Inner clamping type hoisting device for braking drum of automobile

A technology of automobile braking and lifting devices, which is applied in the direction of transportation, packaging, and load hanging components, etc., can solve the problems of easy decoupling, safety, and low lifting efficiency, and achieve high safety factor, long service life, and high lifting efficiency. The effect of high transport efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The content of the present invention will be described below in conjunction with specific embodiments.

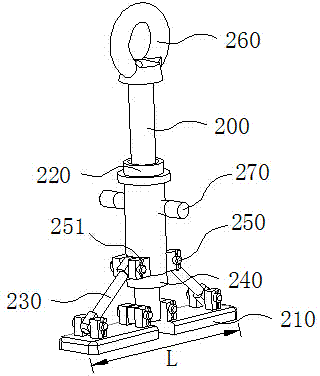

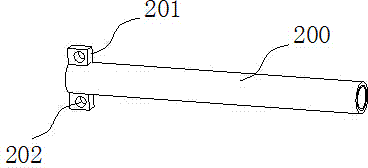

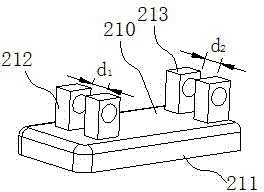

[0033] Such as figure 1 As shown, it is a schematic diagram of the structure of the lifting device for the automobile brake drum according to the present invention, and the lifting device is used for lifting the brake drum 100 . The lifting device comprises: a suspension shaft 200, a clamping plate 210, a sleeve 220, a pull rod 230, a positioning ring 240, a pin shaft 250, a suspension ring 260 and a handle 270, and a suspension ring 260 is installed at the upper end of the suspension shaft 200. Lift the suspension shaft 200, and install two mutually symmetrical clamping plates 210 at the lowermost end of the suspension shaft 200. A sleeve 220 and a positioning ring 240 are set on the suspension shaft 200. The positioning ring 240 ensures the installation of the sleeve 220. position. A pull rod 230 is also provided between the sleeve 220 and the clamping plate 210 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com