A kind of sulfur-free pear chips and preparation method thereof

A technology for pear slices and chips, which is applied in the fields of sulfur-free pear chips and its preparation, pear chips and its preparation, can solve the problems of nutrient loss and slow drying rate, achieve less nutrient loss, convenient operation, The effect of maintaining color quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1, the preparation of sulfur-free pear chips

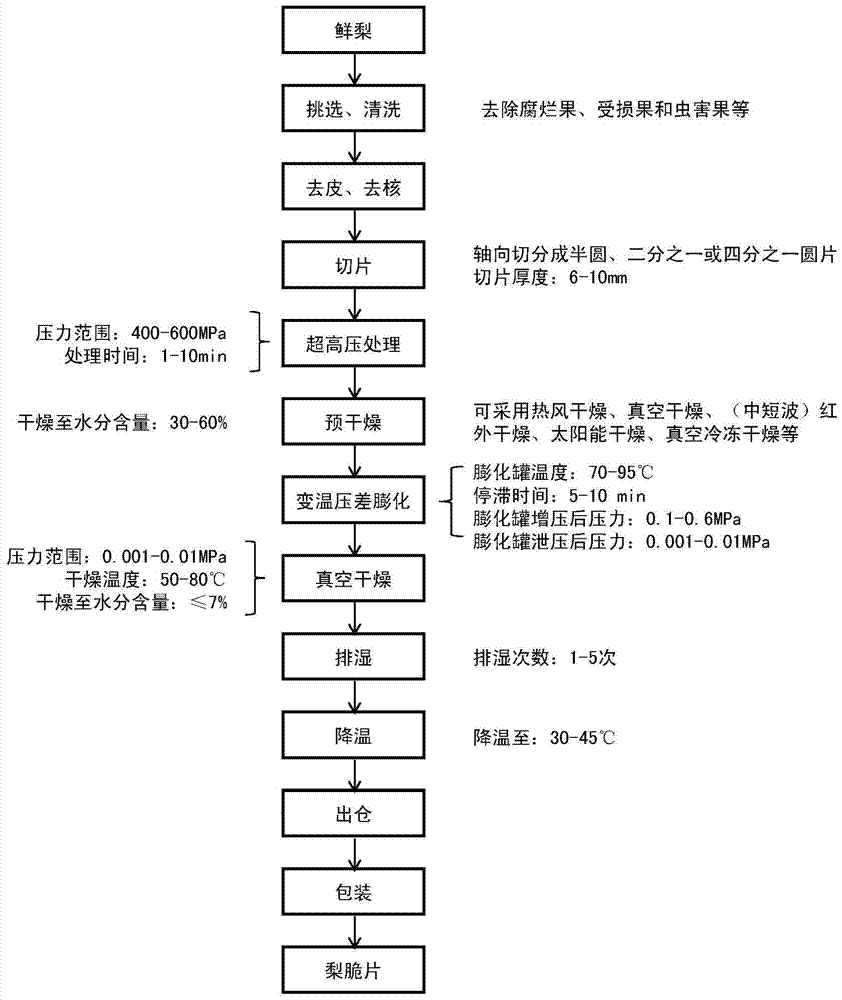

[0052] The schematic flow sheet of preparation method of the present invention is as figure 1 shown.

[0053] 1. Preparation of sulfur-free pear chips

[0054] (1) Pretreatment of pears:

[0055] 1) Fruit selection and cleaning: select nine-ripe Fengshui pears, remove damaged, deformed and pest-infested fruits, and then clean them;

[0056] 2) Peeling and core removal: manually or mechanically remove the skin and core from the pears cleaned in step (1);

[0057] 3) Slicing: the pear pulp after the peeling and pitting in step (2) is axially cut into 1 / 4 round slices with a thickness of 6 mm through a slicer to obtain sliced pears.

[0058] (2) Ultra-high pressure treatment: The pear slices obtained in step (1) were subjected to ultra-high pressure treatment at a pressure of 500 MPa and a temperature of 25° C., and the processed pear slices were obtained after treatment for 5 minutes.

[0059] (3) Pre-drying...

Embodiment 2

[0108] Embodiment 2, the preparation of sulfur-free pear chips

[0109] The preparation method of sulfur-free pear chips in the present embodiment is the same as the step in Example 1, except that:

[0110] The slice thickness of pear slice is 7mm in the step (1);

[0111] The pressure of the ultra-high pressure treatment in the step (2) is 550MPa, and the treatment time is 2.5min;

[0112] The pre-drying in step (3) adopts vacuum drying, the drying temperature is 65° C., the vacuum degree is 0.004 MPa, the time is 60 min, and the pre-drying is carried out until the mass moisture content is 45%;

[0113] In the step (4), the variable temperature and pressure difference puffing and drying, the temperature in the puffing tank is 90°C, and the high-pressure gas is not filled, and the step (4) is repeated 3 times;

[0114] The vacuum drying pressure in step (5) is 0.002MPa, and the number of times of dehumidification is 3 times.

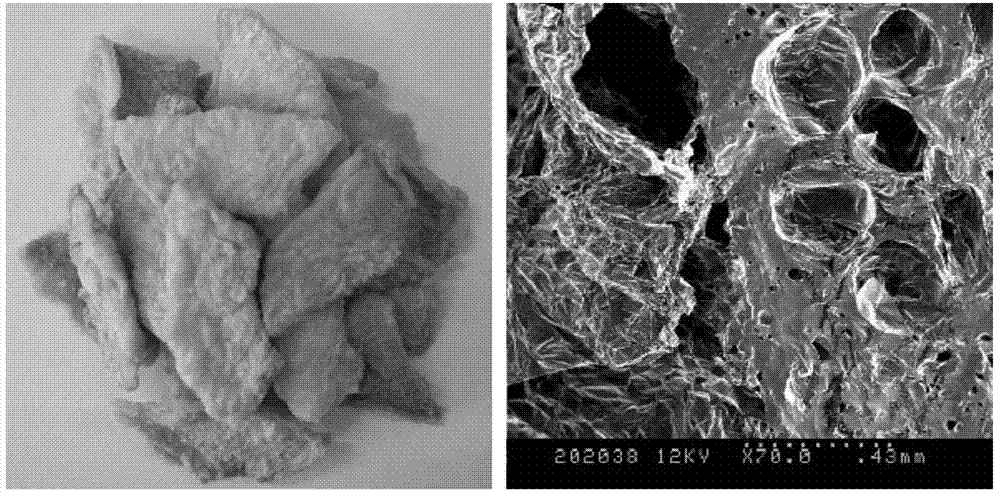

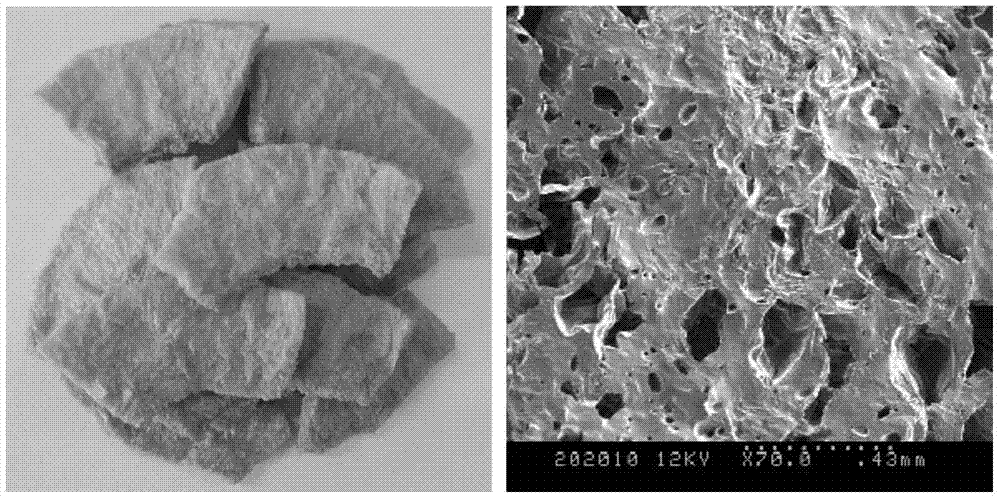

[0115] Such as Figure 5 Shown is the appearan...

Embodiment 3

[0118] Embodiment 3, the preparation of pear chips without sulfur

[0119] The preparation method of sulfur-free pear chips in the present embodiment is the same as the step in Example 1, except that:

[0120] The pressure of ultra-high pressure treatment in step (2) is 400MPa, and the treatment time is 6min;

[0121] The pre-drying in step (3) adopts medium and short-wave infrared drying, the drying temperature is 65 ° C, the time is 40 min, and the pre-drying is until the mass moisture content is 35%;

[0122] In step (4), the temperature and pressure difference are expanded and dried, and the temperature in the expanded tank is 90°C. Fill the expansion tank with high-pressure air to increase the pressure of the expansion tank to 0.2MPa. Expanding and drying repeated operation 2 times;

[0123] Step (5) The pressure of vacuum drying is 0.002MPa, and the number of dehumidification is 3 times;

[0124] The packaging in the step (6) post-processing adopts polyethylene packa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com