A high-power photovoltaic cabinet body

A high-power, cabinet technology, applied in the field of new energy power generation, can solve the problems of large cabinet size, large number of busbars, and increased cabinet weight, so as to achieve reasonable internal space layout, uniform distribution of busbar heat dissipation, and internal structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the drawings and specific embodiments. The following embodiments are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

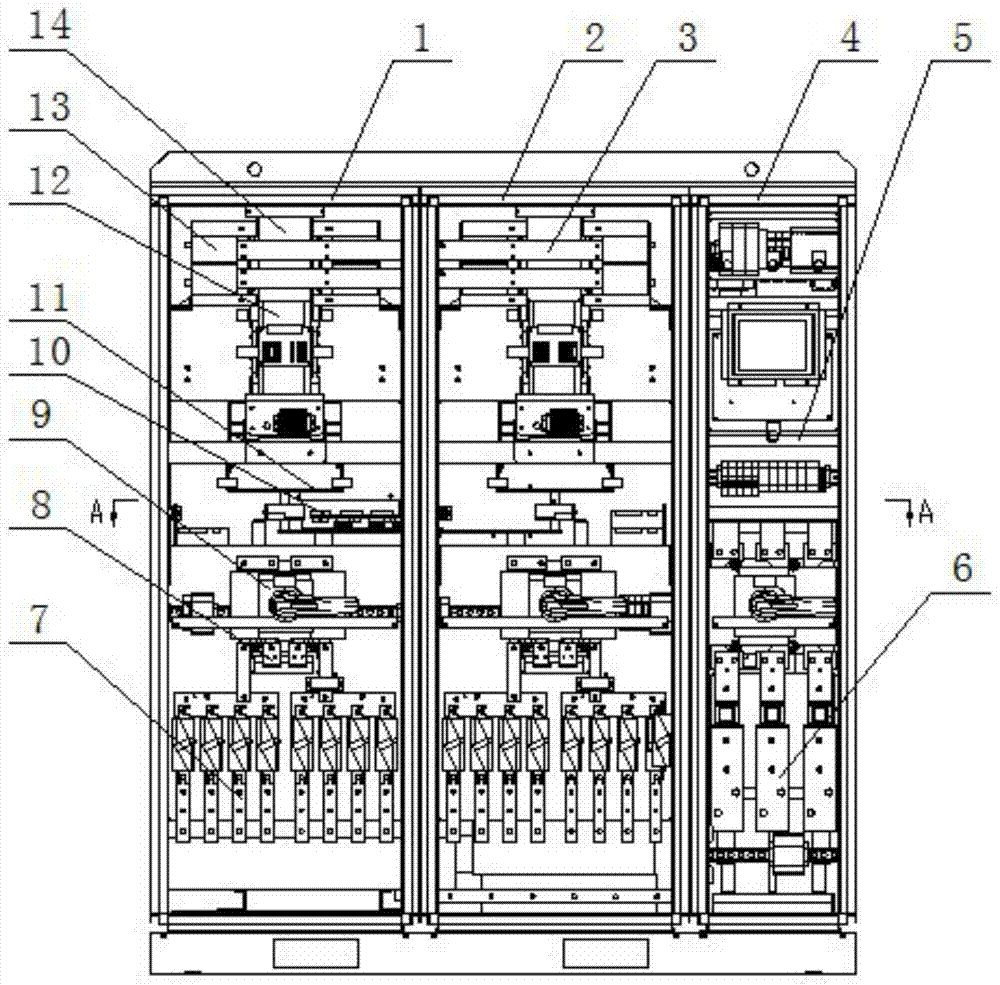

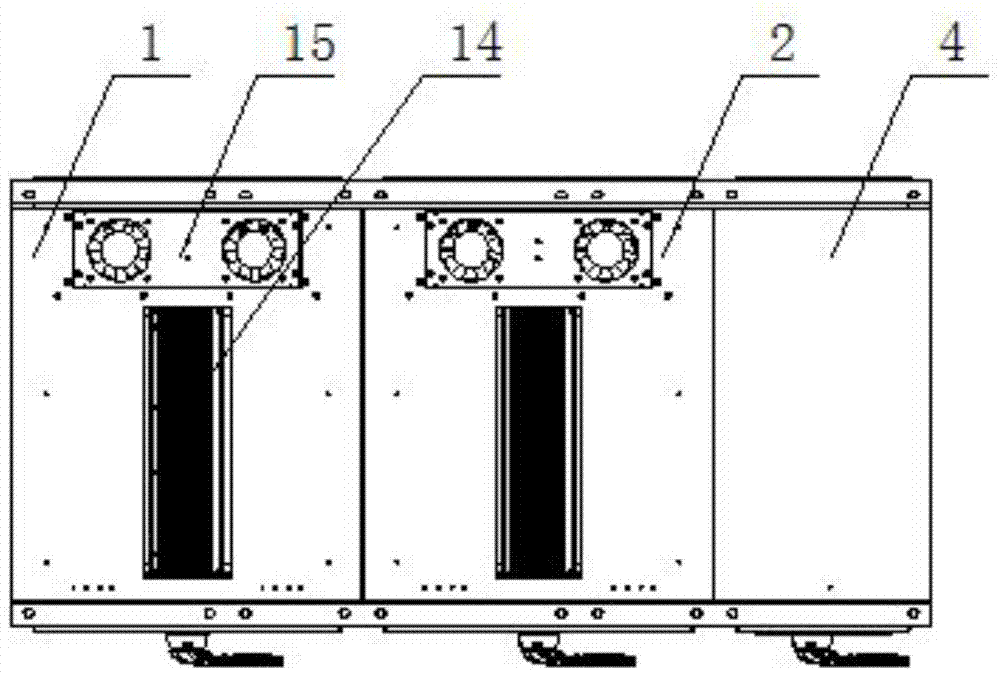

[0029] A high-power photovoltaic combined cabinet body, which is composed of an AC inlet cabinet 4, a left inverter cabinet 1 and a right inverter cabinet 2. The cabinets of three electrical cabinets are fixed side by side to form an overall cabinet frame. The wire cabinet is on the far right.

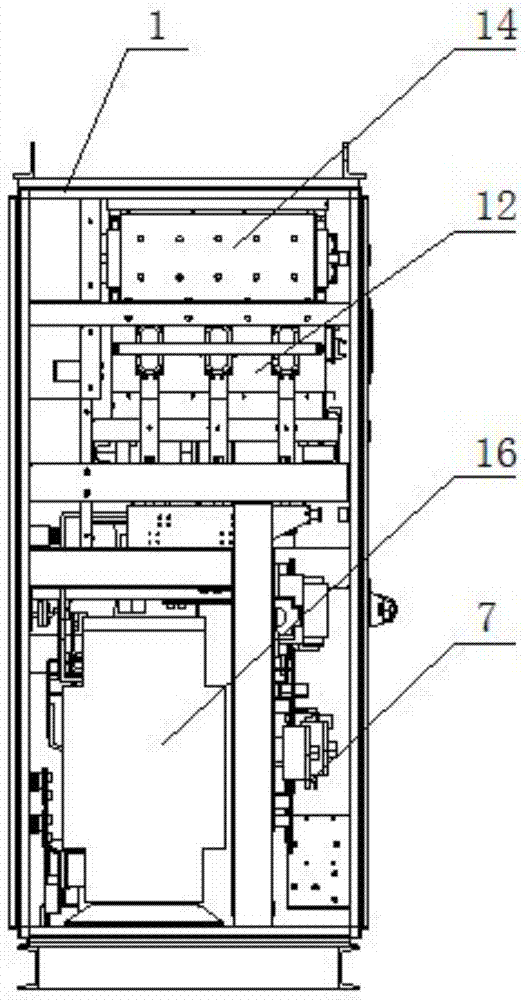

[0030] The structure of the left and right inverter cabinets is as follows:

[0031] The power components 13 are fixed in the upper part of the inverter cabinet. The power components are installed on the radiator 12. The front part of the lower part is provided with a circuit breaker 9 and the incoming busbar 7, and the rear part of the lower part is equipped with a reactor assembly 16 and so on. The inverter cabinet has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com