High-efficiency discharging feedback type battery charging power source

A battery charging and feedback technology, applied in battery circuit devices, charge balancing circuits, arrangement of multiple synchronous batteries, etc., can solve the problem of high charging harmonic content, increased power loss in power transmission and distribution, grid harmonic loss, and grid distortion. and other problems to achieve the effect of improving power supply power factor, improving power quality and avoiding harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

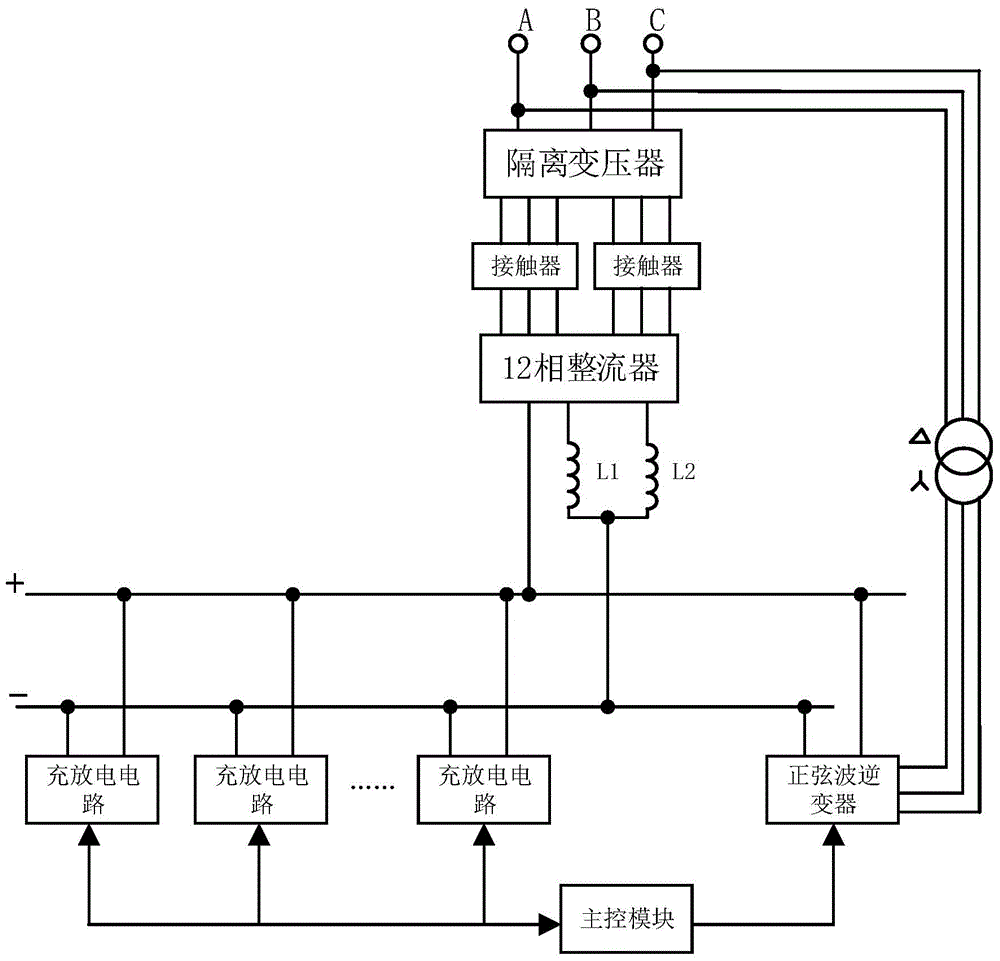

[0017] figure 1 It shows the functional block diagram of the common bus recharging power supply for large dense batteries.

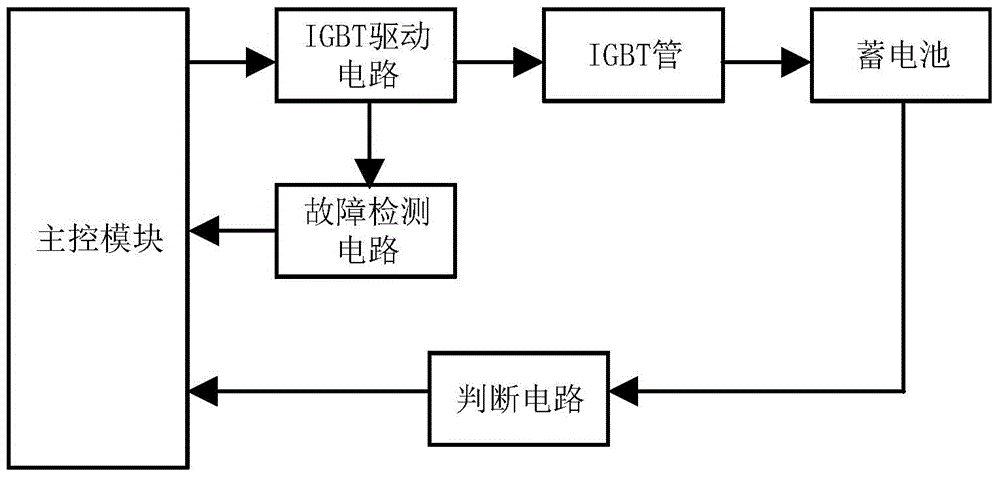

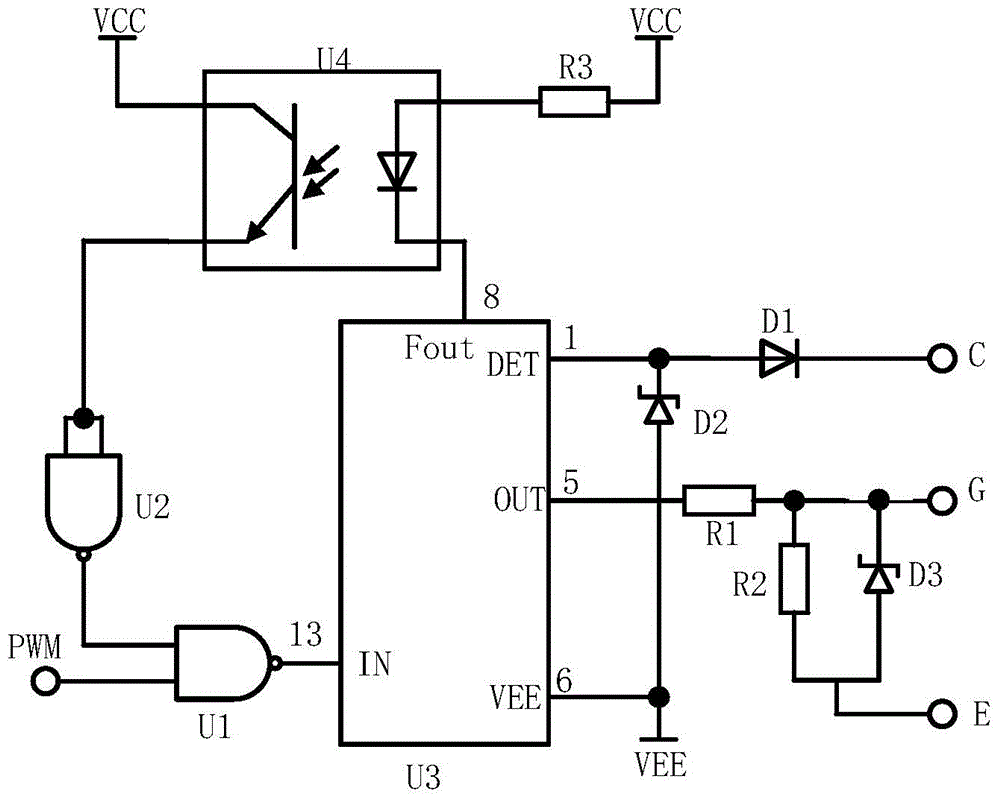

[0018] Such as figure 1 As shown, a high-efficiency discharge feedback battery charging power supply includes a main control module and an isolation transformer connected to the three-phase power supply terminal. The secondary of the isolation transformer is connected in star and delta, and the output terminals of star and delta are The two input ends of the 12-phase rectifier are connected through two interlocking contactors, and the output ends of the 12-phase rectifier are respectively connected through corresponding filter inductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com