Exothermic reaction device and method for accurately determining temperature in reaction process

A technology of exothermic reaction and reaction kettle, which is applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of inability to ensure accurate positioning of the reactor temperature, unavoidable side effects of the reactor, and limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

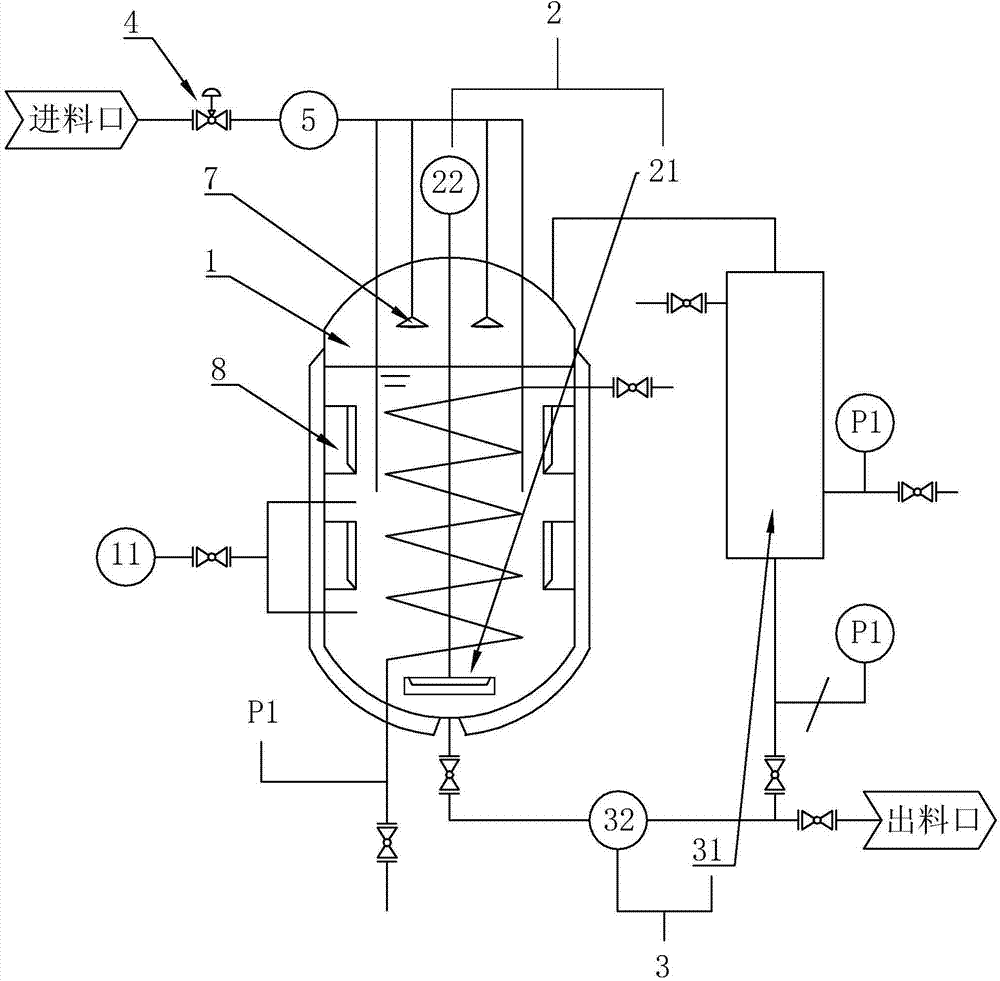

[0029] refer to figure 1 The exothermic reaction device and the embodiment of the method for accurately determining the temperature during the reaction process of the present invention will be further described.

[0030] An exothermic reaction device, comprising a reactor 1, a stirring device 2, a PLC for setting the temperature control range required by the process, and a condensation device 3 for taking away the reaction temperature in the reactor 1, the top of the reactor 1 is A dripping liquid pipeline is provided, and a flow regulating valve 4 and a mass flow meter 5 controlled by PLC are arranged on the dripping liquid pipeline, and a multi-point temperature sensor 6 that transmits signals to the PLC is built in the reaction kettle 1, The bottom of the reactor 1 is provided with a protective gas inlet 11 . The reaction kettle 1 is used for mixing two or more reaction solutions, the stirring device 2 is used for fully mixing two or more reaction solutions, and the temper...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap