Multilayer synchronous lifting equipment

A technology of synchronous lifting and equipment, applied in the direction of transportation, packaging, conveyors, etc., can solve the problems of large production site area, prone to failure, low positioning accuracy, etc., to reduce production costs, ensure stability, and avoid bending Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

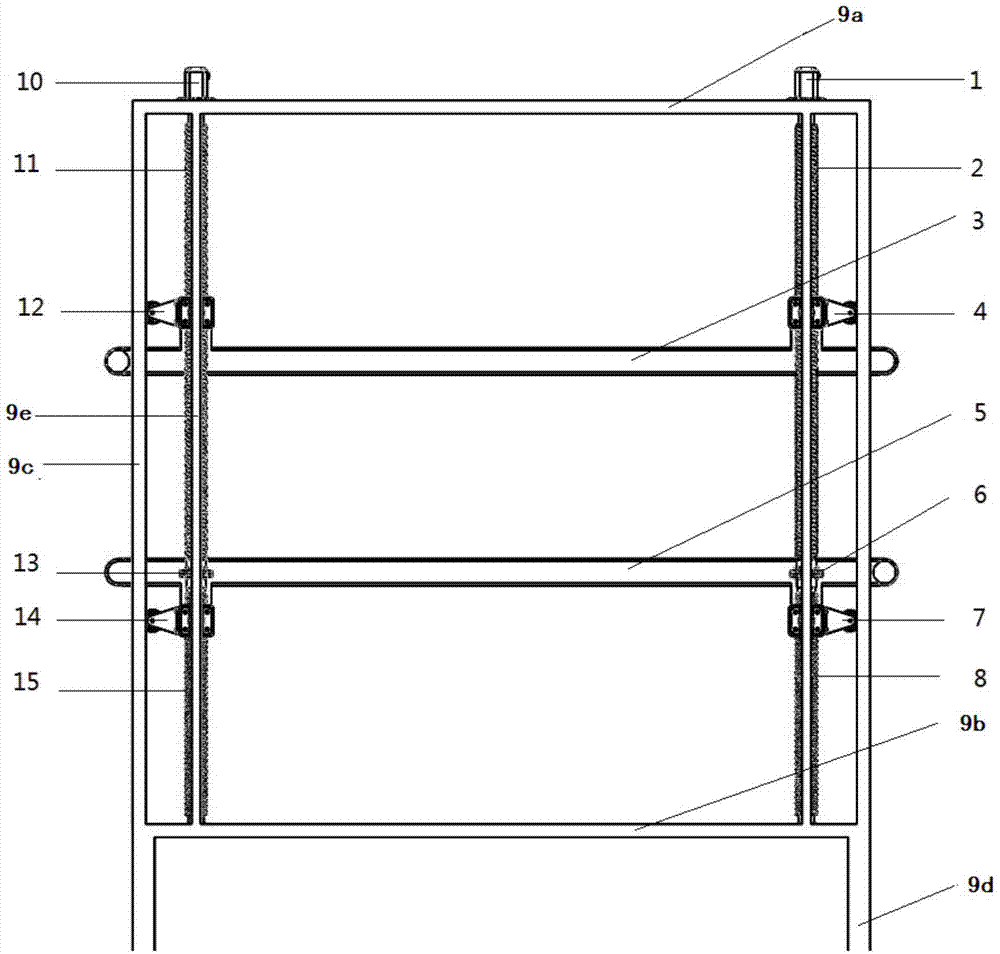

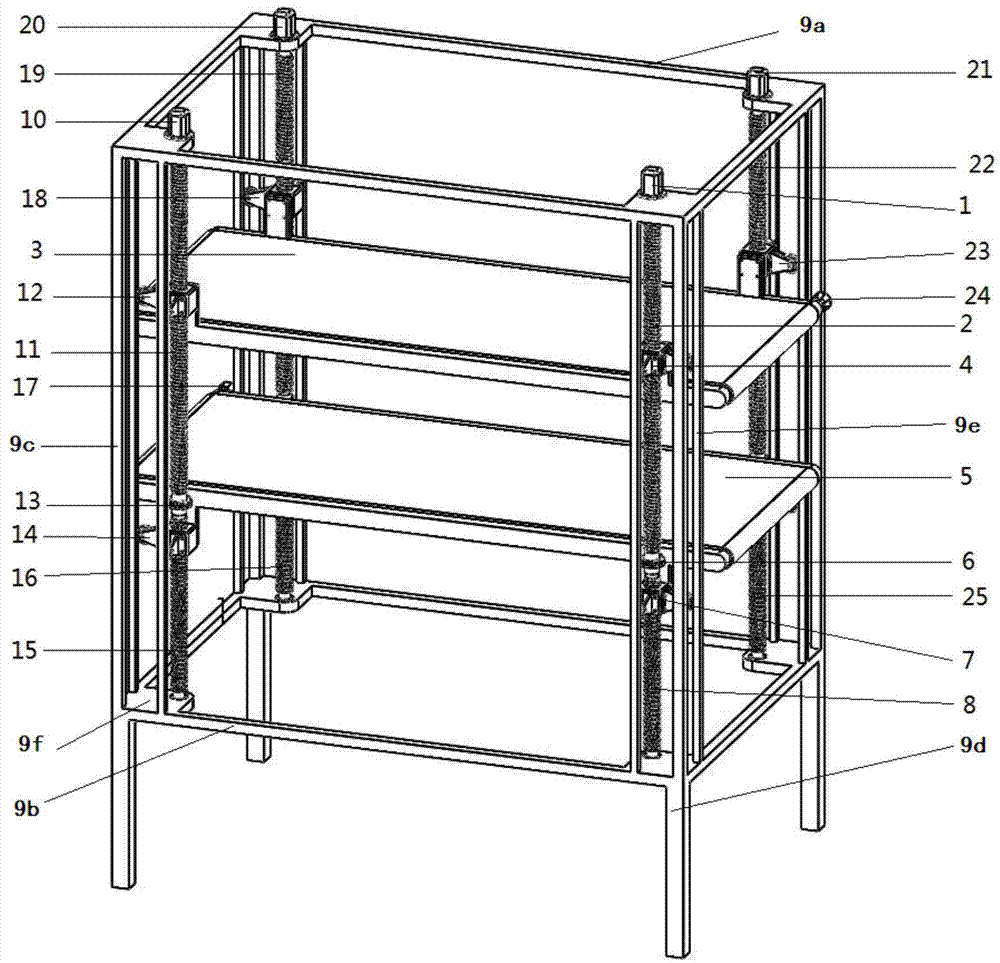

[0028] In this example, if figure 1 and figure 2 As shown, a multi-layer synchronous lifting equipment is set:

[0029] A supporting skeleton mechanism is made up of four support rods 9c between the four vertexes of the upper rectangular frame 9a, the lower rectangular frame 9b and the four vertexes of the lower rectangular frame 9b connected to the upper rectangular frame 9a; The support rods are formed with support feet 9d at the bottom of the lower rectangular frame; roller support rods 9e are respectively arranged between the upper rectangular frame 9a and the lower rectangular frame 9b on both sides of the four support rods 9c; that is, any adjacent two support A pair of roller support rods are arranged between the rods; corner connectors 9f connecting two adjacent sides are arranged on the four corners of the upper rectangular frame 9a and the lower rectangular frame 9b;

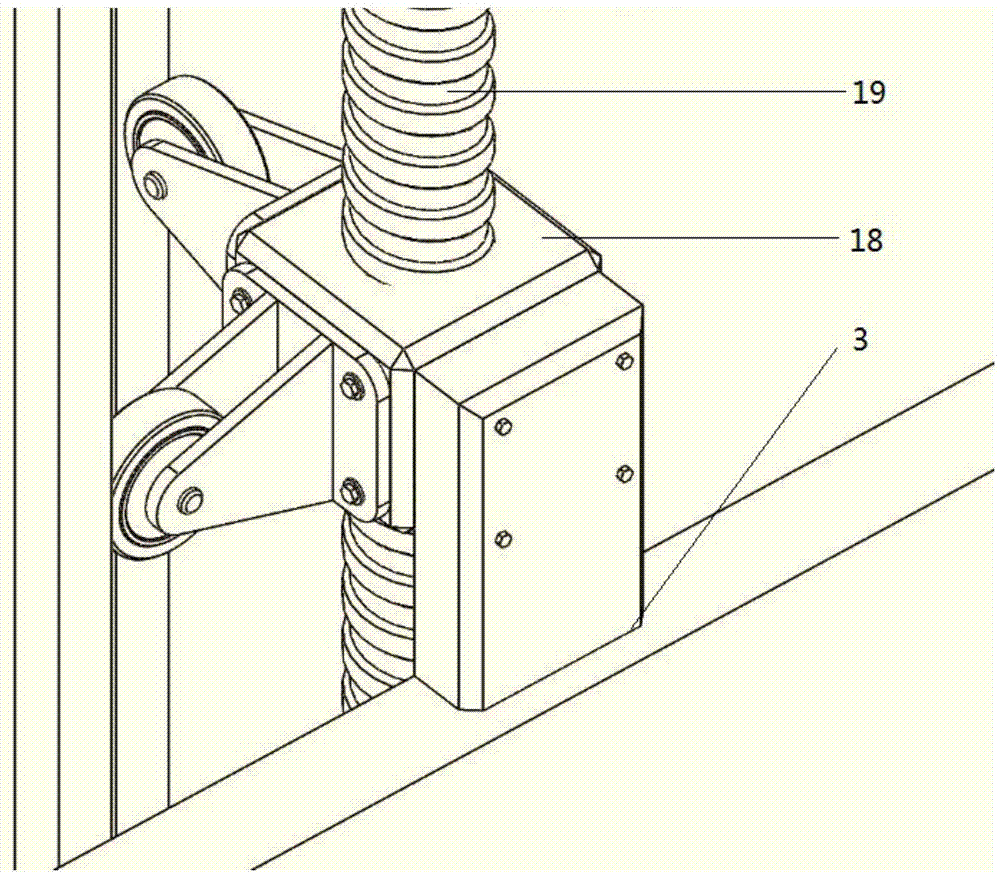

[0030] A lifting mechanism; it is composed of a servo motor, a transmission screw group and a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com