Conveyor and control method

A technology of conveying device and control method, applied in the fields of transportation and operation, can solve problems such as affecting production efficiency, inability to precisely control, and uncertain motion trajectory, and achieve the effects of easy operation and maintenance, improved qualification rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention are described in detail below:

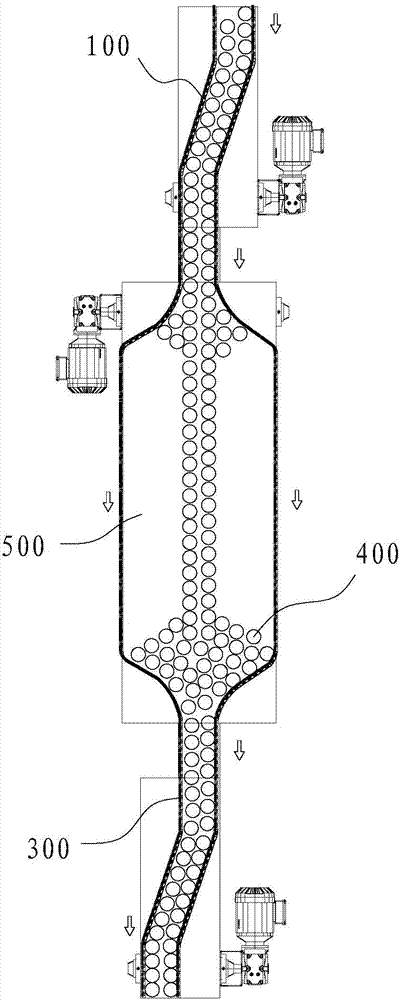

[0038] figure 1 It is a structural schematic diagram of the existing bottle storage platform, and the bottles that cannot be sent away in time can be accumulated on the bottle storage platform 500 .

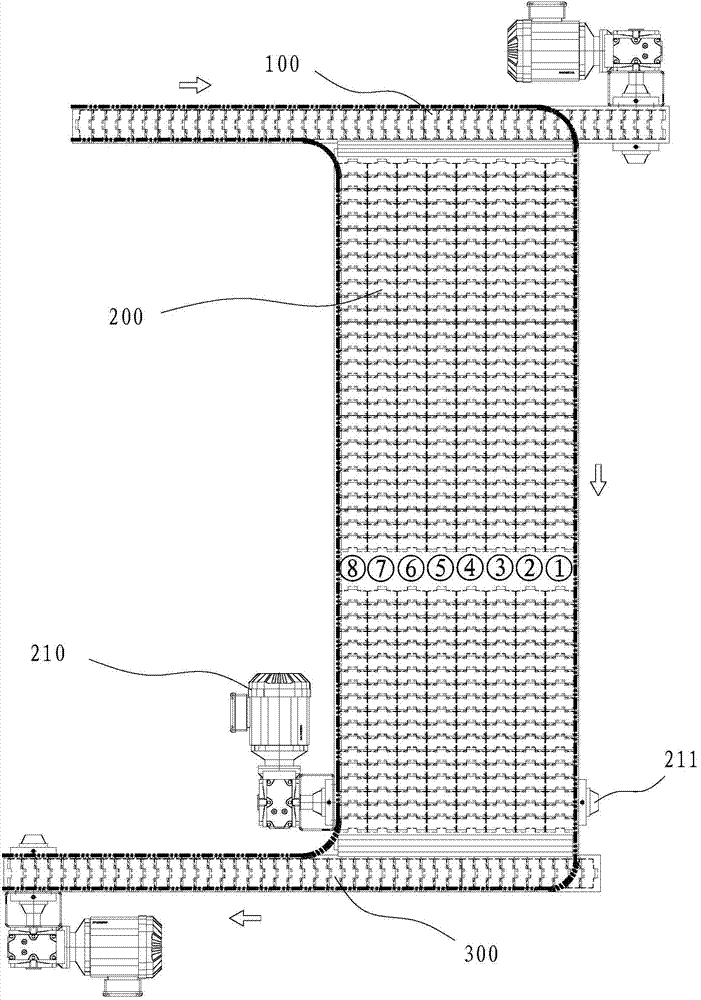

[0039] like Figures 2 to 3 As shown, the conveying device has an input channel 100, an output channel 300, and a plurality of buffer conveyors 200, and the buffer conveyors 200 are arranged in parallel, and the buffer conveyor 200 has an input port and an output port, and each input port is arranged in parallel. The same side is vertically connected, and the output ports are arranged in parallel and connected to the same side of the output channel 300 , and the input channel 100 and the output channel 300 are arranged at both ends of the buffer conveyor 200 .

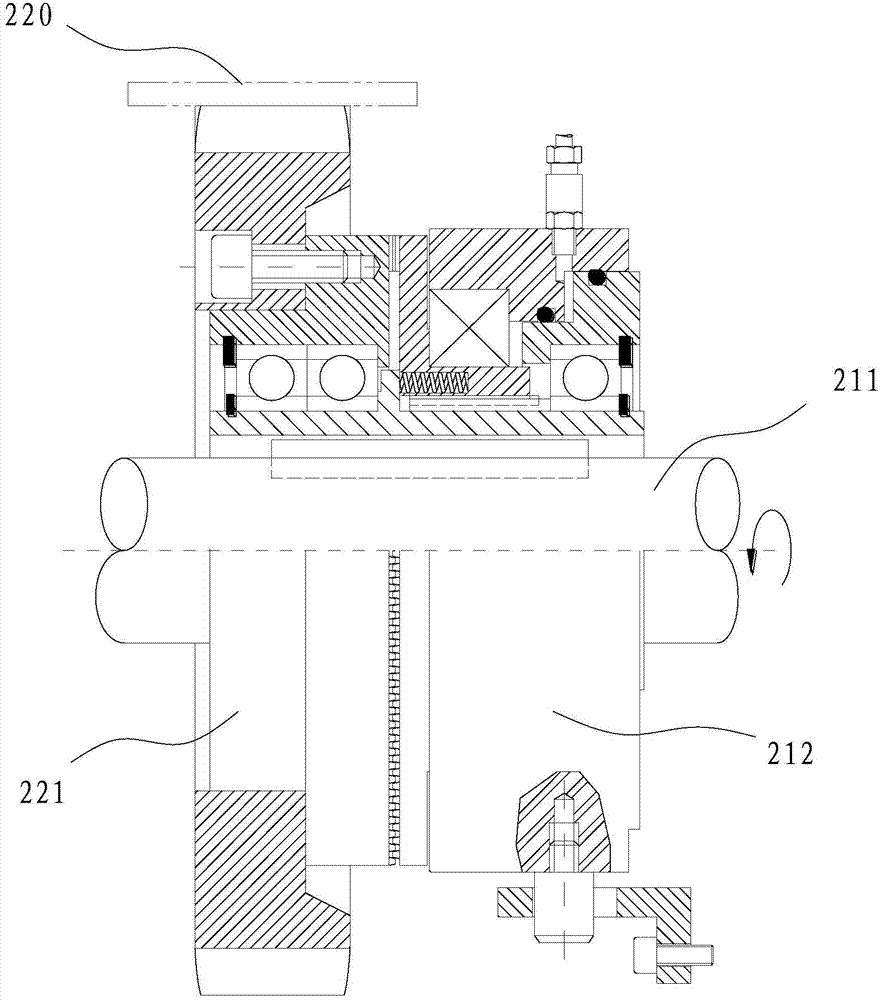

[0040] It also includes a first guide plate 601 and a second guide plate 602. The first guide plate 601 transitions from the conveying direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com