Adhesive pre-applying and label pre-cutting dry type labeling machine

A labeling machine and pre-applied glue technology, applied in the mechanical field, can solve the problems of legacy, bottle pollution, metal knife consumption of large binder, etc., to achieve the effect of enhancing selectivity and eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

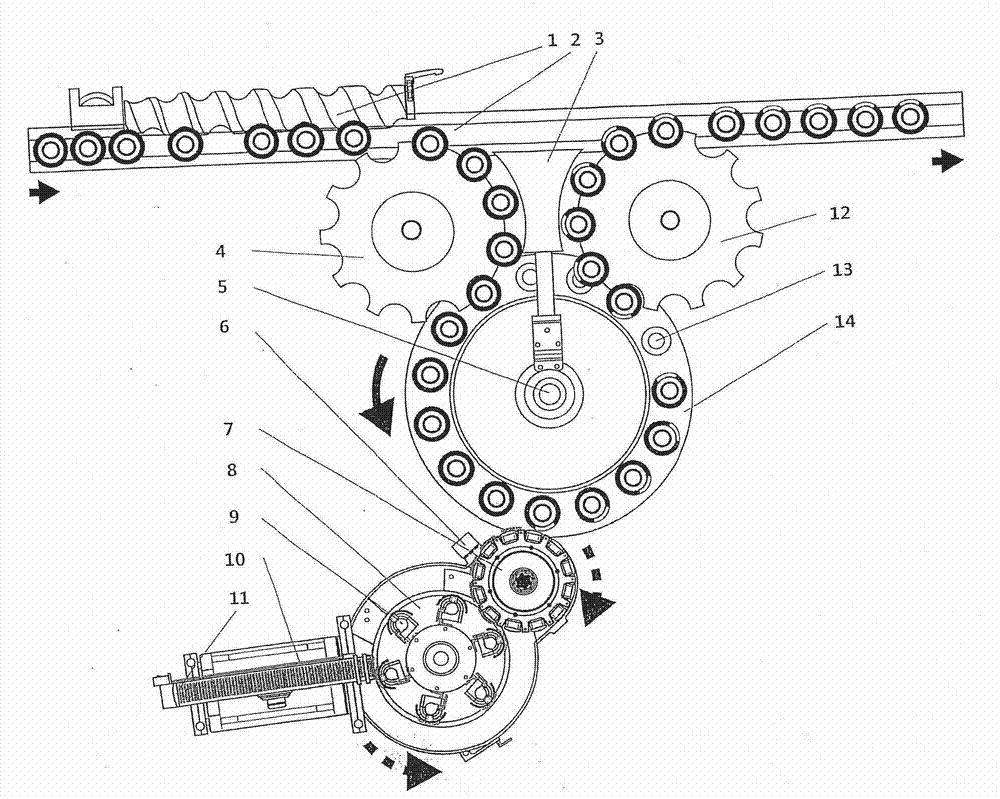

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

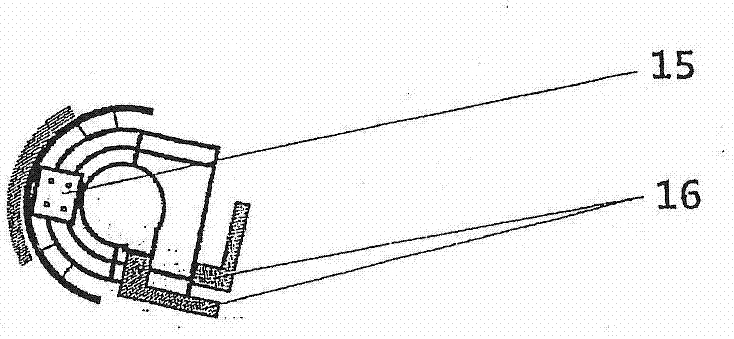

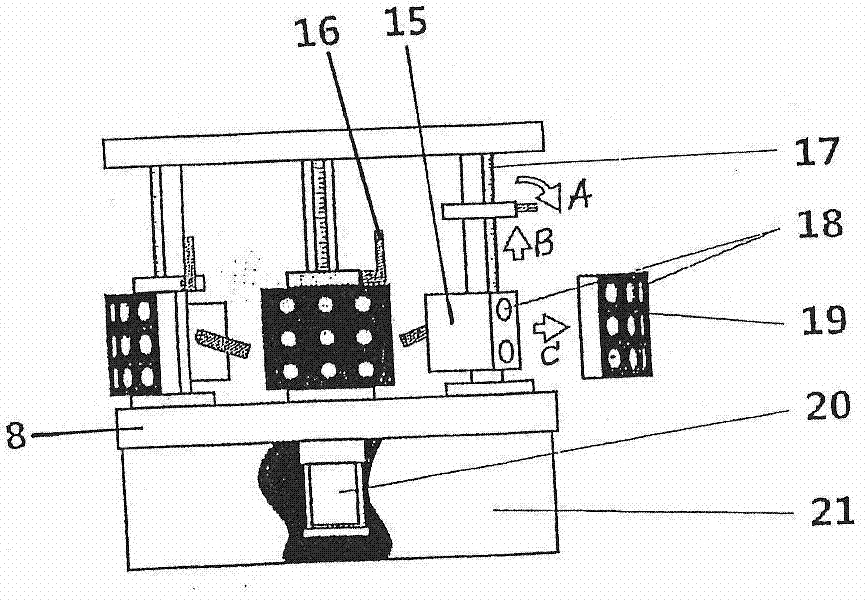

[0044] A pre-glue and pre-cut labeling dry labeling machine, which consists of a platform, a screw 1, a chain 2, a guide plate 3, a star wheel 4, a turntable shaft 5, a spray device 6, a drum 7, a label suction turntable 8, Standard palm 9, standard storage tray 10, standard pressing plate 11, B star wheel 12, bottle holder 13, turntable 14, suction suction device 15, buckle handle 16, scale 17, standard suction hole 18, standard support plate 19, Motor 20, guard plate 21 constitute;

[0045]The pre-glue and pre-cut label dry labeling machine, one side of the platform and the chain 2, one side of the chain 2 and the screw 1, the platform and the guide plate 3 and the axis of the A star wheel 4 and the turntable shaft 5 And the axis of spraying device 6 and rotating drum 7 and the axis of label suction turntable 8 and the axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com