Double-sided asymmetrical-structure flat support membrane and preparation method and application thereof

A flat-supported, asymmetric technology, applied in the field of membrane separation technology and new materials, can solve problems such as many structural defects, inability to use in a wider range, and inability to use for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0095] Example 1

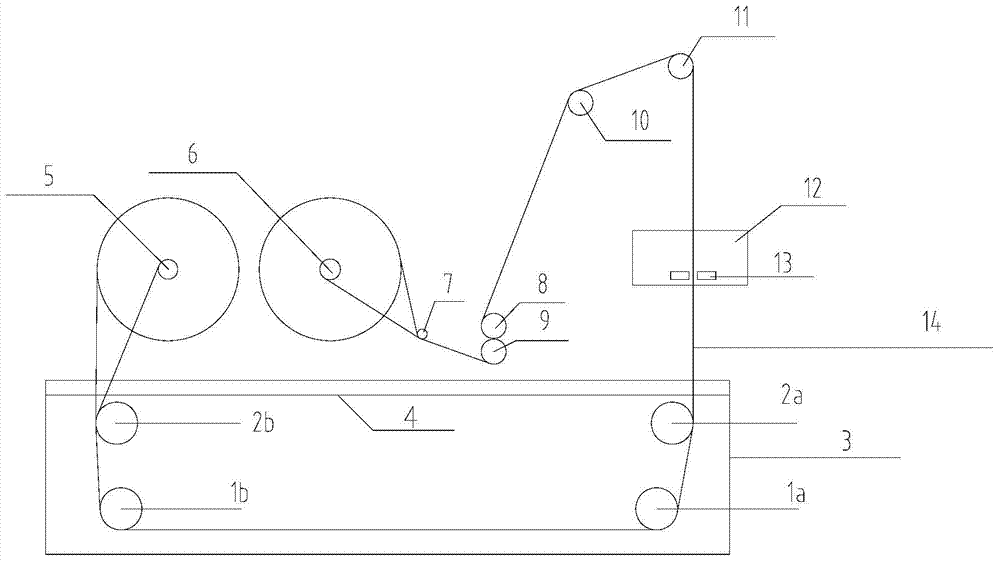

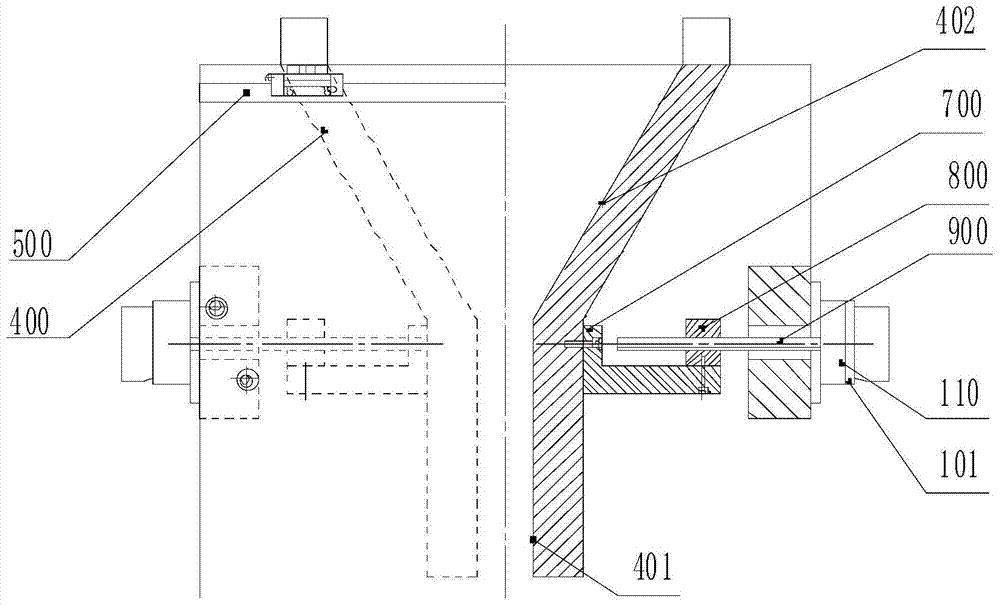

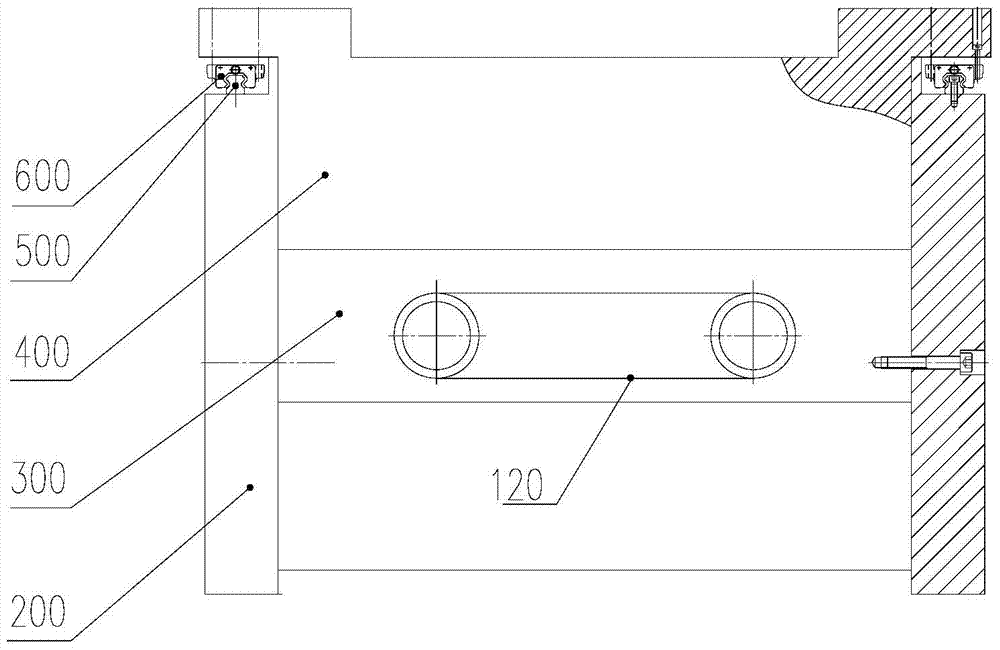

[0096] The prepolymer polyamic acid (PAA) of polyimide is mixed with solvent N,N-dimethylacetamide (DMAc) and additive acetone, heated and stirred at high speed to obtain 15% PAA+3% acetone casting Membrane liquid, the viscosity of the material liquid is 8000mPa·s; the polyethylene mesh with a width of 50cm and a mesh size of 200μm as a support is placed vertically in the middle of the film-forming surface of the film-forming mechanism, and is connected with a motor-driven winding roller. The width of the film-forming surface is set to 58cm, and the distance between the film-forming surfaces is set to 200 microns; the casting liquid is added to the middle of the film-forming surface of the film-forming mechanism, and it is still for 10 minutes; the motor is turned on and the support body passes through the film at a linear speed of 15m / h. Membrane mechanism, the casting liquid is cast on both sides of the support body to form a film. After staying in the air fo...

Example

[0098] Examples 2-9

[0099] Follow the steps of Example 1, but the casting solution is of the type given in Table 1, and the properties of the obtained double-sided asymmetric structure flat support film are shown in Table 1.

[0100] Table 1

[0101]

Example Embodiment

[0102] Example 10

[0103] Mix polyacrylonitrile (PAN) with solvent N-methylpyrrolidone (NMP), additive polyvinylpyrrolidone (PVP), heat and stir at high speed to prepare 22% PAN+10% PVP casting solution, the viscosity of the material liquid is 92400mPa ·S. The stainless steel with a width of 100cm and a mesh size of 50μm is placed vertically in the middle of the film-forming surface of the film-forming mechanism and connected to the motor-driven winding roller. The film-forming surface width is set to 108cm, and the film-forming surface is straight. The spacing is set to 300 microns; the casting liquid is added to the middle of the film forming mechanism of the film forming mechanism, and it is static for 25 minutes; the motor is turned on, the support body passes through the film forming mechanism at a linear speed of 5m / h, and the casting film liquid runs in the film forming mechanism with the support body. The two sides are cast to form a film. After staying in the air for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Mesh size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com