Method of laying prepreg by aid of trajectory planning software

A trajectory planning and prepreg technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of reducing the mechanical properties of laminated boards, increasing porosity, affecting the appearance of laminated boards, etc., and achieve structural mechanical properties The effect of increasing stability, reducing scrap rate of parts, and improving laying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Taking the 45° layup of a large curvature curved surface composite material part as an example, and in conjunction with the accompanying drawings, the present invention is further described in detail:

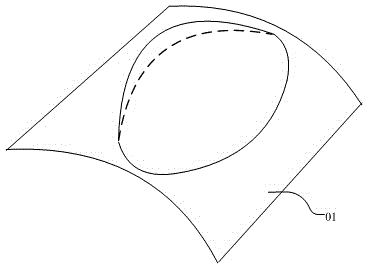

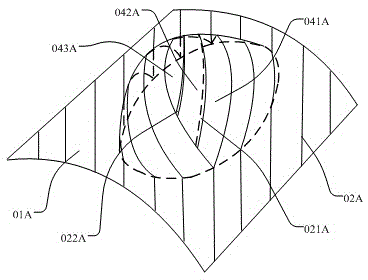

[0026] Surface 01 to be placed is a complex, non-developable curved surface composed of a circular cylinder and a convex hyperboloid, with a length and width of about 700mm and a height of about 500mm, such as figure 1 . It is impossible to use the whole prepreg to cover the non-expandable curved surface without lap / gap and wrinkle; while the temporary gesture and cut prepreg cannot accurately position the lap / gap and wrinkle, which will prolong the working hours and Affect the subsequent laying quality.

[0027] According to the present invention, its implementation process is as follows:

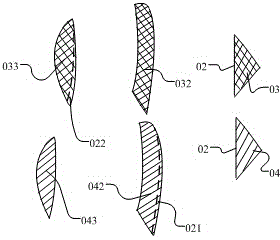

[0028] (1) Import the 3D CAD model of curved surface 01 into the trajectory planning software, lay out the plies according to its curvature, loading and other requirements, and set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com