Drive axle gearbox wheel set for large railway maintenance machinery

A technology of large-scale road maintenance machinery and axle gearboxes, which is applied to railway car body parts, axle boxes, wheels, etc., can solve the problems of inability to move, 1435mm drive axle gearboxes cannot be matched to meet different gauges, etc., and achieve stable and reliable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

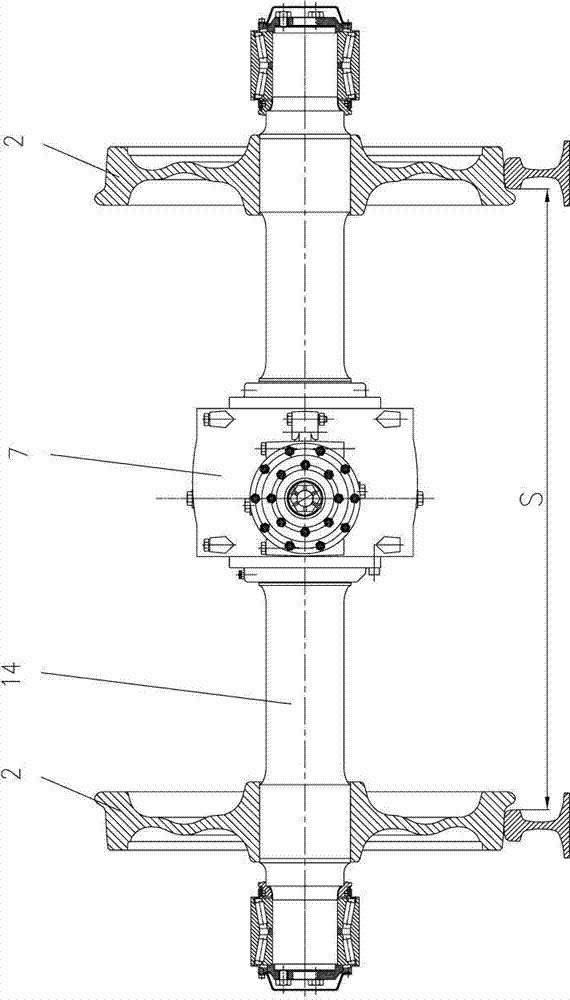

[0019] Such as figure 1 As shown, the fixed-gauge driving axle gearbox wheel set in the prior art includes an axle 14, a driving axle gearbox 7 and two wheels 2, and the two wheels 2 are respectively interference fit and fixed on the wheel seats at both ends of the axle 14. superior.

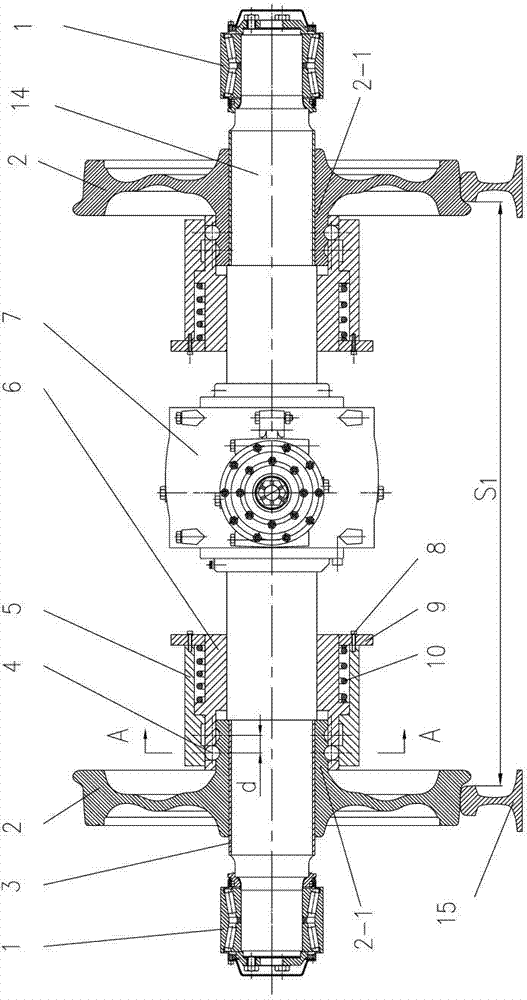

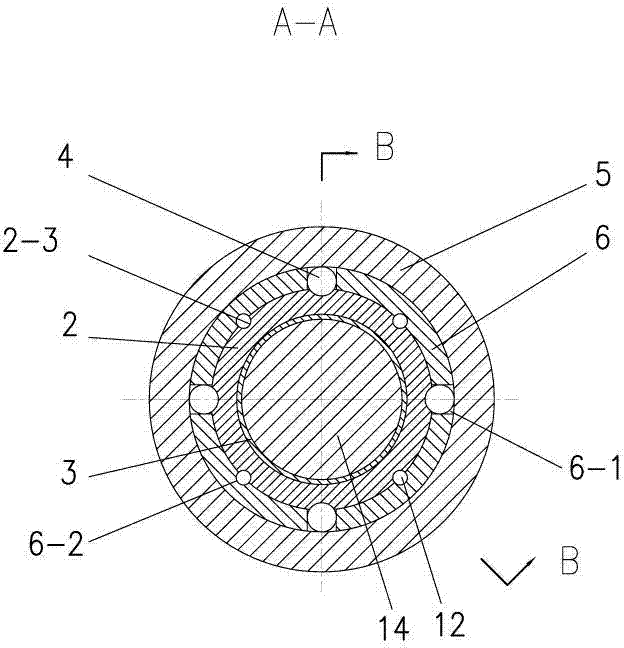

[0020] Such as Figure 2-6 Shown, a kind of driving axle gear box wheelset of railway large-scale road maintenance machinery of the present invention comprises axle 14, two wheels 2, and described two wheels 2 are respectively located on the wheel seat at the two ends of axle 14, also comprises sliding bearing 3. Locking steel ball 4, inner sleeve 6, outer sleeve 5, rolling steel ball 12, retaining ring 11 for shaft, retaining ring 13 for hole, spring 10 and end cap 9; the two wheels 2 all have The wheel hub 2-1 extending to the middle of the axle shaft 14, the outer circle of the wheel hub 2-1 is milled with at least two rows of spherical grooves 2-2 and several rows of axial first semicircul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com