Wind load control system, method and apparatus and hoisting equipment

A lifting equipment and control system technology, applied in cranes, transportation and packaging, load hanging components, etc., can solve the problems of inaccurate control results and too general control methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

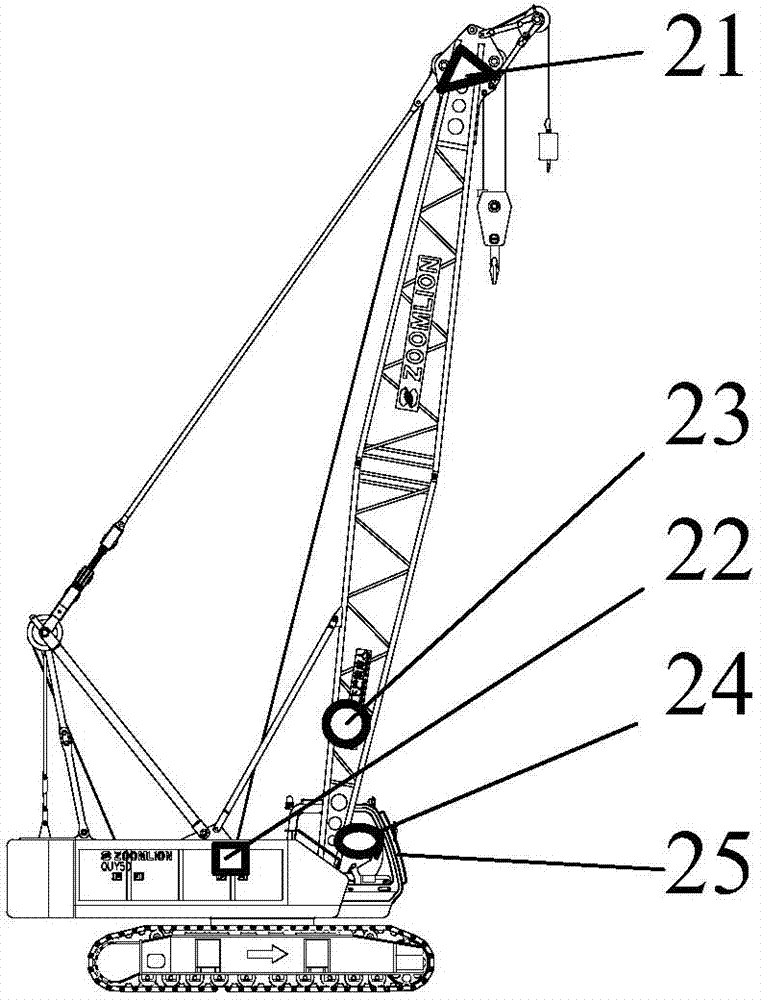

[0030] Embodiment 1 of the present invention provides a wind load control system, such as figure 2 As shown, it is a schematic structural diagram of the wind load control system in Embodiment 1 of the present invention, and the wind load control system may include:

[0031] The wind speed measuring device 21 can be used to measure the current wind speed of the jib head of the lifting equipment, that is, measure the current wind speed of the jib head of the lifting equipment;

[0032] The hook position measuring device 22 can be used to measure the current hook position of the lifting device, that is, measure the current position of the hook of the lifting device, wherein the current position of the hook of the lifting device usually refers to the hook position of the lifting device. The height of the hook from the horizontal plane where the lifting device is located;

[0033] The jib elevation angle measuring device 23 can be used to measure the current jib elevation angle o...

Embodiment 2

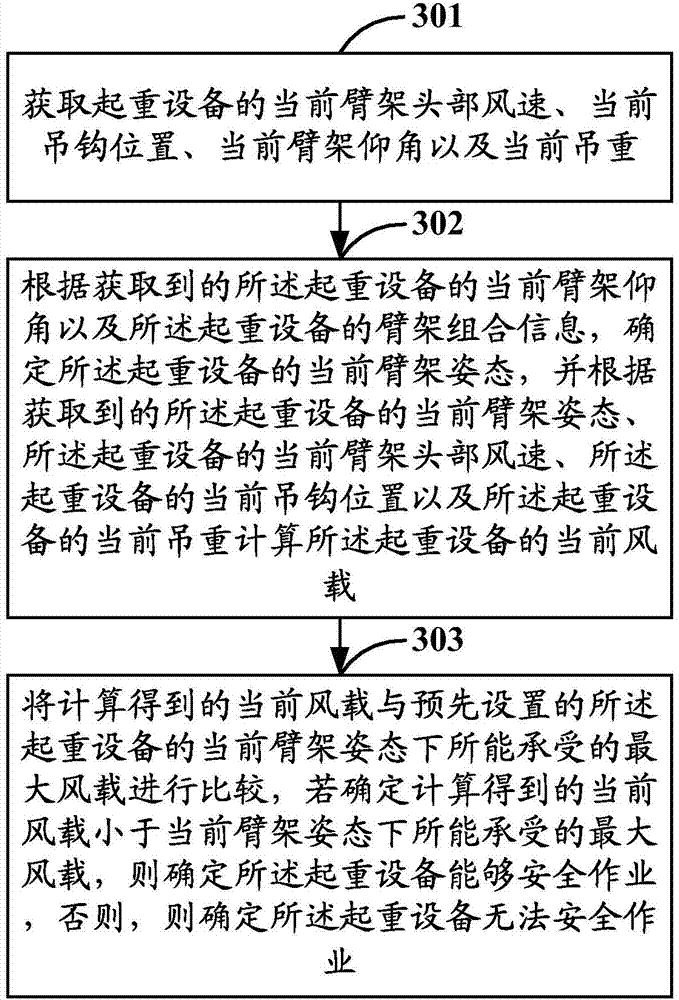

[0062] Based on the same inventive concept, Embodiment 2 of the present invention provides a wind load control method, such as image 3 As shown, it is a schematic flow chart of the wind load control method described in Embodiment 2 of the present invention, and the wind load control method may include the following steps:

[0063] Step 301: Obtain the current wind speed at the head of the jib, the current position of the hook, the current elevation angle of the jib, and the current hoisting weight of the lifting device.

[0064] Specifically, the execution subject of each step in Embodiment 2 of the present invention may generally be the wind load control device described in Embodiment 1 of the present invention, which will not be described in detail in this embodiment of the present invention.

[0065] Optionally, obtaining the current wind speed at the head of the jib, the current position of the hook, the current elevation angle of the jib, and the current lifting weight o...

Embodiment 3

[0099] Based on the same inventive concept, Embodiment 3 of the present invention provides a wind load control device, such as Figure 4 As shown, it is a schematic structural diagram of the wind load control device in Embodiment 3 of the present invention, and the wind load control device may include:

[0100] The obtaining module 41 can be used to obtain the current wind speed at the head of the jib, the current position of the hook, the current elevation angle of the jib and the current hoisted weight of the lifting equipment. Optionally, the acquiring module 41 can be specifically configured to acquire the current wind speed at the jib head of the lifting equipment from the anemometer located at the jib head of the lifting equipment, The current hook position of the lifting device is obtained from the angle encoder, the current jib elevation angle of the lifting device is obtained from the angle sensor located at the bottom of the jib of the lifting device, and the startin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com