Sight glass device used for monitoring internal operation of mechanical case body

A machine and box technology, applied in the fields of mechanical operation monitoring, operation, and maintenance, can solve the problems of limited visual area, inability to quantitatively grasp the operation status, and inability to grasp the overall state of the internal structure, and achieve the effect of improving efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

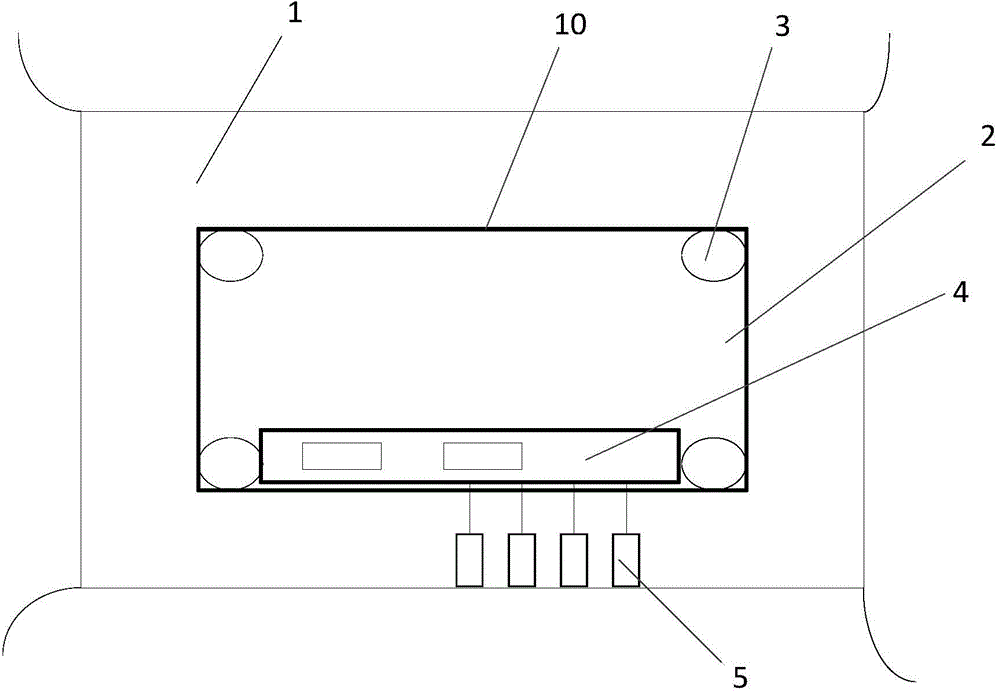

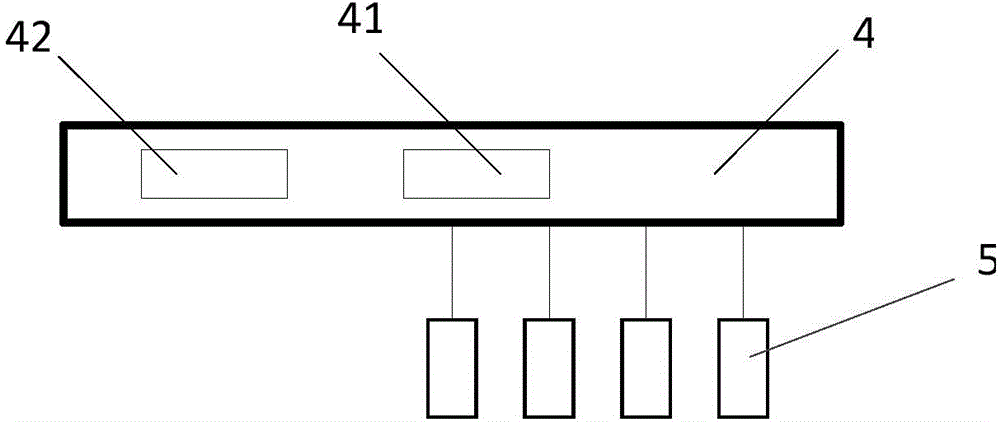

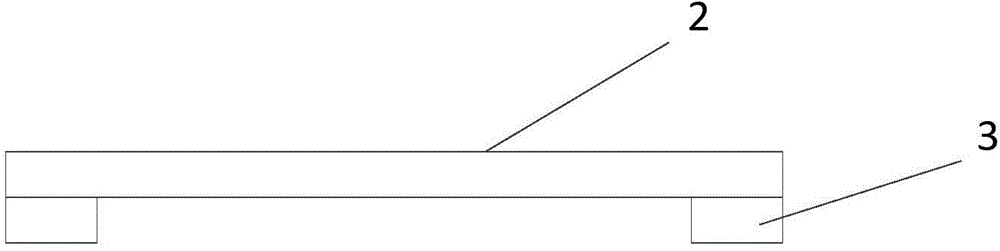

[0020] In order to be able to see through and monitor the internal structural state and running state of the machine, the present invention provides a sight glass device for monitoring the internal running of the machine box. Such as figure 1 As shown, the embodiment of the present invention includes a frame-shaped housing 10, a transparent display screen 2 located in the housing 10, an illumination source 3, and a circuit board 4, and a control chip 42 and a central processing unit 41 are integrated on the circuit board 4, wherein The casing 10 is fixed on the mechanical case 1 by screws provided on the edge. In addition, the embodiment of the present invention also includes a plurality of sensors 5 installed inside the mechanical box 1 .

[0021] Specifically, the transparent display screen 2 is fixedly arranged on the viewing win...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap