A preparation method and device for reducing the magnetic declination angle of sintered NdFeB

A magnetic declination and NdFeB technology, which is applied in the field of preparation and device for reducing the magnetic declination of sintered NdFeB, can solve the problems of uncontrollable production, reduction of magnetic declination of magnets, and damage of magnet performance, so as to improve the material Effects of Utilization, Declination Angle Reduction, and Capability Enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

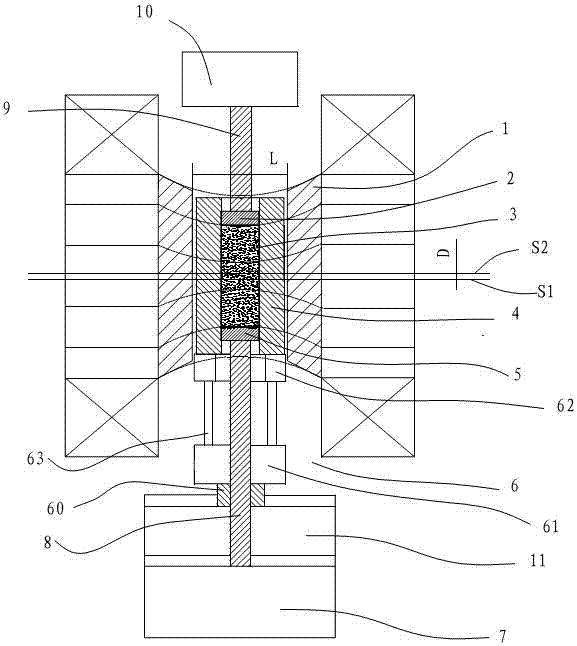

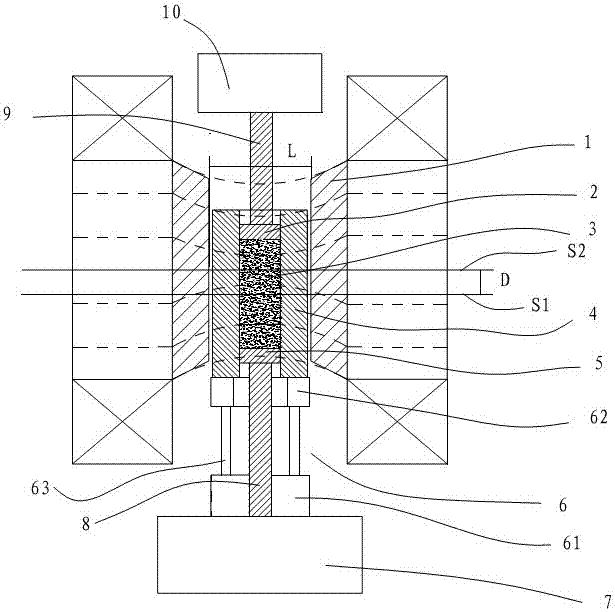

Method used

Image

Examples

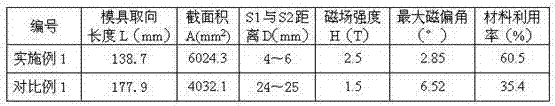

Embodiment 1

[0021] The finished product specification is 20mm×4mm×9mm↓ (orientation direction), the production process of the brand N40 product.

[0022] Ingredients: according to the following composition ratio weight ingredients, praseodymium neodymium alloy 30.2% by weight, gadolinium 2.0% by weight, boron 1.03% by weight, aluminum 0.64% by weight, zirconium 0.3% by weight, copper 0.02% by weight, and the balance is iron and other impurities, Wherein in the praseodymium neodymium alloy, praseodymium accounts for 25% by weight, neodymium accounts for 75% by weight, boron is added in the state of BFe alloy, the boron content is 19%, and the iron content is 81%; Gadolinium is added in the state of GdFe alloy, and the content of gadolinium is 75%. The iron content is 25%.

[0023] Melting: Put the prepared raw materials into a vacuum induction furnace, vacuum the induction furnace to 4.5-5Pa, heat and melt until the raw materials in the furnace turn red, close the vacuum valve, fill in arg...

Embodiment 2

[0042] The finished product specification is Φ100mm×3mm↓ (orientation direction), the production process of the brand N38 product.

[0043] Ingredients: According to the following composition ratio weight ingredients, praseodymium neodymium alloy 31% by weight, gadolinium 2.5% by weight, boron 1.02% by weight, aluminum 0.64% by weight, zirconium 0.1% by weight, copper 0.02% by weight, and the balance is iron and other impurities, Wherein in the praseodymium neodymium alloy, praseodymium accounts for 25% by weight, neodymium accounts for 75% by weight, boron is added in the state of BFe alloy, the boron content is 19%, and the iron content is 81%; Gadolinium is added in the state of GdFe alloy, and the content of gadolinium is 75%. The iron content is 25%.

[0044] Melting: Put the prepared raw materials into the vacuum induction furnace, vacuum the induction furnace to 4.0-4.5Pa, heat and melt until the raw materials in the furnace turn red, close the vacuum valve, fill with a...

Embodiment 3

[0063] The finished product specification is Φ21mm×3mm↓ (orientation direction), the production process of the brand N45 product.

[0064] Ingredients: Ingredients are prepared according to the weight ratio of the following ingredients: 28% neodymium, 1.02% boron, 1.0% dysprosium, 1.5% holmium, 0.2% aluminum, 1.5% gadolinium, 0.4% niobium, 0.2% copper, 0.2% cobalt, 0.1% gallium , iron and other impurities are 65.88%, of which boron is added in the state of BFe alloy, the content of boron is 19%, and the content of iron is 81%; holmium is added in the state of alloy with HoFe purity of 99.50%, the content of holmium is 80%, and the content of iron is 20% Gadolinium is added in the state of GdFe alloy, the content of gadolinium is 75%, and the content of iron is 25%; niobium is added in the state of NbFe alloy, of which the content of niobium is 65% and the content of iron is 35%.

[0065] Melting: Put the prepared raw materials into the vacuum induction furnace, vacuum the induct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com