Method for improving finite element analysis accuracy of transmission case

A transmission housing, analysis accuracy technology, applied in instruments, special data processing applications, electrical digital data processing, etc., can solve the problems of the finite element analysis simulation accuracy of the housing, large structural stress, torque consumption and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

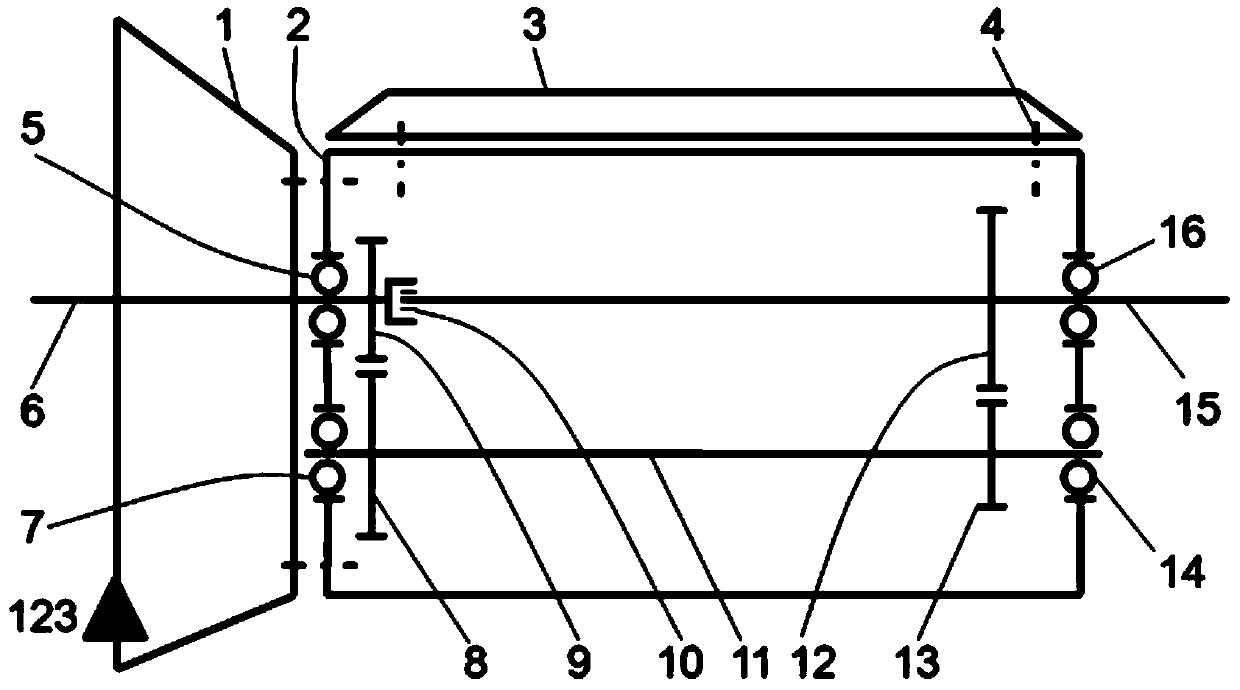

[0061] Such as figure 1 , figure 2 , image 3 As shown, a method for improving the accuracy of the finite element analysis of the transmission housing, which includes the following steps:

[0062] 1. Establish the finite element model of the transmission housing: respectively for the clutch housing 1, the transmission housing 2, the upper cover 3, the bolt 4, the input shaft front bearing 5, the intermediate shaft front bearing 7, the intermediate shaft rear bearing 14, the output shaft front Bearing 10, output shaft rear bearing 16, input shaft 6, intermediate shaft 11, output shaft 15, constant meshing driven gear 8, constant meshing driving gear 9, first gear driven gear 12, first gear driving gear 13 etc. Grid division, and then assemble them together by defining the contact relationship between the contact parts. The following rules need to be followed when dividing the mesh, that is, the finite element mesh of the contact part of the parts should be finely divided, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com