Pipe core skid resistance anchoring device for vertical wire wrapping machine for prestressed concrete cylinder pipe

A technology of prestressed steel and concrete pipes, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., which can solve the problems of pipes losing pressure resistance, pressure plate not being able to press the pipe core, and prestressing unable to be applied, etc. Reliable anchoring effect, improved pressure bearing capacity and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

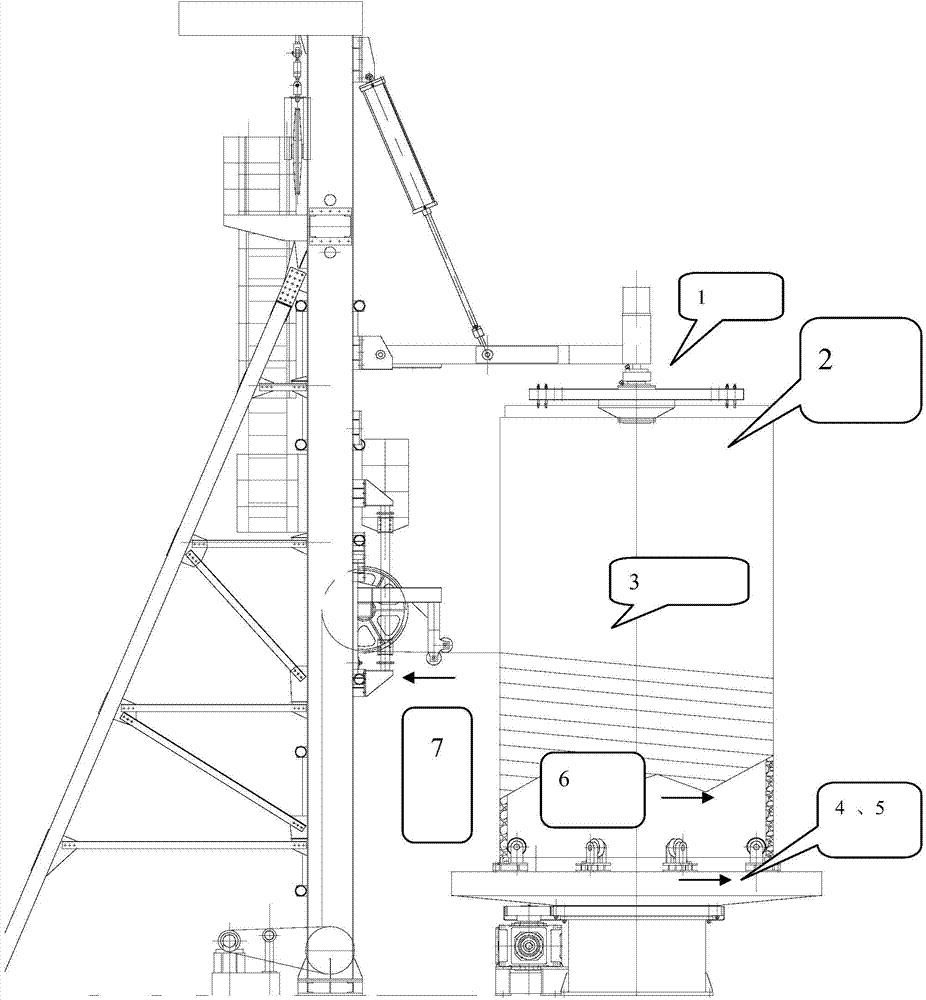

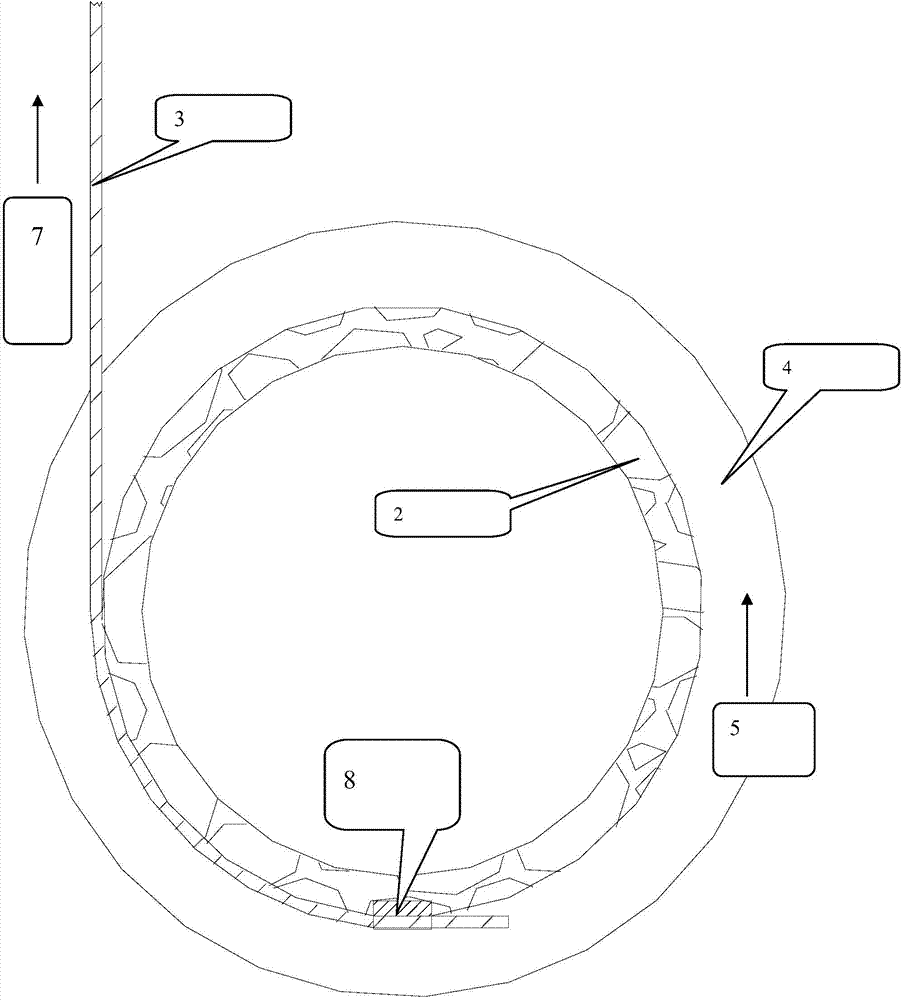

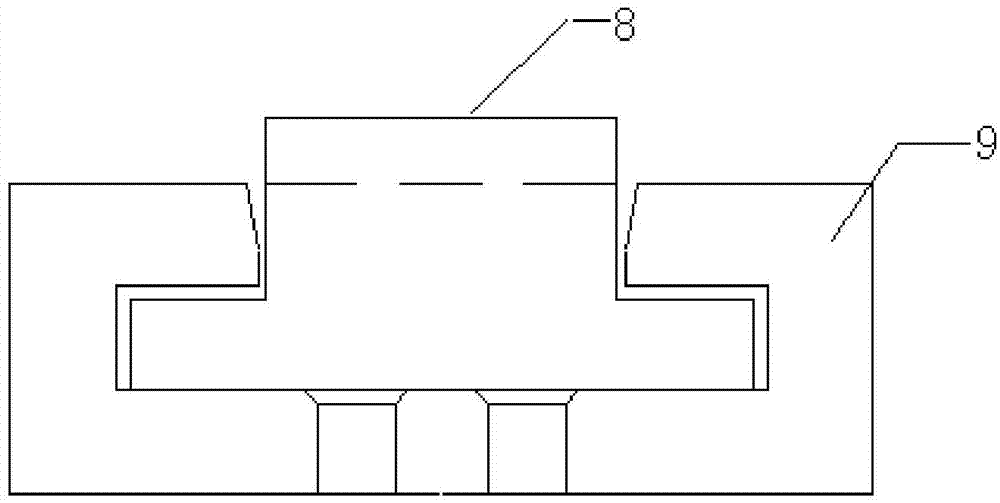

[0028] like Figure 3-8 Shown: a vertical prestressed steel tube concrete tube wire winding machine tube core anti-slip anchor, which is composed of an anchor base 9 and an anchor block 8. The base of the anchor is fixed on the base of the core positioning wheel of the rotating platform of the wire winding machine with screws; the protrusion 10 on the anchor block is embedded in the groove 11 of the base, and a plurality of In the tooth groove 12 embedded in the prestressed steel wire.

[0029] During production, the base of the anchor is fixed on the base of the core positioning wheel of the rotating platform of the wire winding machine with screws. In the groove, then the prestressed steel wire is embedded in the tooth groove of the anchor block 13 on the tube core, so that the anchoring work of the tube core has just been completed, and the machine can be started to wrap the wire.

[0030] The invention uses the prestressed steel wire embedded in the anchor block to limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com