Normally-closed strip-shaped slip chuck for small cylinder spring set

A slip chuck and spring group technology, which is applied to drilling equipment, earth-moving drilling, drill pipe and other directions, can solve the problems of inconvenient installation and operation, elastic elements cannot meet the requirements of high-capacity chucks, etc., and achieves convenient disassembly of drilling tools. , The effect of preventing water and debris from entering the chuck and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

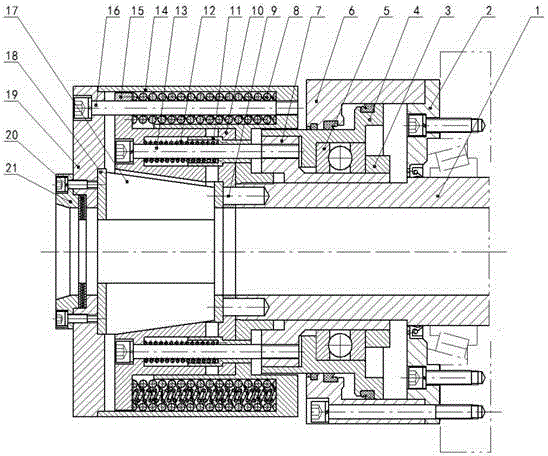

[0018] The present invention will be further described below in conjunction with accompanying drawing:

[0019] The small cylindrical spring group normally closed strip slip chuck is composed of four parts: the fixed unit assembly, the slip rotation unit assembly, the fixed rotation separation unit assembly and the drill pipe water and dust blocking unit assembly. The principle of ramp force is adopted to amplify the tension of the spring.

[0020] The fixed unit includes the positioning bearing cover 2, the chuck cylinder body 6, the cylinder piston 4 and the cylinder seal, which are generally installed at the end of the body to form a large ring hydraulic cylinder. Loosen the slips and adjust the large ring hydraulic cylinder. The design parameters can easily solve the matching problem with the hydraulic system parameters, and effectively realize the functional linkage of the executive components.

[0021] The slip rotation unit includes a main shaft 1, a sliding mandrel 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com