Coarse-cereals noodle carding machine

A technology for miscellaneous grain noodles and noodle preparation, which is applied in the fields of dough processing, baking, food science, etc., and can solve problems such as affecting eating, instant noodles becoming lumpy, and instant noodles affecting the effect of frying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

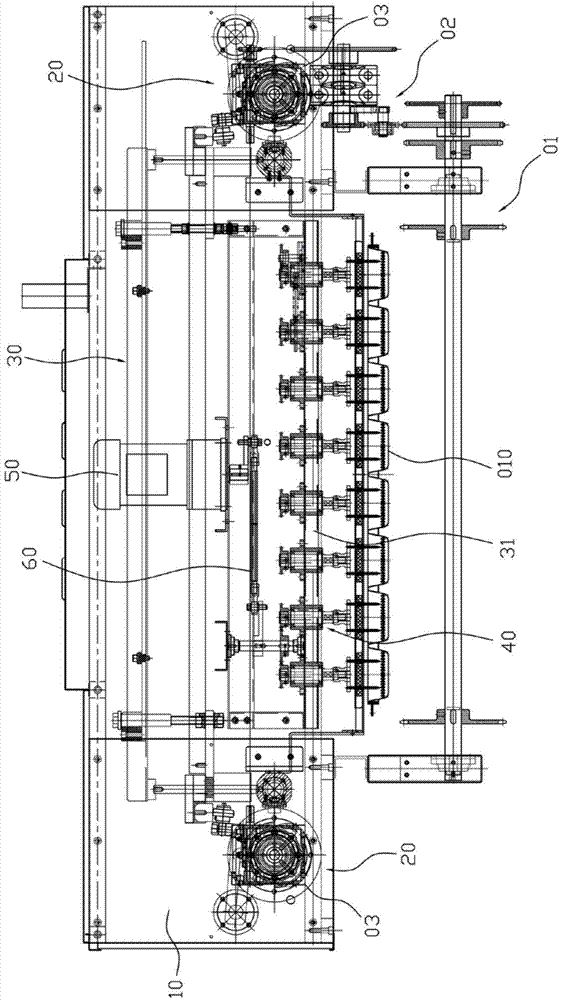

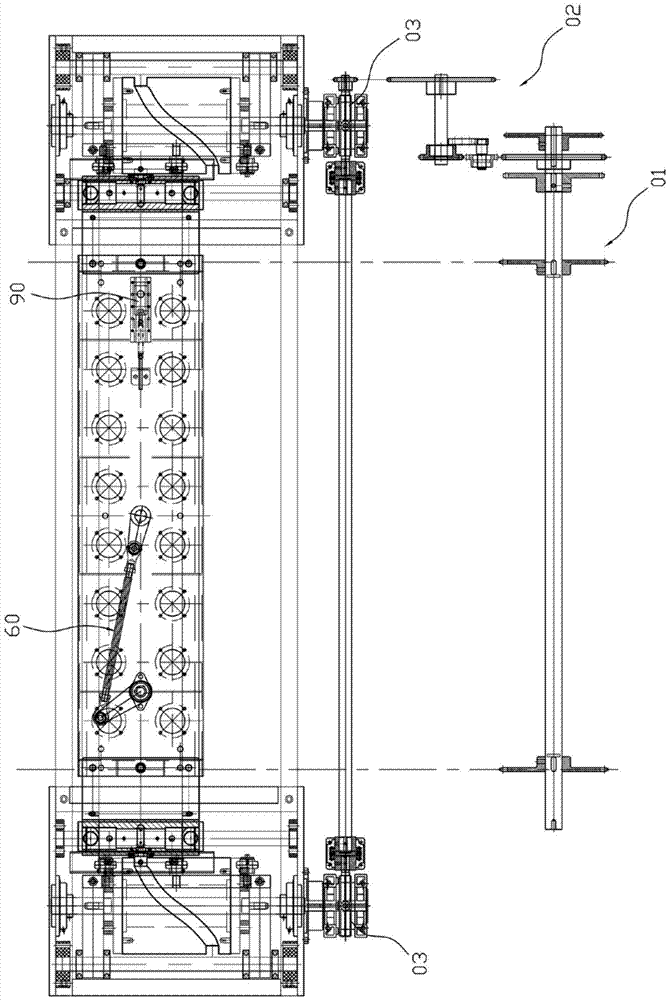

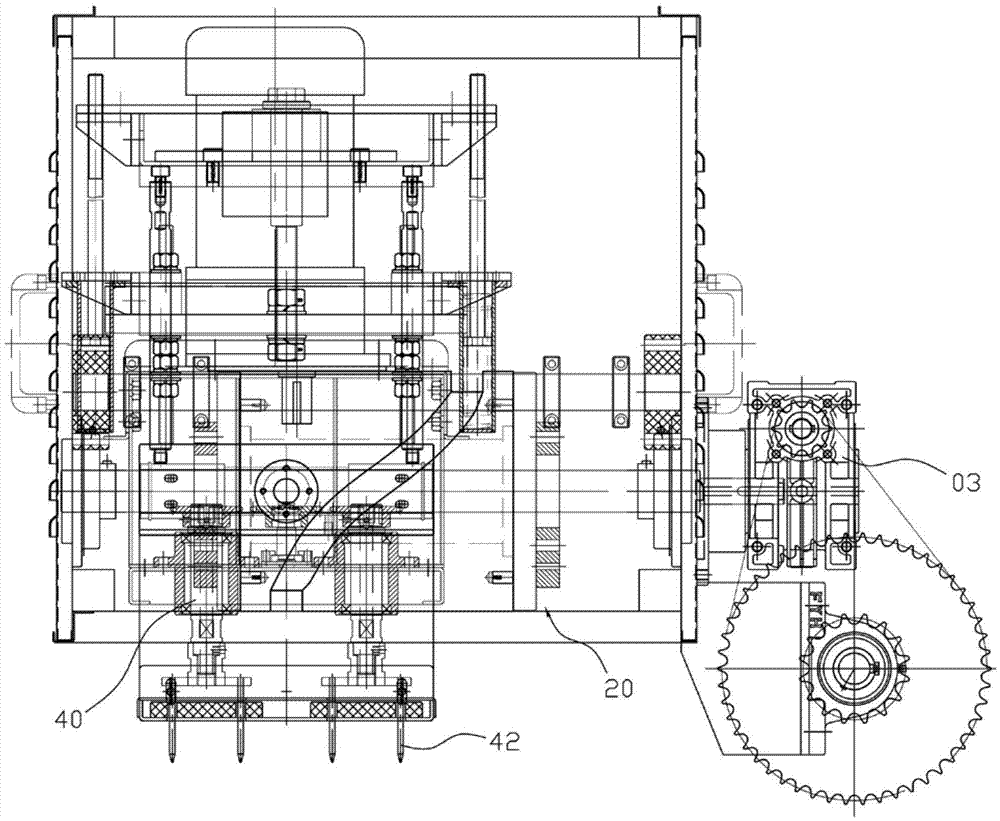

[0032] Such as figure 1 or Figure 4 Shown, a kind of miscellaneous grain noodle machine comprises a frame 10, a pair of cam combination mechanisms 20, a noodle support 30, and a noodle head 40.

[0033] Such as figure 1 or Figure 4 As shown, the pair of cam combination mechanisms 20 are installed on the frame 10 and located on both sides of the surface support 30 . Such as Figure 6 , Figure 7 As shown, the cam combination mechanism 20 includes a cylindrical cam mechanism 21 and an ordinary cam mechanism 22, the cylindrical cam mechanism 21 drives the noodle support 30 to move horizontally, and the ordinary cam mechanism 22 drives the noodle support 30 to move up and down. The cylindrical cam mechanism 21 includes a cylindrical cam 211 and a first follower 212, the ordinary cam mechanism 22 includes an ordinary cam 221 and a second follower 222, the cylindrical cam 211 and the ordinary cam 221 are coaxial, the The quantity of ordinary cam 221 is two, and described two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com