Arm-muscle developer

一种臂力器、手柄的技术,应用在臂力器领域,能够解决使用不便等问题,达到使用舒适安全、尺寸小、弹力大的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

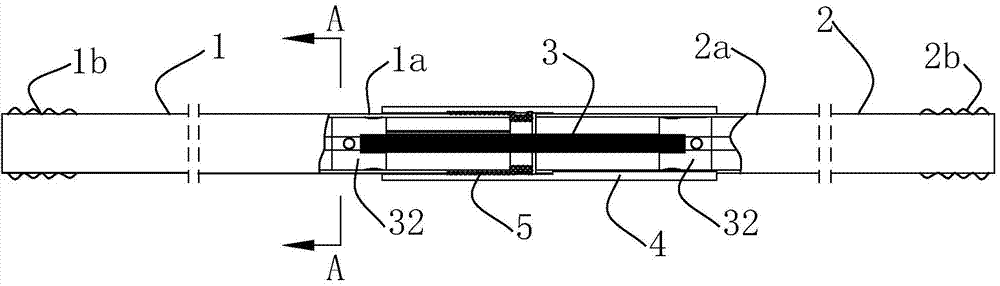

[0073] Such as figure 1 As shown, an arm strength device of the present invention includes left and right handles 1, 2, and each of the two handles 1, 2 includes a connecting end 1a, 2a and a gripping end 1b, 2b. The handle 1 in this embodiment , 2 is made of a metal pipe with an inner hole, such as a steel pipe or an aluminum alloy pipe. Among them, a torsion spring 3 is connected between the connecting ends 1a, 2a of the two handles. When the holding ends 1b, 2b of the two handles are held with both hands and rotated in opposite directions, the torsion spring 3 can provide torsional resistance , which can exercise the twisting force of the arms.

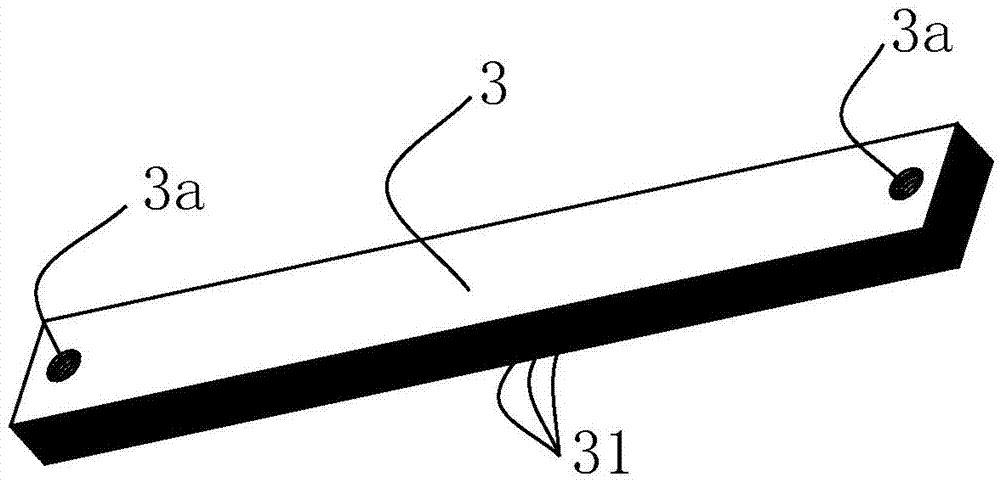

[0074] Such as figure 2 As shown, the torsion spring 3 in the present invention is composed of a plurality of spring steel sheets 31 overlapping up and down, and the two ends of these spring steel sheets 31 are provided with through holes 3a, which can be fixed by fasteners such as rivets or bolts. They are connected together. ...

Embodiment 2

[0079] Such as Figure 5 , Figure 6 As shown, in Embodiment 2 of the present invention, the two handles 1, 2 are U-shaped, the connecting ends 1a, 2a of the two handles are coaxially arranged, and the holding ends 1b, 2b of the two handles are arranged side by side, That is, viewed from the front, such as Figure 5 As shown, the holding ends 1b and 2b of the two handles overlap for a certain length, but they are separated by a certain distance in the free state. Viewed from the side, as Figure 10 As shown, an included angle is formed between the two handles 1 and 2. The structure of the torsion spring 3 in this embodiment, and the connection relationship between the torsion spring 3 and the two handles are the same as those in the first embodiment. Other structures, such as casing 4 and liner 5 can also be arranged in the same manner as in Embodiment 1.

[0080] The lengths of the two handles 1 and 2 are approximately the same. Since the holding ends 1b and 2b of the tw...

Embodiment 3

[0082] Such as Figure 7-9 As shown, the same as Embodiment 2, this embodiment also adopts two U-shaped handles and laminated torsion springs, and the two handles are also bent from round tubes, but in this embodiment, the torsion springs and the two The connection mode of the handle is different from that of Embodiment 2.

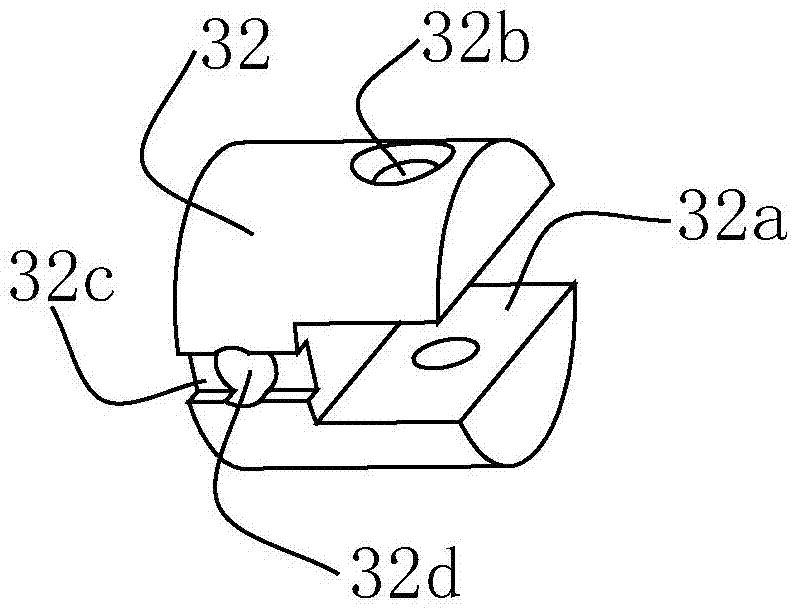

[0083] Such as Figure 7 Shown, one end of torsion spring 3 fixes a spring holder 32 in the present embodiment, and spring holder 32 is identical with above-mentioned two embodiments; Like the seat 32, a notch 33a is also provided on the spring holding seat 33, and one end of the spring steel sheet is clamped in the notch 33a, and is fixed on the spring holding seat by fasteners such as rivets or bolts. 33 on. A section of spline shaft 33b is also provided on the spring clamping seat 33, and external spline teeth are provided on the spline shaft 33b.

[0084] Such as Figure 8 As shown, the spring fixing seat 32 is fixed in the left handle 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com