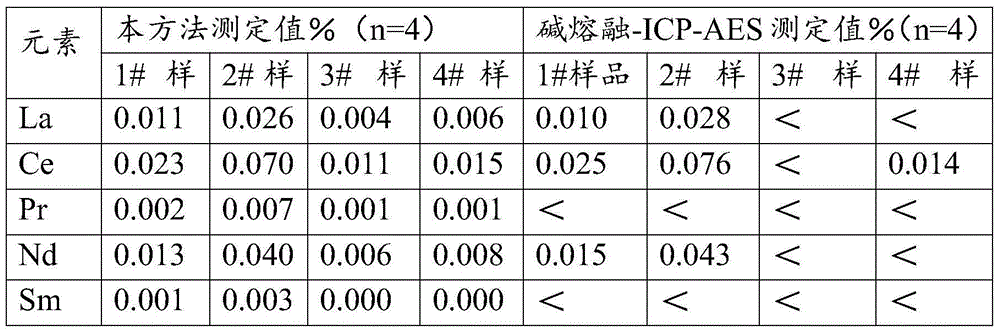

The invention discloses a method for determining content of lanthanum, cerium, praseodymium, neodymium and samarium in iron-containing dust sludge. The method comprises the following steps: preparing a standard solution containing lanthanum, cerium, praseodymium, neodymium and samarium, preparing a rhodium internal standard solution, preparing a blank test sample with dissolved high-purity iron sample, and preparing a to-be-detected test sample with dissolved iron-containing dust sludge sample; introducing the standard solution into an inductance coupling plasma mass spectrometry to be measured to obtain a concentration calibration curve, then testing the blank test sample solution and the to-be-detected test sample solution in the inductance coupling plasma mass spectrometry, determining the concentration of the lanthanum, cerium, praseodymium, neodymium and samarium in the blank test sample and the to-be-detected test ample as CiO and Ci according to the concentration calibration curve, and then calculating the content of each element in the iron-containing dust sludge to-be-detected test sample according to the concentration difference value (Ci-CiO). The method has the characteristics of high sensitivity, high determination speed, simplicity in operation and small interference.

Description

technical field [0001] The invention relates to the technical field of iron and steel metallurgical analysis, in particular to a method for measuring the contents of lanthanum, cerium, praseodymium, neodymium and samarium in iron-containing dust. Background technique [0002] Lanthanum, cerium, praseodymium, neodymium and samarium are the main rare earth elements in Baotou mine. It is often lost into iron-containing dust such as tailings, fly ash, and iron slag in the process of ore dressing, steelmaking, and ironmaking. It is a component that can be recycled in steelmaking production. important. However, there is currently no method for the detection of rare earth content in iron-containing dust, especially for the detection of the respective content of each rare earth element. [0003] So far, there are many methods for the determination of rare earths, such as the oxalate gravimetric method, the chlorophosphine-III photometric method, and the EDTA volumetric method. The...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N27/62G01N27/626

Inventor 卢艳蓉

Owner INNER MONGOLIA BAOTOU STEEL UNION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com