A Machine Vision Intelligent Capsule Filling System

A machine vision and filling system technology, applied in capsule delivery, drug delivery, pharmaceutical formulations, etc., can solve the problems of large area of production equipment, low production efficiency, long assembly line, etc., so as to reduce labor costs and improve production efficiency. , the effect of reducing the error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

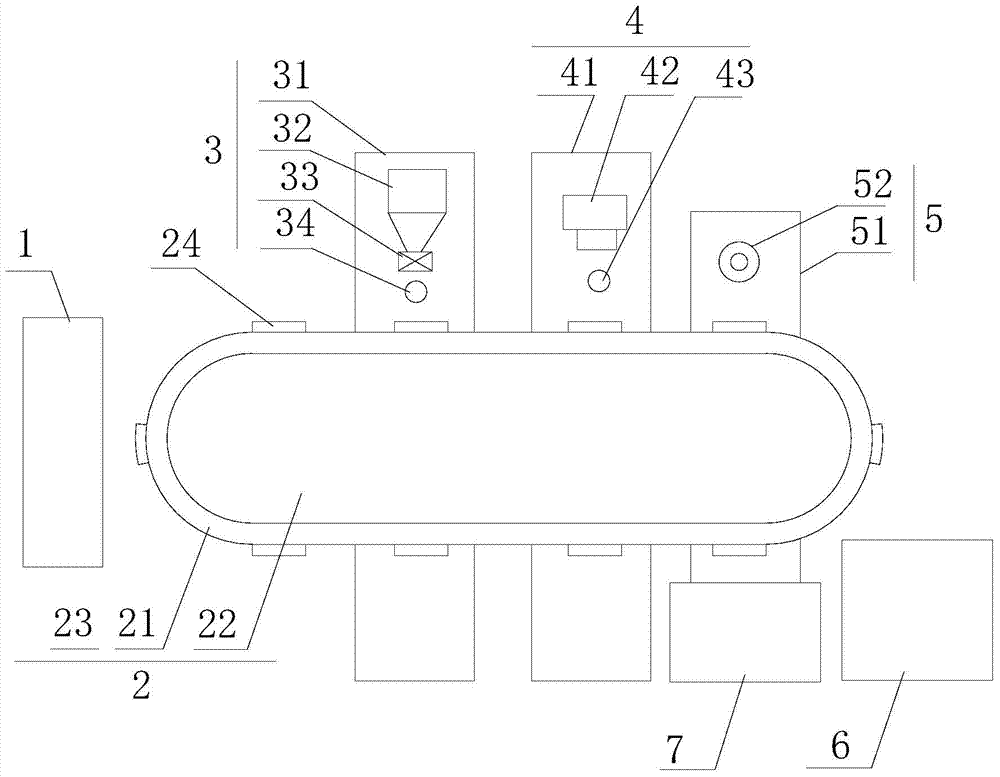

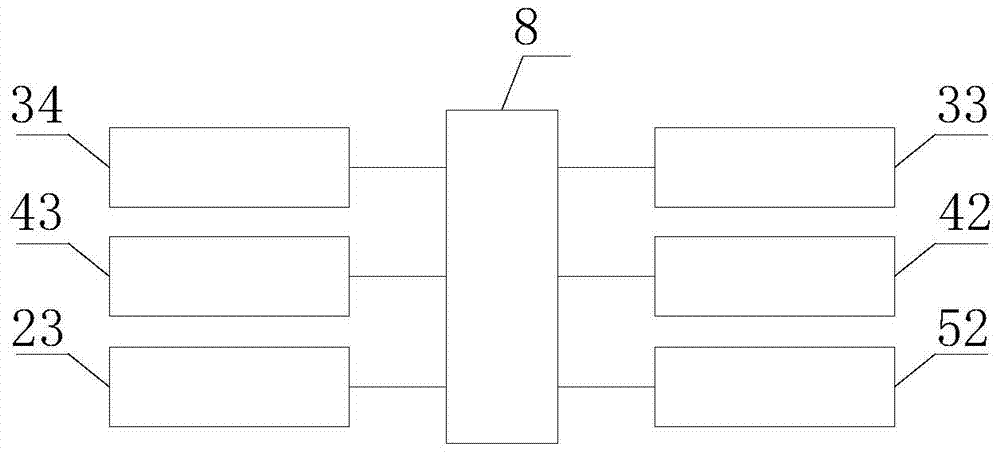

[0020] refer to figure 1 , figure 2 , a machine vision intelligent capsule filling system proposed by the present invention, comprising: a feeding mechanism 1, a capsule transmission mechanism 2, a filling mechanism 3, a packaging mechanism 4, a feeding mechanism 5, a first material bin 6, a second material Bin 7 and control module 8 .

[0021] The capsule transmission mechanism 2 includes a transmission belt 21 , a fixing seat 22 and a driving device 23 . The transmission belt 21 is rotatably looped on the upper surface and the lower surface of the fixed seat 22, and the transmission belt 21 is provided with a plurality of evenly distributed loading platforms 24 for carrying capsules. The driving device 23 is used to drive the transmission belt 21 to rotate.

[0022] In this embodiment, after loading the capsule, the loading table 24 drives the capsule to move on the upper surface of the fixing seat 22, so as to switch the capsule to a different position for processing. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com